by Justine Carroll, Vice President, Tata & Howard, Inc., October, 2022

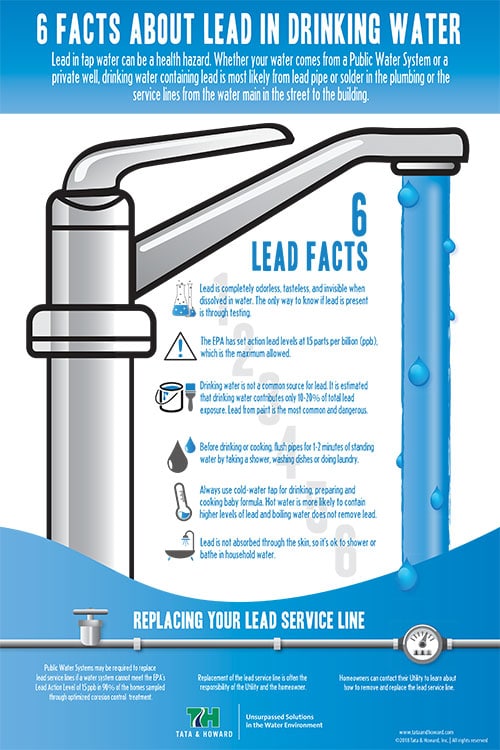

For the first time since the formation of the Environmental Protection Agency (EPA), the agency has mandated all municipalities, under section §141.84 of the Lead and Copper Rule Revision (LCRR), to develop and submit for review a lead service line (LSL) inventory plan including both public and private side. Municipalities’ inventories servicing 50,000+ populations must be available on the municipality’s website, allowing residents and business owners to access information online to determine if the line on public or private land contains lead. The EPA administration is encouraging early plan submissions allowing review and revision time to meet the October 16, 2024, deadline.

The following planning structure serves as a guideline for an LSL inventory plan. The shared information provided is not all-encompassing, allowing individual municipalities to customize their inventory plan to their needs.

Start preparing an LSL Inventory

Find and organize internal data such as metered accounts, assessors’ data, record files, service cards, building permit records, work orders, and field excavations. Create a customer survey using mailings or mobile applications to help identify LSL materials for homes or businesses. Develop public education programs to notify private owners and residents through invoicing, email, and notices.

Structuring the database – Categories, Subcategories, and Service Indicators

The next step in developing an LSL plan is to assign categories and subcategories to identify and report quickly. Data fields can include sampling locations, connection material, current and past service line material, installation date, classification, building type, building installation year, plumbing material, and service line replacement status. Template spreadsheets are available at the state level; using them allows for universal fields and drop-down menus for continuous data input.

The inventory will identify services with service lines categorized as lead, galvanized requiring replacement, or lead status unknown; consider installation and home construction dates, service line size, and water-main installation year when actual dates are unavailable.

Base your starting point with the 1986 EPA Lead Ban and local ordinances to determine when lead installations were not allowed in the public water system. Services with unknown materials should be ranked for verification by indicating high priority of lead, medium priority of lead, or low priority of lead.

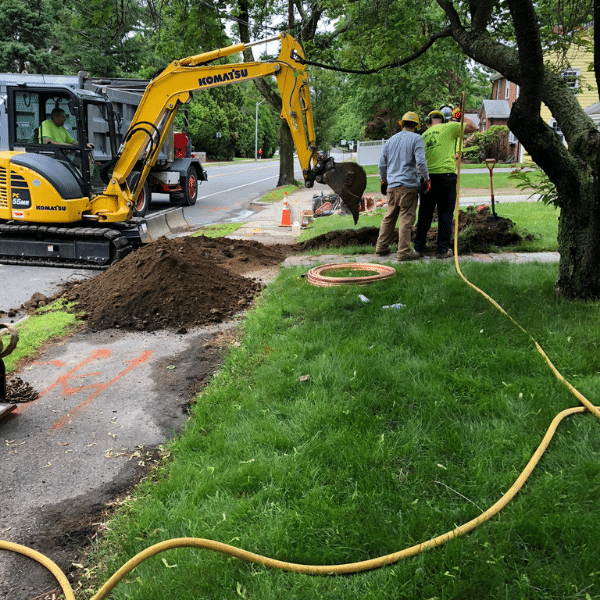

Create a public LSL replacement program to eliminate known lead service lines and work with private owners to replace necessary lines; often, monetary incentivized programs are available. Next, develop a verification process consisting of customer surveys, home inspections, water quality sampling, or mechanical excavation.

Lastly, internally link the database to a shapefile in your GIS or other mapping software to identify service line materials quickly; data can be made public for communities with more than 50,000 people.

To contact Justine M. Carroll, Vice President, Tata & Howard, Inc.

jcarroll@tataandhoward.com | Direct ((508) 219-4018

Let’s Connect on LinkedIn