A PFAS Journey to Determine Effective Management and Treatment Options

A PFAS Journey to Determine Effective Management and Treatment Options

Tata & Howard is working with the Town of Shrewsbury, MA to address perfluoroalkyl and polyfluoroalkyl substances (PFAS) in the groundwater. The Town of Shrewsbury water system serves a population of approximately 38,300. The system consists of about 200 miles of main, nine active groundwater wells from three well sites, three pressure zones, six storage tanks, and one water treatment plant. The 7.0 million gallon per day (mgd) Home Farm Water Treatment Facility utilizes biological treatment for removal of manganese.

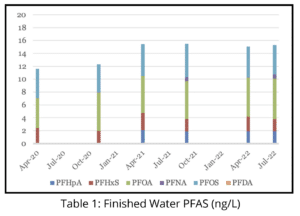

In 2020, Shrewsbury detected PFAS in the wells. Sampling has indicated that PFAS is present in most of the wells operated by the Town but under the maximum contaminant level (MCL) of 20 nanograms per liter (ng/L) for PFAS6 as regulated by the Massachusetts Department of Environmental Protection (MassDEP) which includes the sum of concentrations for PFOS, PFOA, PFHxS, PFNA, PFHpA, and PFDA. Raw water from one well site, the Sewell Well, has been consistently higher than 20 ng/L; but the finished water from all wells after treatment at the Home Farm Water Treatment Plant has been in compliance and consistently less than 16 ng/L. Most of the PFAS is in the form of PFOA and PFOS which are the two compounds for which the EPA has developed a proposed MCL. The PFOA indicated by the green bar in Table 1 is higher than the proposed Federal MCL of 4 ng/L.

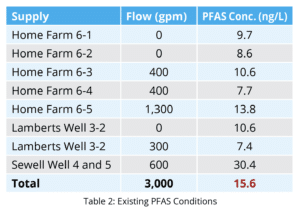

Currently, the Town has been managing the sources to improve water quality and stay under the current MCL of 20 ng/L for PFAS6. A mass balance is utilized to estimate finished water PFAS concentrations based on updated sample results and changes in the operation of the sources. Tata & Howard created the base tool which can be used to see how changes to PFAS levels or flow rates can affect the finished water concentration.

Currently, the Town has been managing the sources to improve water quality and stay under the current MCL of 20 ng/L for PFAS6. A mass balance is utilized to estimate finished water PFAS concentrations based on updated sample results and changes in the operation of the sources. Tata & Howard created the base tool which can be used to see how changes to PFAS levels or flow rates can affect the finished water concentration.

Table 2 represents existing conditions. The numbers used for PFAS are the highest results from each individual well observed in a year of sampling data, showing the finished water level is about 16 ng/L. As long as the PFAS concentrations in the wells remain consistent, the Town will remain in compliance. If sample results change and they see an increase in PFAS concentration at Sewell, the Town will make adjustments using the mass balance to manage the sources to remain in compliance.

The Town cannot manage sources like this indefinitely. They decided to move forward with reviewing PFAS treatment options and pilot testing to determine the best course of action if/when treatment is required.

The Town cannot manage sources like this indefinitely. They decided to move forward with reviewing PFAS treatment options and pilot testing to determine the best course of action if/when treatment is required.

Tata & Howard and the Town considered three treatment options. The first option is anion exchange, which uses a resin with positively charged ions. These are typically single use resins and require one to three minutes of empty bed contact time. The next option is Granular Activate Carbon (GAC) which uses adsorption. This media can be made from different types of carbon sources that can be recycled through thermal reactivations and requires a ten minute empty bed contact time. There are limitations with GAC on some of the short chain PFAS. The third type is novel media, which includes other types of media that do not fall into the first two categories. The novel media piloted uses an adsorption process that is classified as a single use resin and has a two to three minute empty bed contact time.

Shrewsbury’s pilot testing utilized three anion exchange resins from two suppliers (one of which was regenerative), a coal-based GAC, and a novel media. The novel media selected works like GAC since it is not as sensitive to chlorine and chlorides, which can impact the effectiveness of anion exchange resins.

The GAC pilot test utilized two 6-inch columns in series rather than one very tall column to give more flexibility for installation and backwashing. A total of 10 gallons of media were installed with a loading rate of 7.5 gal/ft2 and an empty bed contact time of approximately ten minutes. The anion exchange and novel medias each utilized one 6-inch column with five gallons of media installed, a loading rate of 11.25 gal/ft2, and an empty bed contact time of approximately two minutes.

The water source was a tap on the effluent line from the existing filters using finished water that had been treated for manganese removal but not any of the chemical additions of KOH, phosphate, chlorine, and fluoride. There were control valves so the water only came through the unit when the treatment plant was online, which is typically more than 20 hours per day.

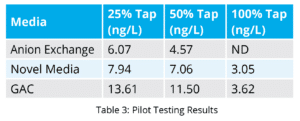

There was an initial baseline water quality sampling event at the start, at the end of week 20, and at the end of piloting. PFAS samples were taken day one, day seven, and then monthly for the duration of the pilot. Samples were taken from the 25% sample tap until breakthrough (50% of the raw water PFAS levels, so between 6 and 7 ppt), then at the 50% tap.

Table 3 shows the result from the different taps at the end of the pilot. The anion exchange results are from the best performing anion exchange resin. GAC was first detected in week 8 with breakthrough in the 25% tap in week 16 and the 50% tap in week 44. There was a detected amount in the final sample tap in week 64, which was the final week of the testing.

Table 3 shows the result from the different taps at the end of the pilot. The anion exchange results are from the best performing anion exchange resin. GAC was first detected in week 8 with breakthrough in the 25% tap in week 16 and the 50% tap in week 44. There was a detected amount in the final sample tap in week 64, which was the final week of the testing.

Anion exchange had the longest time to first detect but the 25% breakthrough for all anion exchange and novel media were all within a sample event or so of each other and occurred between weeks 44 and 52. The novel media had breakthrough of the 50% tap at week 60 and was detected in the 100% tap at the final week while the anion exchange was ND in the 100% tap at the end of the pilot.

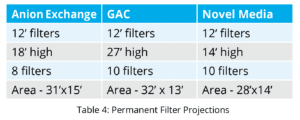

Table 4 is a summary as to what the permanent filter system may look like. The filters are similar in size but the number of recommended filters differs for each resin. The overall building footprint is similar as well. The anion exchange did perform slightly better than the novel media, however, the overall PFAS removal results over the duration of the pilot was similar. Because of this, construction costs, long term media replacement costs, and operational considerations were included as part of the media selection process.

Table 4 is a summary as to what the permanent filter system may look like. The filters are similar in size but the number of recommended filters differs for each resin. The overall building footprint is similar as well. The anion exchange did perform slightly better than the novel media, however, the overall PFAS removal results over the duration of the pilot was similar. Because of this, construction costs, long term media replacement costs, and operational considerations were included as part of the media selection process.

The Town has not yet made a final decision on media type, but it appears that the novel media may be the best fit for the Town’s needs. Specifically, the novel media allows for some backwashing and chlorination, reducing the potential of biofilm buildup and potential capacity loss due to increased headloss through the media. Additionally, the novel media has a smaller footprint in comparison to GAC. The Town of Shrewsbury’s current PFAS levels do contain mostly PFOS and PFOA at concentrations higher than the proposed Federal regulations for those two compounds. Also, based on reviewing the data of the PFAS6 compounds, PFOA was the compound first detected for all media; also, the majority of the detected PFAS6 concentrations in the effluent throughout the pilot were PFOA.

One additional challenge moving forward is the design of the facility so the water goes through the manganese treatment first, the new PFAS treatment next, and finally utilizes the existing clearwell for chlorine contact, with finished water pumping into the system, all while keeping the existing treatment online during construction and start up. Tata & Howard is currently completing a preliminary design to better estimate costs before completing the final design, permitting, and ultimately construction.