Municipal wastewater treatment requires an enormous amount of energy, which comes at a high cost, both fiscally and environmentally. Energy costs continue to rise while municipal budgets shrink, creating unsustainable operating costs. Indeed, energy efficiency for wastewater utilities is no longer a choice, but a necessity. The good news is that there are many relatively inexpensive and easily implemented ways of controlling energy costs at wastewater treatment facilities, and the payback period can easily justify the investment.

The first step towards making an informed decision about energy efficiency at a wastewater treatment facility is an energy audit. A quality wastewater energy audit takes into account energy efficient equipment replacement, operational changes, and process control, and includes conducting on-site observations, testing wastewater systems and equipment, and monitoring power costs and usage. The result of a well executed energy audit is a justifiable plan of action that provides optimal energy savings, a true road map to energy efficiency.

The first step towards making an informed decision about energy efficiency at a wastewater treatment facility is an energy audit. A quality wastewater energy audit takes into account energy efficient equipment replacement, operational changes, and process control, and includes conducting on-site observations, testing wastewater systems and equipment, and monitoring power costs and usage. The result of a well executed energy audit is a justifiable plan of action that provides optimal energy savings, a true road map to energy efficiency.

Once the audit results are in, a number of changes, both large and small, can be made to save on energy costs. Wastewater treatment plants can conserve energy in many ways, from changing light bulbs and upgrading motors to installing combined heat and power systems and other renewable energy technologies. Some energy efficient options are highlighted below:

Equipment & Collection System Upgrades

Variable-Frequency Drives

Variable-frequency drives (VFDs) modify the speed of electric motors by adjusting the amount of power being delivered. These precise drives adjust motor speed to match the exact energy demand needed at any given time. By controlling the amount of power used, VFDs provide significant cost savings to wastewater treatment facilities and to the environment. A good application for VFDs is the blowers on the aeration system. Dissolved oxygen probes installed in the aeration basin can provide real time measurement of oxygen concentration in the wastewater. This information can be sent to the VFDs to speed up or slow down the blowers to provide only the oxygen needed for the biological process to thrive. The result — significant savings and happy microbes.

Heating, Cooling, and Ventilation Systems

Heating, Cooling, and Ventilation Systems

Updated HVAC systems that incorporate energy-efficient technologies provide operational savings and reduce energy consumption. Like VFDs, the most cost-effective time to upgrade these systems is when they are already due for replacement.

Energy Efficient Lighting

Installing energy efficient lights and lighting systems is one of the easiest ways to increase energy efficiency at wastewater utilities. Replacing burnt-out lights with fluorescents or LEDs eases into the transition and makes it affordable. Dimmers, motion sensors, and time switches can be installed to save even more energy — and money.

Operating Strategies

Electrical Load Management

Strategies such as improving the power factors of motors, reducing peak demand, and shifting to off-peak hours all provide significant savings for wastewater treatment facilities.

Biosolids Management

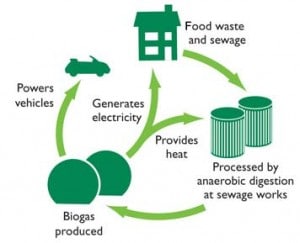

Biosolids, or the solid organic matter that is a by-product of the wastewater treatment process, should be managed sustainably in order to reduce both environmental and economic costs. Sustainable biosolids management incorporates efficient methods of treatment, transport, and end-use. By implementing a sustainable biosolids management plan, such as pretreatment for minimizing sludge treatment and recycling/reuse of residual sludge, municipalities can reduce greenhouse gases as well as trucking miles, thereby saving money and generating energy.

Operational Management

While updating equipment is a great way to increase energy efficiency, even more important is training managers and staff to think and operate efficiently. Educating wastewater utilities’ staff on the importance of energy conservation and on best practices yields significant savings for wastewater utilities and the environment.

While updating equipment is a great way to increase energy efficiency, even more important is training managers and staff to think and operate efficiently. Educating wastewater utilities’ staff on the importance of energy conservation and on best practices yields significant savings for wastewater utilities and the environment.

Inflow and Infiltration Management

Inflow and infiltration (I/I) in a wastewater facility’s collection system results in significantly higher costs to utilities. Increased flow requires additional processing, and results in higher demand to lift station pumps. In addition, systems are at an increased risk of becoming overloaded. Controlling I/I is a key step to becoming a more efficient wastewater treatment facility.

Energy Efficient Technology

Combined Heat and Power

Combined heat and power (CHP), or cogeneration, is a clean, efficient, and sustainable approach to generating power from a single fuel source. Wastewater treatment plants with anaerobic digesters installed produce methane gas as a by-product of digestion. Traditionally, these facilities convert the methane to carbon dioxide and release it into the atmosphere. However, a cleaner and more efficient way of managing methane is to actually utilize it as an energy source. CHP systems are designed to meet the specific energy needs of wastewater treatment plants, and can significantly enhance operational efficiency while decreasing energy costs. In addition, CHP systems are beneficial to the environment in that they reduce greenhouse gas emissions, which contribute to climate change, which contributes to water scarcity and degradation — a damaging cycle.

In Conclusion

Energy efficiency in wastewater treatment operations is certainly the wave of the future. Because of increased loads and decreased budgets, municipal wastewater treatment plants are finding it necessary to implement cost-effective solutions in order to operate sustainably. Implementing an energy audit and incorporating energy efficient strategies into day-to-day operations at wastewater treatment facilities will provide significant economic and environmental benefits, and provide a safe, clean future for generations to come.