The Meatpacking Industry Changed How We Treat Drinking Water

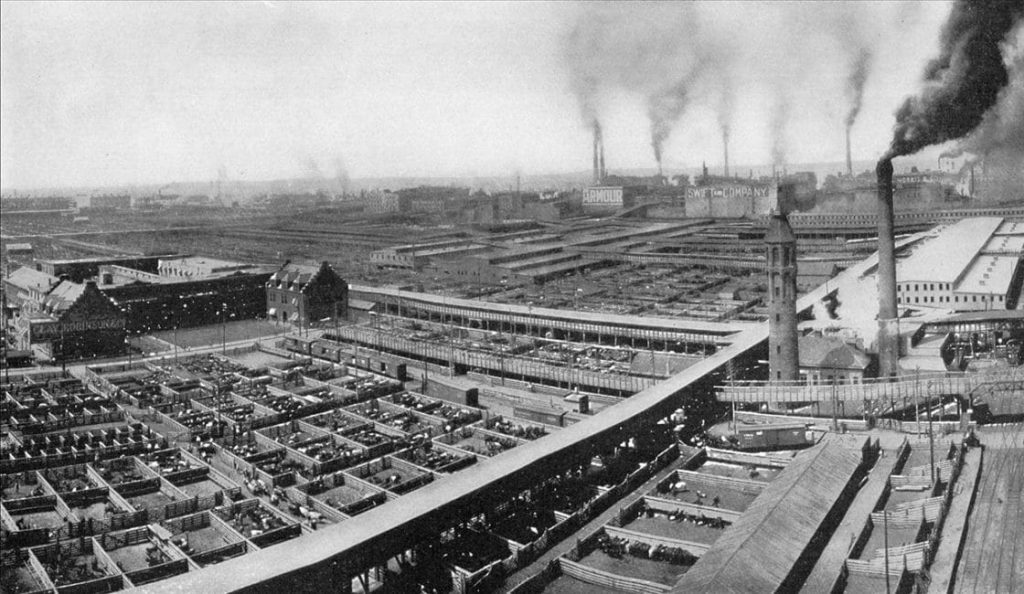

In 1906, Upton Sinclair published his book The Jungle, and shocked the nation by bringing to light the extreme health violations and unsanitary practices occurring in the country’s meatpacking industry. The public outcry eventually led to reforms including the Federal Meat Inspection Act (FMAI) of 1906.

The reforms, at the turn of the century, of the filthy stockyards and contaminated facilities had another unlikely connection to the country’s water treatment practices.

Late in the summer of 1908, the livestock at the Chicago’s Union Stockyards, had trouble gaining weight. It was suspected, the problem was the cattle’s drinking water. It seemed that the cattle only gained weight when given Chicago city water and not from the filtered drinking water supplied from a nearby creek.

The creek known as Bubbly Creek was a polluted tributary of the Chicago River, foul with decaying animal parts from the upstream meatpacking facilities and ‘bubbling’ with oozing methane and hydrogen sulfide. A nearby filtration plant cleared the water of particles and debris before it was distributed to the animal drinking troughs, but the smell of rotten eggs was overwhelming. Poaching water from City’s water supply was illegal and the Bubbly Creek was the stockyard’s only other water source.

To supply the stockyard with clean water, something had to be done.

Filtration and Disinfection

The Chicago Union Stockyards hired George A. Johnson of the New York firm of Hering & Fuller to test the quality of the Bubbly Creek’s filtered water. Although he confirmed the filtration process was satisfactory, the bacterial count was extreme due to the high content of organic matter in the water.

Johnson began testing a germicide known as “chloride of lime” or bleaching powder in the filtered water. The results were astounding. With the addition of the chlorine disinfection, filtered Bubbly Creek water became cleaner that Chicago municipal water! The Union Stockyard’s drinking water problem was solved.

Years later, Johnson would use the example of Bubbly Creek to demonstrate that filtration and disinfection, were equally important in the treatment of safe drinking water.

Chlorine Used to Treat Drinking Water

The first use of bleaching powder, or chloride of lime, as a disinfectant was temporarily introduced in 1897 to the water distribution mains in Maidstone, England to treat a typhoid epidemic. During another typhoid epidemic of 1904-05, bleaching powder was used again to disinfect the water supply in Lincoln, England. Chlorination, it was thought, could disinfect and kill certain bacteria and other waterborne diseases such as cholera, dysentery, and typhoid in water sources.

Electrolytic solutions of sea water or salt water produced the same general effect as bleaching powder and had been used for treating water, sewer and for general disinfection for the past fifteen years in England, France and China.

But the first use of bleaching powder on a large-scale use in the U.S. began in 1908 and continued into 1909 at the large Boonton Reservoir owned by the Jersey City Water Supply Company. The water was treated at a rate of 40,000,000 gallons per day, primarily as a germicide to remove bacteria and was delivered to the approximately 265,000 residents of Jersey City, several miles away.

The Jersey City Water Supply Company was the first municipality to use chlorine as a disinfectant for water in the U.S.

The Best Water in the Country

Like all cities across the country at the time, Jersey City struggled with outbreaks of typhoid fever, especially during high bacterial counts from high water and floods. Typhoid could be transmitted through unsanitary water and the death rates from the city were recorded as high as 80 per 100,000 people in the early 1900’s.

At the Boonton Reservoir, Dr. John L. Leal, an advisor to the Jersey City Water Supply Company was consulted to solve the bacteria problem in the drinking water. In the past, Leal had experimented with electrolytic solutions of salt and liquid bleach to purify water. He had discovered that only a fraction of a part per million (ppm) of chlorine would kill disease-causing bacteria and was convinced that adding a chemical disinfectant to the water supply was the best solution.

With an impending deadline of 90 days to treat the city’s drinking water, Leal needed to improvise a quick way to distribute chlorine. Unable to find suitable electrolytic equipment that would yield enough hypochlorite or liquid bleach, he partnered with George Warren Fuller, a filtration expert at Hering & Fuller. This was very same firm only a few years earlier, George Johnson used powdered ‘chloride of lime’ to disinfectant Bubble Creek in Chicago.

Fuller designed a ‘sterilization’ system that would dissolve 5 pounds of bleaching powder per 1,000,000 gallons (as a bactericide), that would cause a chemical reaction of 0.2 parts of available chlorine per 1,000,000 gallons of water. The water was treated as it left the Boonton Reservoir and flowed to the city.

Test results from the treated water from the Boonton Reservoir showed a dramatic decline of bacteria and the local typhoid fever rate—and according to a 1928 sanitary engineering report, “is not only of a high sanitary quality, but…it compares favorably with the best in the country.”1

History in the Making

Despite the low bacteria counts and decline in water-born illnesses, chlorinated water was not readily accepted by the City officials. Years of litigation followed between the City and the Jersey City Water Supply Company. The City was convinced the chemical treatment of the Boonton Reservoir had not proven satisfactory and the water supply company should install sewer works in the watershed. It was a political tug-of-war that ultimately proved very costly for the residents and tax payers.

In June of 1909, Leal, Fuller and Johnson presented to the American Water Works Association (AWWA) membership, the detailed account of the continuous chlorination treatment of drinking water at the Boonton Reservoir. Their argument for the low-cost and safe treatment of drinking water by chemical disinfection was finally widely accepted. By the 1920s, chlorination was a well-established primary means of disinfecting drinking water across the country.

Today, millions of people get their drinking water from the nation’s public-supply systems that is filtered and safely treated with chemical disinfectants. History was in the making over a 100 years ago at the Chicago Union Stockyards and with the unlikely connection of providing safe drinking water across the country.

1Report of W.C. Mallalieu, Sanitary Engineer consultant, New York City, 1928.

MA (ACEC/MA) for the Long Pond Water Filtration Facility in Falmouth, MA. The award was presented at ACEC/MA ceremony and gala held on March 14, 2018 at the Royal Sonesta in Cambridge, Massachusetts.

MA (ACEC/MA) for the Long Pond Water Filtration Facility in Falmouth, MA. The award was presented at ACEC/MA ceremony and gala held on March 14, 2018 at the Royal Sonesta in Cambridge, Massachusetts. Engineering-News Record (ENR) New England announced in December 2017, their Regional Best Projects Winners. Methuen Construction, the contractor for the construction of this facility, was awarded two Best Projects awards: Water / Environment – Best Project and Excellence in Safety – Best Project (highest honors). Projects were evaluated on the ability of the project team to overcome challenges, contribution to the industry and community, safety and construction, and design quality.

Engineering-News Record (ENR) New England announced in December 2017, their Regional Best Projects Winners. Methuen Construction, the contractor for the construction of this facility, was awarded two Best Projects awards: Water / Environment – Best Project and Excellence in Safety – Best Project (highest honors). Projects were evaluated on the ability of the project team to overcome challenges, contribution to the industry and community, safety and construction, and design quality.