Stephen K. Rupar, P.E. a Vice President with Tata & Howard, formally passed the gavel of Chair to his successor at the 47th Annual Joint Meeting of the Connecticut Section of the American Water Works Association (CTAWWA) and the Connecticut Water Works Association (CWWA).

Jennifer K. Muir, P.E., President of JK Muir, accepted the position as Chair of the CT Section of the AWWA, during a ceremony held on May 23, 2018 at the Ocean Edge Resort & Golf Club located in Brewster, Massachusetts.

Approximately 80 guests working in water utility management, board and committee members from both organizations, and other industry professionals attended the three-day conference.

Every year, CTAWWA members and volunteers strive to improve public health and welfare by advancing the technology, science and governmental policies relative to the public drinking water industry’s role in the stewardship of water resources. In partnership with the CWWA, the Annual Joint Conference features technical sessions, legislative updates, national speakers, as well as enjoyable opportunities to network with colleagues and friends.

During Steve’s 8-year tenure as a Board member of the CTAWWA, he served two separate terms as Chair—in 2015-16 and most recently in 2017-18. “Working collectively, the Board solved some very difficult challenges facing the organization,” Steve said. “We corrected our budget deficits by improving the management of our finances. We also dealt with a common issue facing many of our members, retirement. We successfully replaced several long-serving volunteers and staff members, including two executive managers, two treasurers, and one secretary, all while maintaining and improving service to our members. In addition, with the help of many volunteers and board members, we worked long hours to advance the educational programming to keep our members informed on cutting-edge technology.”

A member of the AWWA since 1994, Steve will continue working with the Water Resources Committee and the Education and Program Committee at the CT Section of the AWWA. He will also be active on the Board in his new role as ‘Past Chair’. “Over the years, I have come to appreciate the incredible value this organization provides. I look forward to strengthening the technical and educational programming at the Annual Conference, guiding young professionals towards fulfilling careers in the water environment, and improving the quality of services to our members.”

The 2019 Annual Joint Meeting and Conference is currently planned for May 22-24 at a location to be named soon.

For more information about the Connecticut Section of the American Water Works Association visit: www.ctawwa.org

About the American Water Works Association

The American Water Works Association (AWWA) is an international nonprofit scientific and educational society dedicated to the improvement of drinking water quality and supply. Founded in 1881, AWWA is the largest and oldest organization of water supply professionals in the world. Its more than 50,000 individual members represent the full spectrum of the drinking water community: treatment plant operators and managers, scientists, environmentalists, manufacturers, academicians, regulators and others who hold a genuine interest in water supply and public health. Membership includes more than 4,000 utilities that supply water to roughly 180 million people in North America.

The Connecticut Section – AWWA is comprised of those members who live and/or do business within the state of Connecticut. The CT Section membership is about 700 strong and represents more than 60 utilities that supply water to approximately 2.5 million Connecticut residents.

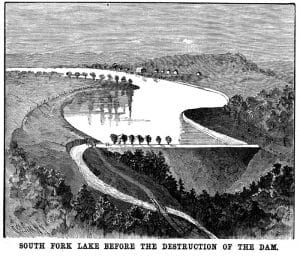

As the spring rains continued, life was about to change for the working-class city of 30,000 and other communities beneath the South Fork Dam.

As the spring rains continued, life was about to change for the working-class city of 30,000 and other communities beneath the South Fork Dam. For the pleasure of their private members, club owners soon began modifications to the dam. Fish screens were installed across the spillway to keep the expensive game fish from escaping. The dam was lowered by a few feet so that two carriages could navigate the carriage road to the clubhouse. Relief pipes and valves that controlled the water level and spill off from the original dam were sold off for scrap, and rustic cottages were built nearby.

For the pleasure of their private members, club owners soon began modifications to the dam. Fish screens were installed across the spillway to keep the expensive game fish from escaping. The dam was lowered by a few feet so that two carriages could navigate the carriage road to the clubhouse. Relief pipes and valves that controlled the water level and spill off from the original dam were sold off for scrap, and rustic cottages were built nearby. Club officials struggled to reinforce the earthen dam, but it continued to disintegrate. When the lake’s water began to pour over the top, it was apparent that a catastrophic collapse was inevitable and imminent. Frantic riders were sent down the valley to alert the local communities and tell them to evacuate. Sadly, few residents heeded the alarm being so often used to the minor seasonal flooding from the Little Conemaugh river.

Club officials struggled to reinforce the earthen dam, but it continued to disintegrate. When the lake’s water began to pour over the top, it was apparent that a catastrophic collapse was inevitable and imminent. Frantic riders were sent down the valley to alert the local communities and tell them to evacuate. Sadly, few residents heeded the alarm being so often used to the minor seasonal flooding from the Little Conemaugh river. Along the way, the deluge accumulated everything in its path, including all sorts of debris—from city buildings, houses, and barns. Piles of boulders, trees, farm equipment, rolls of barbed wire, horse carriages, and railroad cars churned in the turmoil. Embroiled in the devastation were also animals and people—both dead and alive.

Along the way, the deluge accumulated everything in its path, including all sorts of debris—from city buildings, houses, and barns. Piles of boulders, trees, farm equipment, rolls of barbed wire, horse carriages, and railroad cars churned in the turmoil. Embroiled in the devastation were also animals and people—both dead and alive. It would take months to sift through all the wreckage to find the bodies and years to fully recover from the aftermath.

It would take months to sift through all the wreckage to find the bodies and years to fully recover from the aftermath. A hydraulic analysis published in 2016 confirmed what had long been suspected, that the changes made to the dam by the South Fork Fishing and Hunting Club severely reduced the ability of the dam to withstand major storms.1

A hydraulic analysis published in 2016 confirmed what had long been suspected, that the changes made to the dam by the South Fork Fishing and Hunting Club severely reduced the ability of the dam to withstand major storms.1