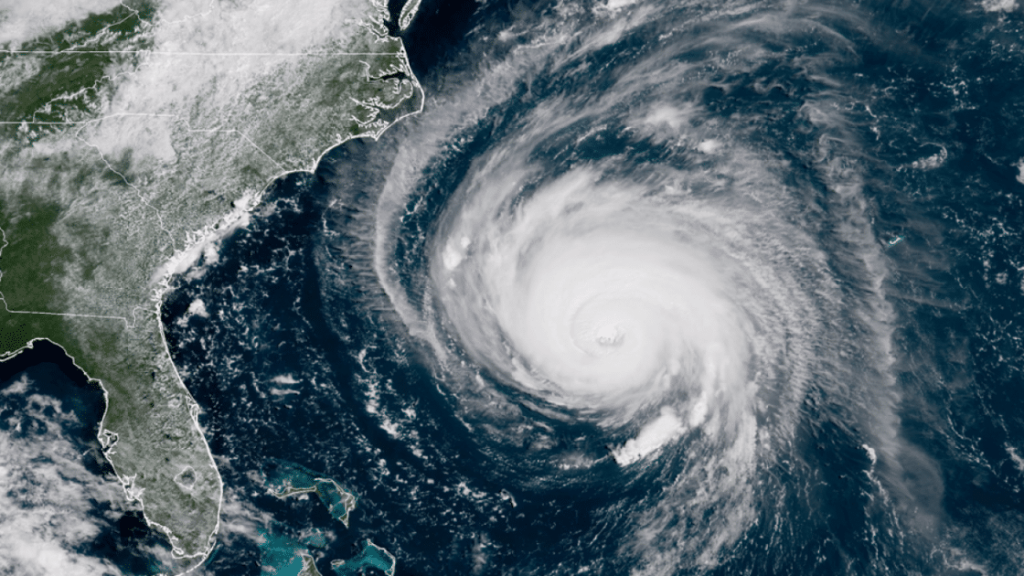

As of June 1, hurricane season is in full effect through November 30. Areas along the Atlantic Coast, Gulf of Mexico, and the Hawaiian Islands are most vulnerable to hurricanes. As inhabitants within each of these areas take caution each year, it is equally important that water utilities do the same and become hurricane ready.

Due to heavy rainfall, inland flooding, and high winds of 74 mph or greater, hurricanes have the potential to cause serious damage to water and wastewater utilities. Some examples of the detrimental nature of hurricanes on water utilities include:

- Pipe breaks that could lead to sewage spills or low water pressure throughout service areas

- Loss of power and communication infrastructure

- Combined sewer overflows (CSO)

- Restricted access to facilities and collection/distribution system assets

- Loss of water quality testing capability

The Environmental Protection Agency (EPA) has developed tools to help water utilities prepare for, respond to, and recover from hurricane related impacts.

Preparing for Hurricane Season

Planning

- Be sure your utility’s Emergency Response Plan (ERP) is up-to-date, and ensure all emergency contacts are current

- Be sure utility staff is aware of all preparedness procedures by conducting trainings and exercises

- Identify high-priority customers (such as hospitals), map their locations, and obtain contact information in the event of an emergency

- Develop an emergency drinking water supply plan that may include bulk water hauling, mobile treatment units or temporary supply lines

- Review historical records to understand the frequency and intensity of past hurricanes and how the utility may have been affected

- In the event that you need to apply for federal disaster funding, complete pre-disaster activities. For example, taking photos of the facility to compare with post-damage photos

Coordination

- Join your state’s Water/Wastewater Agency Response Network (WARN)

- Get in touch with WARN members and other utilities to discuss ways in which help can be provided if needed. This includes outlining response activities and responsibilities; conducting full-scale exercises; obtaining resources and assistance; establishing interconnections between systems; establishing communication protocols to reduce misunderstandings

- Coordinate with other key response partners, including your local EMA, to discuss potential points of distribution for the delivery of emergency water supply

- Understand what your utility may be called on to do, as well as how local emergency responders and the local emergency operations center (EOC) can support your utility

Communication with Customers

- Provide customers with materials that contain information on what they will need during a hurricane (i.e. information on water advisories and instructions for private well and septic system maintenance)

- Distribute public information protocols with customers prior to a known storm (i.e. warnings that service disruptions are likely)

Facility and Service Area

- Be sure to order and inventory existing equipment and supplies including:

- Motors

- Fuses

- A two-week supply of chemicals

- Cell phones and other wireless communication devices

- Tarps/tapes/rope

- Cots/blankets

- First-aid kits

- Foul weather gear

- Flashlights/flares

- Plywood

- Sandbags

- Bottled water

- Batteries

- Non-perishable food

- Ensure that radios and satellite phones are working and fully charged

- Develop a GIS map of all system components

- Document pumping requirements, storage capabilities, and critical treatment components and parameters

Power, Energy and Fuel

- Work with local power utilities to assure tree branches near power lines are trimmed

- Inspect conditions, connections and switches of electrical panels

- Document power requirements of the facility

- Test generators regularly

- Inform fuel vendors of estimated fuel volumes needed if utility is impacted

- Reach out to local power providers to assure that your water utility is on the critical facilities list for priority electrical power restoration

Responding to a Hurricane – Pre-landfall Activities

Planning

- Actively monitor hurricane activity

Facility and Service Area

- Move equipment to water-tight facilities or out of flood-prone areas

- Clear storm drains and set up sandbags to protect facilities

- Be sure that back-up equipment and facility systems including controls and pumps are in worker order

- Protect exposed lines or pipes that may be vulnerable during a storm

- Fill storage tanks to full capacity and fill empty chemical storage tanks with water

- Wastewater utilities should empty holding tanks, ponds and/or lagoons to prepare for an increase in flow

Personnel

- Identify essential personnel and ensure they are trained to perform critical duties in an emergency

- Establish communication procedures with both essential and non-essential personnel

- Identify emergency operations and clean-up crews

- Establish alternative transportation strategies if roads become impassable

- Understand how limited staffing will impact response procedures if there are transportation issues or evacuations

Power, Energy and Fuel

- Make sure vehicles and fuel tanks are filled to full capacity and ensure you can manually pump gas in the event of a power outage

Responding to a Hurricane – Post-landfall Activities

Coordination

- Notify your local EMA and state regulatory agency of system status

- Request or offer assistance through mutual aid networks, such as WARN, if needed

- Assign a representative of the utility to the incident command post

Communication with Customers

- Notify customers of any water advisories and coordinate with local media to distribute the message

Facility and Service Area

Overall

- Assess the damage of the utility to prioritize repairs

- Assure that back-up equipment and facility systems, such as controls and pumps, are in working order, and ensure that chemical containers and feeders are intact

Drinking Water Utilities

- Inspect the utility and service area for damage

- Ensure pressure is maintained throughout the system and isolate the sections where it is not

- Control and isolate leaks in water transmission and distribution piping

- Shut off water meters at destroyed properties

- Monitor water quality

- Notify regulatory agency if operations and/or water quality or quantity are affected

- Utilize the pre-established emergency connections or create temporary connections to nearby communities as needed

- If needed, implement plans to draw emergency water from pre-determined tanks or hydrants

Wastewater Utilities

- Inspect the utility and service area for damage

- Inspect the manholes and pipelines in flood-prone areas for inflow and infiltration after water recedes

- Suspend solid waste processing during periods of high flow to conserve bacteria and prevent it from washing out of the plant

- Notify regulatory agency of any changes to the operations or required testing parameters

Documentation and Reporting

- Document damage assessments, mutual aid requests, emergency repair work, equipment used, purchases made, staff hours worked, and contractors used to have open hand when applying for federal disaster funds

- Work with local EMA on the required paperwork for public assistance requests

Personnel

- Account for all personnel and provide emergency care, if needed

- Deploy emergency operations and clean-up crews

Power, Energy and Fuel

- Use back-up generators as needed

- Plan for additional fuel needs in advance and coordinate fuel deliveries to generators

- Stay in close contact with electric provider for power outage duration estimates

Recovering from a Hurricane

Coordination

- Work with response partners to obtain equipment, funding, etc.

Communication with Customers

- Be sure a utility representative is communicating with customers in reference to a timeline for recovery

Facility and Service Area

- Complete damage assessments

- Complete repairs, replace depleted supplies and return to normal service

Documenting and Reporting

- Compile damage assessment forms and cost documentation into a single report to share, in addition to, state and federal funding applications

- Create a ‘lessons learned’ document and/or after action report (AAR) to keep record of response activities

- Revise budget and asset management plans

Mitigation

- Identify mitigation and long-term adaptation measures that can prevent damage and increase utility resistance. Examples of successful mitigation projects by water and wastewater utilities include:

- Providing protection to electrical substation and transformers that would be in danger of failing during floods, high winds and storm surges

- Retrofitting sanitary sewer lift stations with electrical connections for portable generators

- Elevating generators, fuel tanks and critical controls to protect from coastal storm surges

- Replacing existing entry doors with heavy-duty impact-resistant doors

For more information on how to prepare for and respond to hurricane impacts and for a printable checklist to utilize within your water or wastewater utility, please visit the EPA’s site here.