Tata & Howard provided engineering services to the City of Westfield for its water tanks, most recently the Provin Tank. For background, the City of Westfield water system consists of 242 miles of water main ranging in size from under 4-inches up to 24-inches and has one main service area. There are also four small high service areas, each of which utilizes a booster pump station. There are nine groundwater supply sources and one active surface water supply source, the Granville Reservoir, and there are interconnections with the City of Springfield at three locations. The system has a total of four tanks with a total capacity of 11.2 million gallons (mg). In 2014, a Condition Assessment Report was completed for each of the City’s four prestressed concrete tanks in order to evaluate condition of each tank and provide recommendations for required rehab work.

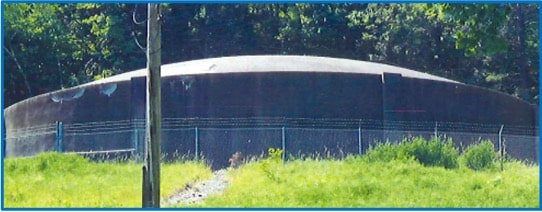

The site of the East Mountain Tank, a 2.7 mg tank constructed in 1961, was deemed a “hard hat zone” due to its declining condition. The dome and dome cap were determined to be in fair to poor condition, showing significant deterioration of concrete, and it was further determined that the dome would need to be completely replaced. Due to the significant rehabilitation required, the City decided to construct a new tank. Tata & Howard started the design of the new East Mountain Road Tank in 2017, and the new tank was constructed and operative by 2020.

Wanting to be proactive and avoid the deterioration found at the old East Mountain Road Tank, the City contracted Tata & Howard in 2020 to design and bid the rehab of the City’s three other tanks: the Northwest Road Tank, Sackett Tank, and Provin Mountain Tank.

Rehab work required on the Northwest Road Tank, which was constructed in 1975, consisted of exterior cleaning and coating, repairing of concrete patches, replacing access hatches, replacing the dome vent, and installation of a new overflow screen.

The Sackett Tank, which was more recently constructed in 1991, only required exterior cleaning and coating and replacement of an access hatch.

The Provin Mountain Tank, which is located in the southeastern corner of City, is a 5.0 mg prestressed concrete tank originally constructed in 1967. Measuring 148 feet in diameter and standing 40 feet high, it connects to the system via a 16-inch line. The original scope of the rehab work needed was as follows:

- Exterior cleaning and coating

- Concrete patch repairs

- Injecting a polyurethane grout into a crack

- Replace dome hatch and dome vent

- Install new overflow screen

- Evaluate and repair exposed and broken prestressed wires

With all of these tanks being prestressed concrete, prestressed wires are wrapped tightly around the dome ring as reinforcement to hold the weight of the water. In October 2021, the contractor arrived on site to complete the rehab work on the Provin Mountain Tank. When they started chipping away at loose concrete, it was discovered just how bad the condition of the dome ring was. Each day, more wires were found broken, with more than one third of the total wires found to be broken. The dome was in danger of potential collapse.

The team reconvened to discuss next steps on the project. During rehab work, the contractor surveyed the surrounding area to see if any residents were potentially in the path of the tank if it were to collapse. The tank level was lowered to about 25% capacity, and it was decided to complete repairs on the tank to act as a temporary fix. Temporary repair work began in October 2021 and was completed in April 2022, consisting of the following:

- Remove all loose gunite material and broken wire by hand

- Apply shotcrete to the dome ring face and provide a uniform surface

- Install prestressing strand, Teflon shims, and anchors

- Apply shotcrete to fully encapsulate the prestressing strand

- Repeat for subsequent layers (estimate 3-4 layers, 17 strands total, 0.6 inch each)

- Pressure-wash top surface and face of dome ring

- Seal surface cracks on the top surface of the dome ring with Sika 55

- Apply a waterproof coating on the dome ring apron and face (Tamoseal)

This repair work extended the useful life of the tank by 2-5 years. The question then was whether to abandon the existing tank or replace it with a new tank. To evaluate if a replacement tank was needed, a storage evaluation was completed. US Census trends and ASR data used to estimate service populations and demands to 2041 showed that the future MDD was estimated at 10.7 mgd. Emergency storage, equalization storage, and fire flow storage were calculated and totaled for current and future demand conditions, showing that the future required storage for the system was approximately 2.77 mg. While having a water storage surplus may initially sound like a positive, too much of a surplus can lead to water quality issues such as water age and disinfection byproducts. This data indicated a replacement tank was not needed based on needed system storage alone.

Hydraulic impact was also studied. Pressure decreased 2-4 PSI depending on which sources were running, and the available fire flow decreased up to 600 gpm, but was limited to the area around the tank which is mostly residential. Resultant flows were sufficient for the residential area.

Hydraulic impact was also studied. Pressure decreased 2-4 PSI depending on which sources were running, and the available fire flow decreased up to 600 gpm, but was limited to the area around the tank which is mostly residential. Resultant flows were sufficient for the residential area.

While storage and hydraulics showed that the tank was not needed, it was determined that there would be significant lack of fire protection in much of the system if the Sackett Tank was offline for repairs or other issues in addition to elimination of the Provin Mountain Tank. Due to the lack of fire protection under this scenario, it was ultimately recommended to replace the tank.

While storage and hydraulics showed that the tank was not needed, it was determined that there would be significant lack of fire protection in much of the system if the Sackett Tank was offline for repairs or other issues in addition to elimination of the Provin Mountain Tank. Due to the lack of fire protection under this scenario, it was ultimately recommended to replace the tank.

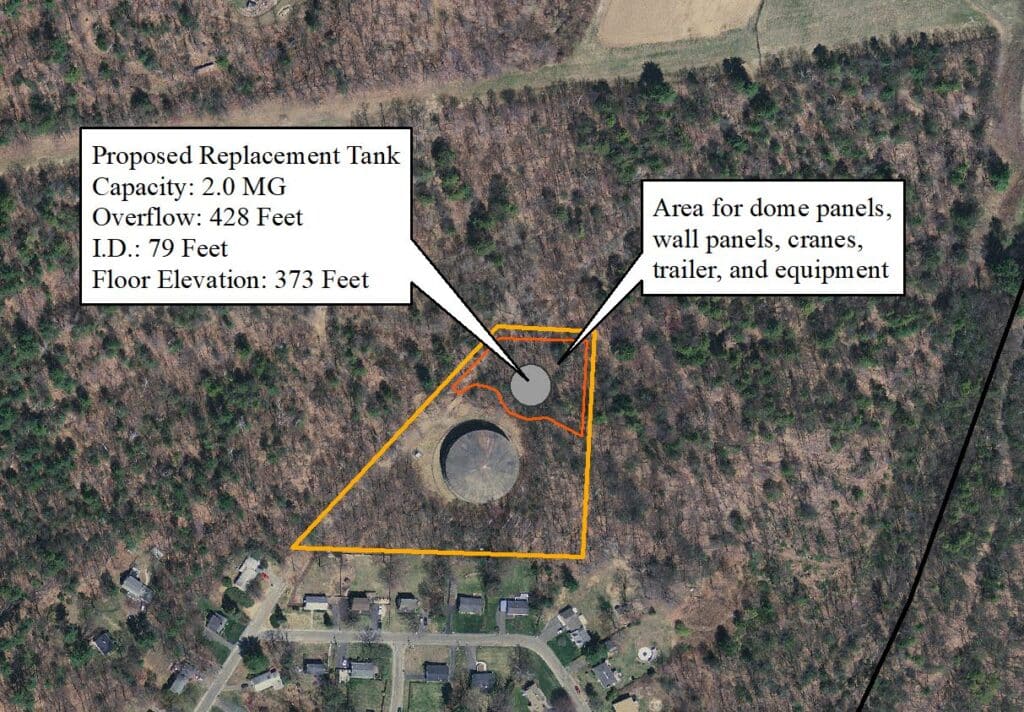

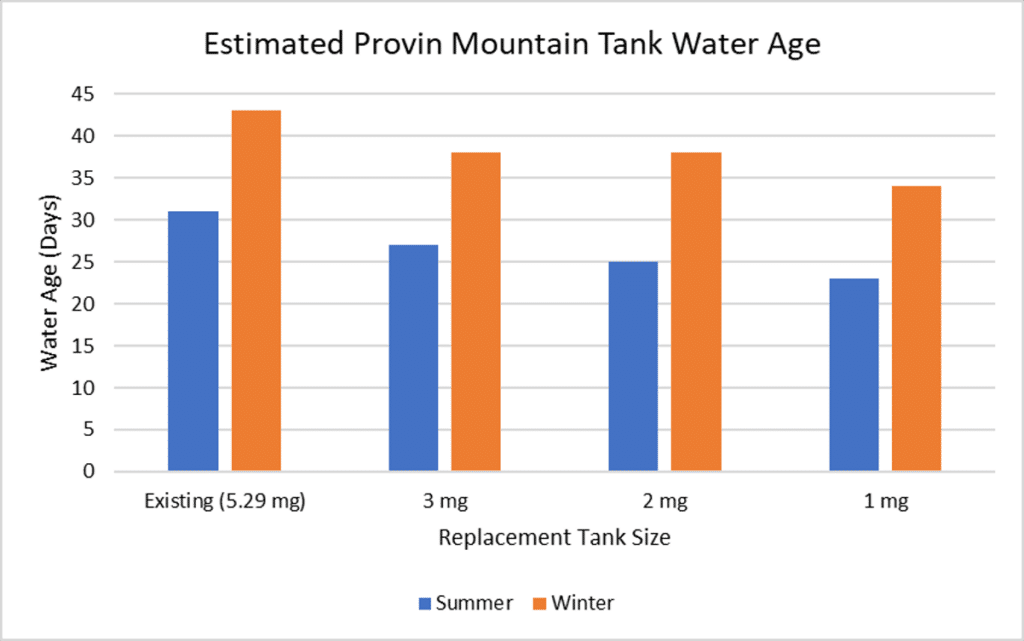

EPS modeling was used to evaluate change in water age for various size replacements. It was ultimately decided to construct a 2 mg tank with the recommendation that the City change the operation of their wells to increase fluctuation in tank levels. Overflow was decided to match the old tank at 428 feet, and the inside diameter of the new tank would be 79 feet compared to 148 feet of the existing tank. The new Provin Tank is currently in design with an anticipated bid this fall, with site work expected to begin by late fall. Given that temporary repairs were completed in April 2022, we are on track to replace the tank within the 2-3 year time frame based on the lifespan of the temporary repairs.

The existing tank will be demolished after the new tank is in service.

During the course of the design, it was determined that the backwash water would not be permitted by the MWRA to be discharged into the sewer system. Therefore, alternatives needed to be evaluated. One option was to provide holding tanks for the backwash water. This would enable the Town to recycle the supernatant to the head of the facility and therefore, minimize waste of the supply water. Since the area was not conducive for the installation of drying beds, the sludge collected at the bottom of the holding tank was removed by means of a septage hauler.

During the course of the design, it was determined that the backwash water would not be permitted by the MWRA to be discharged into the sewer system. Therefore, alternatives needed to be evaluated. One option was to provide holding tanks for the backwash water. This would enable the Town to recycle the supernatant to the head of the facility and therefore, minimize waste of the supply water. Since the area was not conducive for the installation of drying beds, the sludge collected at the bottom of the holding tank was removed by means of a septage hauler. Tata & Howard contracted with the Town of Amherst for design, permitting, and bidding of the 1.5 million gallon per day (MGD) Centennial Water Treatment Plant, to treat surface water from the Pelham Reservoir System. The existing Centennial WTP, located in the Town of Pelham but supplying the Amherst Public Water System, has a history of issues with turbidity, color, and disinfection byproducts in the form of total trihalomethanes (TTHM) and haloacetic acids (HAA5) because of high levels of organics in the Pelham Reservoir System. Due to the age and condition of the existing WTP, the filters which were the primary treatment process at the existing WTP were no longer effective at removing organics, leading to a decrease in finished water quality and total WTP capacity. The existing Centennial WTP has been offline since 2018 due to water quality, as well as infrastructure concerns related to a lightning strike which impacted pumping equipment and communications at the Centennial Water Treatment Plant’s raw water pump station.

Tata & Howard contracted with the Town of Amherst for design, permitting, and bidding of the 1.5 million gallon per day (MGD) Centennial Water Treatment Plant, to treat surface water from the Pelham Reservoir System. The existing Centennial WTP, located in the Town of Pelham but supplying the Amherst Public Water System, has a history of issues with turbidity, color, and disinfection byproducts in the form of total trihalomethanes (TTHM) and haloacetic acids (HAA5) because of high levels of organics in the Pelham Reservoir System. Due to the age and condition of the existing WTP, the filters which were the primary treatment process at the existing WTP were no longer effective at removing organics, leading to a decrease in finished water quality and total WTP capacity. The existing Centennial WTP has been offline since 2018 due to water quality, as well as infrastructure concerns related to a lightning strike which impacted pumping equipment and communications at the Centennial Water Treatment Plant’s raw water pump station.