As of August 7, 2017, MassDEP’s closure requirement 310 CMR 80.15 mandates all single-walled steel underground storage tanks (USTs) to be closed-in-place or removed. Covered under this regulation are tanks and associated piping that have more than ten percent of their volume underground and hold petroleum products or hazardous substances listed in the U.S. Comprehensive Environmental Response Compensation Liability Act. With the deadline now less than one year away, it is important to fully understand single-walled USTs, their potentially harmful impact on the environment, and how to properly plan to remove them.

Single-Walled USTs Explained

USTs have been used for many years to store hazardous substances and petroleum products used by a wide variety of businesses. In addition to the tank itself, a “UST system” includes the underground piping that is used to fill the tank and draw product from it. Until the mid-1980s, most USTs were made of bare steel, which is likely to corrode and leak over time. These leaks can exist undetected for years and cause pollution of the surrounding soil and even groundwater. The piping in the system can also leak if not properly installed and maintained. In many cases, contaminant leaks do not get discovered until the owner or operator realizes that a significant amount of product in a tank goes missing or when the tank is removed and contaminants are found in the underlying soil. Another indication of a leaking UST is neighbors complaining of odors in their buildings or experiencing problems with their drinking water.

Leaking USTs, specifically single-walled steel USTs, have caused considerable environmental damage in Massachusetts, affecting public and private water supplies, wetlands, and soil. In some cases, vapors from contaminated soil and water have permeated homes and businesses. Many millions of dollars have already been spent on cleaning up these leaks, but fully protecting public health and the environment from UST leaks relies on removing or closing the storage tanks altogether.

Benefits of the MassDEP UST Removal Requirements

The removal or permanent closure of aging, single-walled USTs benefits many areas of a community. The new MassDEP regulations will benefit human health, ecosystem functions, and land productivity.

Human health benefits are among the top reasons why single-walled USTs are now required to be removed by August 7, 2017. Contaminated well water and vapor intrusion are the most critical threats to human health from failing USTs. Leaks from USTs can endanger residents for miles through contamination of groundwater, and increased cancer rates and blood disorders have been attributed to exposure to petroleum products, which are commonly found in USTs. The petroleum vapors which are emitted are highly flammable and are potentially dangerous when found in people’s homes. Vapors can travel through soil, sewer lines, storm drainage systems, and other pathways to enter homes and other buildings.

Many single-walled USTs are located in old gas stations, providing the opportunity to add aesthetic and ecological benefits to a community. If a UST leaks into soil, the site becomes contaminated and is considered a brownfield. Removing or closing USTs and making the site usable again decreases the need for development elsewhere and helps preserve greenfields, such as pastures or forests. Many old gas stations are situated in quite visible locations within towns or neighborhoods and can be reused for purposes such as gateways, town centers, or pocket parks. Such redevelopment opportunities improve a locality’s appeal and create recreational value.

Removing or closing-in-place single-walled USTs results in several ecological benefits. Preventing leakage of hazardous material can reduce surface water contamination – protecting fish and other wildlife. Below the ground, removing USTs ensures that leaking tanks will not compromise underground aquifers for future generations. In the long run, this will better protect our drinking water’s taste and purity. Removing USTs also greatly improves land use because former UST sites with a “clean bill of health” will be more likely to develop and prosper without environmental restrictions.

Are there any exceptions to the new regulations?

The MassDEP has included exceptions to the UST removal regulations. Tanks are not required to be removed or closed-in-place if they are consumptive use tanks – such as for heating oil in homes – and single-walled tanks that were relined prior to August 8, 2007 in accordance with API 1631. For these relined tanks to be exempt, the owner or operator must possess a permit and approval issued by the head of the local fire department, or a current legally valid warranty for relining. Other exceptions to the new regulations include single-walled steel tanks that have been wrapped with fiberglass, aramid, carbon fiber, or plastic compounds. It is important to note that single-walled steel tanks that are temporarily out-of-service are NOT exempt from the closure requirement, even if they are consumptive tanks for onsite usage. USTs that are not actively used or temporarily out of service are considered abandoned and must be removed or closed-in-place by August 7, 2017.

MassDEP’s UST closure regulation allows tanks to be permanently closed-in-place only if they cannot be removed from the ground without removing a building, or the removal would endanger the structural integrity of another UST, structure, underground piping, or underground utilities. When closing a tank in place, it is required to clean all contaminants out of the tank to prevent future leaks.

In Conclusion

Meeting MassDEP’s closure requirements means more than just being up to code. Removing hazardous USTs benefits everyone involved. It improves a property’s environmental footprint, removes high risk conditions, and reduces an owner’s environmental liability. Compared to the cost of cleaning up hazardous materials after a UST leak, removing a single-walled UST is well worth it. There is only one year left to comply with the MassDEP UST regulations, so it is imperative to start planning now to remove or close-in-place your single-walled USTs.

Please feel free to contact us for any questions on MassDEP’s requirement or for assistance with UST removals and closures.

In honor of International Beer Day, we are taking a look at what breweries are doing to conserve the number one ingredient in brewing beer: water. Due to water shortages, increased demand, and heightened awareness, many breweries have taken steps to increase water efficiency and to implement water saving techniques in their brewing. Utilizing a myriad of methodologies and technologies, an increasing number of today’s breweries have begun to focus on brewing beer with water efficiency and conservation at the forefront of their business.

In honor of International Beer Day, we are taking a look at what breweries are doing to conserve the number one ingredient in brewing beer: water. Due to water shortages, increased demand, and heightened awareness, many breweries have taken steps to increase water efficiency and to implement water saving techniques in their brewing. Utilizing a myriad of methodologies and technologies, an increasing number of today’s breweries have begun to focus on brewing beer with water efficiency and conservation at the forefront of their business. The undisputed behemoth of the beer world with 25% of the global beer market, Anheuser-Busch InBev has implemented water-saving measures in many ways. Some of its plants use reclaimed water for equipment cleaning, irrigation, firefighting, and other local uses, such as watering a soccer field in Peru and manufacturing bricks in Brazil. And, as would be expected from such an enormous, influential company, Anheuser-Busch InBev is piloting agricultural programs that it hopes will spread to all facets of agriculture. To start, they have initiated a “Smart Barley” program with 2,000 barley growers in Idaho and Montana. Since agriculture accounts for 95% of the water used in beer making, increasing agricultural water efficiency is the key to breweries becoming better water stewards. Utilizing sensors in the field, cooperative programs, and its own hybridized, drought-resistant seeds, Anheuser-Busch InBev hopes to decrease agricultural water usage by 25% over the next two years.

The undisputed behemoth of the beer world with 25% of the global beer market, Anheuser-Busch InBev has implemented water-saving measures in many ways. Some of its plants use reclaimed water for equipment cleaning, irrigation, firefighting, and other local uses, such as watering a soccer field in Peru and manufacturing bricks in Brazil. And, as would be expected from such an enormous, influential company, Anheuser-Busch InBev is piloting agricultural programs that it hopes will spread to all facets of agriculture. To start, they have initiated a “Smart Barley” program with 2,000 barley growers in Idaho and Montana. Since agriculture accounts for 95% of the water used in beer making, increasing agricultural water efficiency is the key to breweries becoming better water stewards. Utilizing sensors in the field, cooperative programs, and its own hybridized, drought-resistant seeds, Anheuser-Busch InBev hopes to decrease agricultural water usage by 25% over the next two years.

Oregon-based

Oregon-based

distribution systems. Water audits are a vital step toward reducing lost water while improving water infrastructure. We lose billions of dollars every year to NRW — money that could be used to improve our infrastructure or to support other clean water initiatives. Water lost is water and money wasted, and the less NRW a utility has, the better off it — and its customers — will be.

distribution systems. Water audits are a vital step toward reducing lost water while improving water infrastructure. We lose billions of dollars every year to NRW — money that could be used to improve our infrastructure or to support other clean water initiatives. Water lost is water and money wasted, and the less NRW a utility has, the better off it — and its customers — will be.

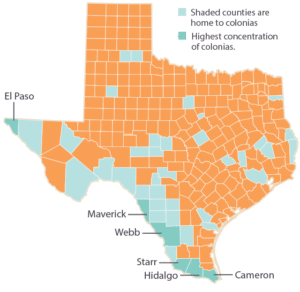

Recently in the news, we have heard a lot about the nationwide

Recently in the news, we have heard a lot about the nationwide

Fortunately, Texas passed the Colonias Fair Land Sales Act in 1995 to somewhat protect colonia residents who are forced to finance through a contract for deed. The Act requires developers to record the contract with the county clerk and to provide property owners with an annual statement that shows the amount paid towards the loan and taxes as well as the number of remaining payments. The Act also forces developers to itemize which services, such as water, wastewater, and electricity, are available, and whether the land is located in a flood plain.

Fortunately, Texas passed the Colonias Fair Land Sales Act in 1995 to somewhat protect colonia residents who are forced to finance through a contract for deed. The Act requires developers to record the contract with the county clerk and to provide property owners with an annual statement that shows the amount paid towards the loan and taxes as well as the number of remaining payments. The Act also forces developers to itemize which services, such as water, wastewater, and electricity, are available, and whether the land is located in a flood plain.

Part three of our four-part series on water crises in America is on lead contamination. Instances of lead in drinking water, such as the situation in Flint, Michigan, have become a hot topic in the media. Lead in drinking water is a problem that reaches far beyond the disaster in Flint, with the Environmental Protection Agency (EPA) stating that roughly 10 million American homes and buildings still receive water from service lines that are at least partially lead. When water has high acidity or low mineral content, it can cause these service lines to corrode and leach lead into the water supply. Without mitigation, water from lead service lines has the potential to cause adverse health effects,

Part three of our four-part series on water crises in America is on lead contamination. Instances of lead in drinking water, such as the situation in Flint, Michigan, have become a hot topic in the media. Lead in drinking water is a problem that reaches far beyond the disaster in Flint, with the Environmental Protection Agency (EPA) stating that roughly 10 million American homes and buildings still receive water from service lines that are at least partially lead. When water has high acidity or low mineral content, it can cause these service lines to corrode and leach lead into the water supply. Without mitigation, water from lead service lines has the potential to cause adverse health effects,