Providing a Roadmap to Successful, Affordable Infrastructure Improvement

It seems that every day there is an exciting new product on the market to make every task that much easier and faster. A new tip on how one can achieve maximum productivity in their career, workouts, cooking, and how to achieve maximum energy saving capabilities in your homes — you name it, if there’s a will to optimize productivity, there’s a way for efficiency.

The same goes for your local water, wastewater and stormwater system.

The Tata & Howard Capital Efficiency Plan (CEP) helps you do just that. Our CEP method is an accelerated and progressive approach to asset management. Our program allows municipalities, with the assistance and guidance of expert field staff and project managers, to do the following: (1) identify areas of their water, stormwater, and wastewater systems that are in need of repair, replacement, and/or rehabilitation; and (2) create a prioritized plan of action that is easily justified. In addition, the entire plan is conducted and completed in a way that makes the most bang out of municipalities’ limited infrastructure bucks.

The Tata & Howard Capital Efficiency Plan (CEP) helps you do just that. Our CEP method is an accelerated and progressive approach to asset management. Our program allows municipalities, with the assistance and guidance of expert field staff and project managers, to do the following: (1) identify areas of their water, stormwater, and wastewater systems that are in need of repair, replacement, and/or rehabilitation; and (2) create a prioritized plan of action that is easily justified. In addition, the entire plan is conducted and completed in a way that makes the most bang out of municipalities’ limited infrastructure bucks.

What’s the Plan?

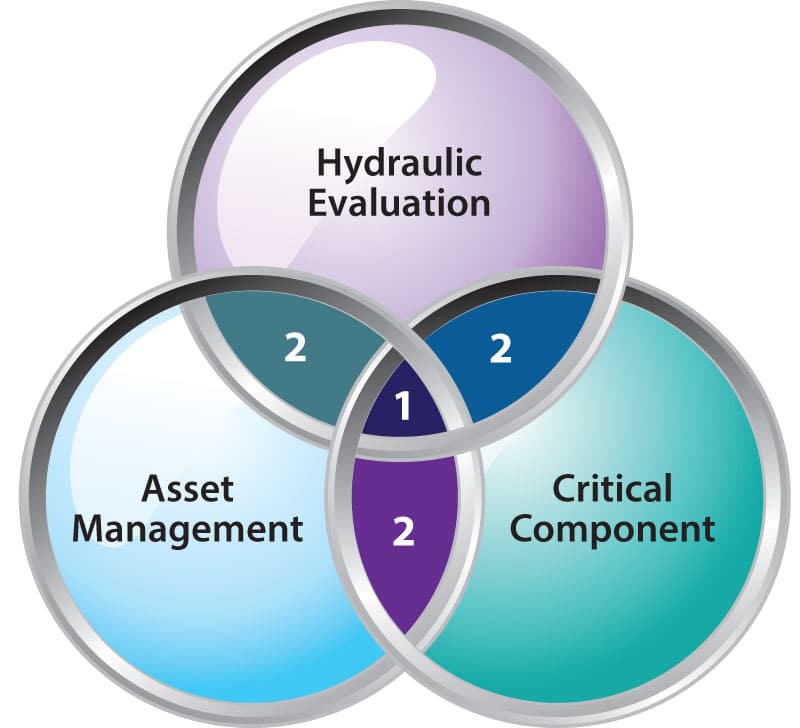

Our CEP uses a three-circle, Venn diagram method. The three circles each represent a set of evaluation criteria for each water main segment: hydraulic modeling, asset management, and critical components. Each set comes with its own set of weaknesses. As with a typical Venn diagram, there is some overlap between the three circles, and the overlaps highlight the problem areas in the system. If a weakness appears to fall into more than one criteria set, they are given a higher priority than the others. By using this visual approach, our CEP easily and concisely identifies areas of criticality that allows systems to then create an action plan.

Once the plan is completed, systems receive their CEP report, complete with Geographic Information System (GIS) representation for each pipe segment within their individual underground piping system, along with a database. Each report will detail what issues are critical and should be prioritized, and includes estimated costs for the repairs, replacements, or rehabilitations that need to be made, so critical and less-critical projects alike can be part of the conversation when preparing annual budgets.

Once the plan is completed, systems receive their CEP report, complete with Geographic Information System (GIS) representation for each pipe segment within their individual underground piping system, along with a database. Each report will detail what issues are critical and should be prioritized, and includes estimated costs for the repairs, replacements, or rehabilitations that need to be made, so critical and less-critical projects alike can be part of the conversation when preparing annual budgets.

Road Blocks

In their 2021 Report Card, the American Society of Civil Engineers (ASCE) gave wastewater an embarrassing “D+” grade due to the existing infrastructure being in desperate need of repair and replacement and drinking water a “C-“. Stormwater came in with the lowest grade of “D”.

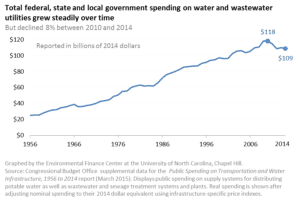

It has been no secret that federal and state funding has been on a steady decline for several decades now, starting in the mid-1970s. With already limited funding, state and local governments are unable to meet full capital expenditures and to prioritize projects, and are frankly falling behind, leaving their residents to bear the burden of crumbling infrastructure.

It has been no secret that federal and state funding has been on a steady decline for several decades now, starting in the mid-1970s. With already limited funding, state and local governments are unable to meet full capital expenditures and to prioritize projects, and are frankly falling behind, leaving their residents to bear the burden of crumbling infrastructure.

Our plan allows systems to implement clear, concise, and systematic plans of action, have more detailed agendas for each project, and to better allocate their already limited funding while providing critical repair, replacement, and/or rehabilitation of their water, wastewater, or stormwater system. CEP’s also provide a roadmap for a better plan for future work, resulting in tackling more capital improvement projects, all while using fewer funds. It is a win across the board, as evidenced by the following systems:

Asset management planning is absolutely critical to the current and future health and maintenance of our water supplies. This highly structured, three-circle approach to capital planning is one of the most effective ways for systems to conclusively prioritize those that are in most need of repair, replacement, or rehabilitation. Each CEP approach is specifically tailored to each project, as each system and project have varying needs.

Asset management planning is absolutely critical to the current and future health and maintenance of our water supplies. This highly structured, three-circle approach to capital planning is one of the most effective ways for systems to conclusively prioritize those that are in most need of repair, replacement, or rehabilitation. Each CEP approach is specifically tailored to each project, as each system and project have varying needs.

By participating in our Capital Efficiency Plan and actively working towards better capital planning, systems can achieve better capital efficiency. Our plan will give its participants the security knowing that their annual budgets are better allocated to the most critical projects, and provide a sigh of relief knowing that their repair-to-do lists are getting shorter. And, most importantly, systems can rest assured knowing that their residents have access to safe, clean drinking water via updated water distribution systems.

It truly is a win-win for all.

In recent years, water systems have been faced with challenges that are unique to modern times. Our nation’s buried infrastructure is reaching a critical juncture in that it is nearing or has reached the end of its useful life, or is in dire need of replacement due to the presence of lead. At the same time, climate change is affecting supplies, while a burgeoning population is creating a larger demand. And as we increase our knowledge about the dangers of additional contaminants in our drinking water, utilities are saddled with increased regulations that require strict compliance by specific deadlines. Obtaining compliance often requires extensive upgrades or completely new infrastructure, all of which come with a high price tag.

In recent years, water systems have been faced with challenges that are unique to modern times. Our nation’s buried infrastructure is reaching a critical juncture in that it is nearing or has reached the end of its useful life, or is in dire need of replacement due to the presence of lead. At the same time, climate change is affecting supplies, while a burgeoning population is creating a larger demand. And as we increase our knowledge about the dangers of additional contaminants in our drinking water, utilities are saddled with increased regulations that require strict compliance by specific deadlines. Obtaining compliance often requires extensive upgrades or completely new infrastructure, all of which come with a high price tag. The proposed 2018 budget also budget cuts the Environmental Protection Agency (EPA) by 31%, or $5.7 billion. The EPA provides funding to water systems through its Drinking Water State Revolving Fund (DWSRF) and Clean Water State Revolving Fund (CWSRF) programs, both of which “provide communities a permanent, independent source of low-cost financing for a wide range of water quality infrastructure projects.”2 Considering that almost all spending on critical infrastructure such as drinking water, wastewater, and transportation is provided by the public sector, these cuts are expected to make a huge impact on available funding for critical water infrastructure projects.

The proposed 2018 budget also budget cuts the Environmental Protection Agency (EPA) by 31%, or $5.7 billion. The EPA provides funding to water systems through its Drinking Water State Revolving Fund (DWSRF) and Clean Water State Revolving Fund (CWSRF) programs, both of which “provide communities a permanent, independent source of low-cost financing for a wide range of water quality infrastructure projects.”2 Considering that almost all spending on critical infrastructure such as drinking water, wastewater, and transportation is provided by the public sector, these cuts are expected to make a huge impact on available funding for critical water infrastructure projects.

Wastewater. It’s something that will always exist, and will always require collection and treatment. Just like improved water, improved sanitation is one of the key contributing factors to a developed nation, significantly improving public health, educational opportunity, and workforce viability. And while the United States boasts nearly 100% improved water and sanitation, there is still cause for concern.

Wastewater. It’s something that will always exist, and will always require collection and treatment. Just like improved water, improved sanitation is one of the key contributing factors to a developed nation, significantly improving public health, educational opportunity, and workforce viability. And while the United States boasts nearly 100% improved water and sanitation, there is still cause for concern. In March of 2015, the Congressional Budget Office (CBO) published a report on annual government expenditures on infrastructure, titled

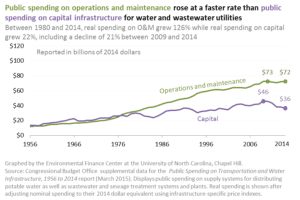

In March of 2015, the Congressional Budget Office (CBO) published a report on annual government expenditures on infrastructure, titled  To further complicate matters, capital expenditure has decreased at a faster rate than O&M expenditure. From 1956 to 1980, public spending was basically split between capital expenditures — to build or replace water and wastewater systems — and O&M of the systems. However, since 1980, O&M spending continued to grow at an annual rate of 4%-6% to the 1990s, and then at an annual rate of 1%-3% through 2009, since when it has remained flat. In contrast, capital spending grew at an annual rate of only about 1%-2% since 1980, and has declined at an average annual rate of 4% since 2009. Governments now spend twice as much on O&M of their existing systems than on capital expenditures to repair, rehabilitate, or replace existing assets or for the installation of new infrastructure. In addition, state and local government is now saddled with nearly the full burden of capital expenditure, as federal spending has been steadily on the decline since 1976.

To further complicate matters, capital expenditure has decreased at a faster rate than O&M expenditure. From 1956 to 1980, public spending was basically split between capital expenditures — to build or replace water and wastewater systems — and O&M of the systems. However, since 1980, O&M spending continued to grow at an annual rate of 4%-6% to the 1990s, and then at an annual rate of 1%-3% through 2009, since when it has remained flat. In contrast, capital spending grew at an annual rate of only about 1%-2% since 1980, and has declined at an average annual rate of 4% since 2009. Governments now spend twice as much on O&M of their existing systems than on capital expenditures to repair, rehabilitate, or replace existing assets or for the installation of new infrastructure. In addition, state and local government is now saddled with nearly the full burden of capital expenditure, as federal spending has been steadily on the decline since 1976.

Hydraulic modeling

Hydraulic modeling To continue as a leading industrialized nation, our wastewater utilities must not only remain safe and functional, but also progressive and up to date with current and future regulations. Because funding is declining while costs and population are increasing, it is more important than ever for wastewater utilities to methodically prioritize and plan all repairs and improvements. Only through the implementation of a well-researched and systematic course of action will utilities be prepared to provide safe and dependable wastewater services both now and in the future.

To continue as a leading industrialized nation, our wastewater utilities must not only remain safe and functional, but also progressive and up to date with current and future regulations. Because funding is declining while costs and population are increasing, it is more important than ever for wastewater utilities to methodically prioritize and plan all repairs and improvements. Only through the implementation of a well-researched and systematic course of action will utilities be prepared to provide safe and dependable wastewater services both now and in the future.