In layman’s terms, unidirectional flushing is water flowing in one direction: a one way traffic lane for your local water distribution system. And the process is, for the most part, as simple as that.

To elaborate a bit more, unidirectional flushing, otherwise known as UDF, is an annual process used to aid and maintain water distribution systems like the one in your local area that provides your drinking water. We at Tata & Howard designed UDF programs specifically to remove unwanted tastes, odors, and discoloration in a water supply, to flush out bacteria and tuberculation that has built up, prolong the life of pipes and hydrants, allow for technicians to locate broken valves and hydrants, and to further pinpoint other water quality and supply issues.

Bye, Bye, Bacteria

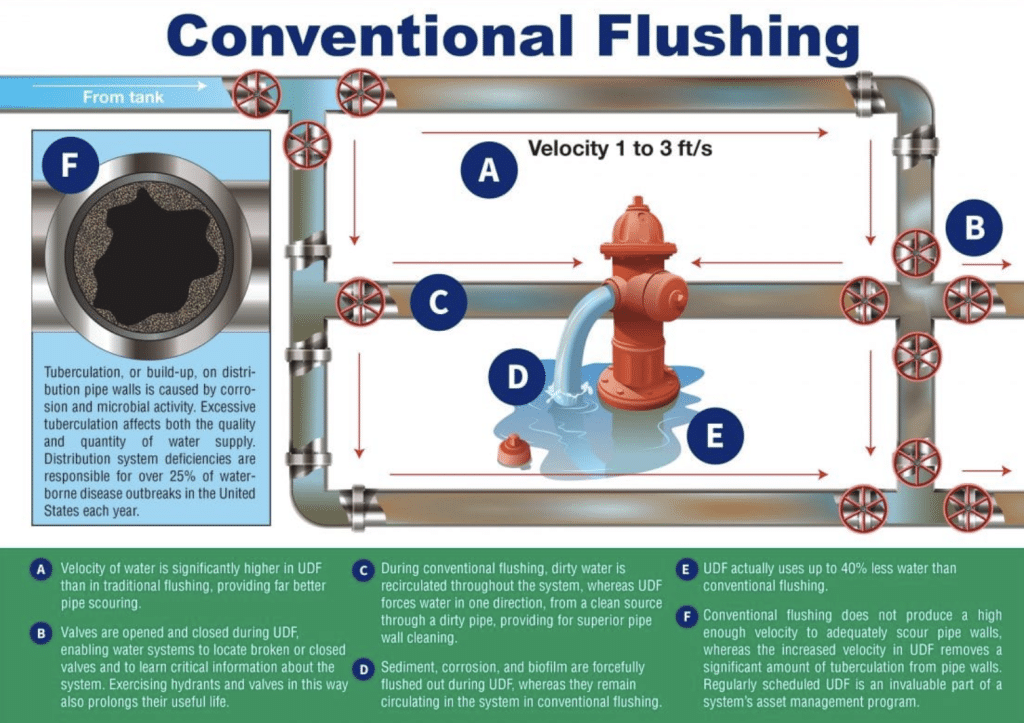

What does flushing water in one direction have anything to do with preventing water-borne disease? For starters, let’s examine the diagram below of a water distribution system that utilizes conventional flushing.

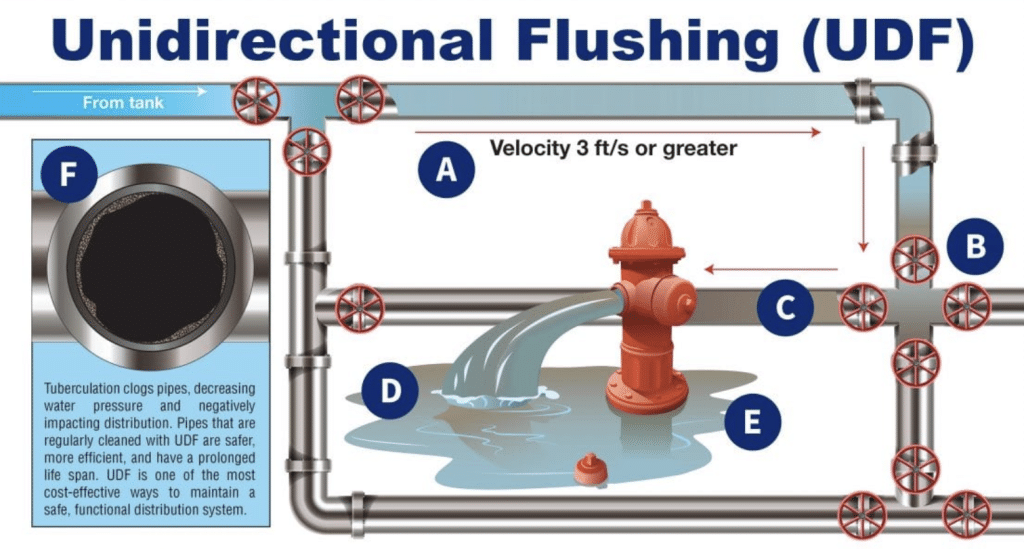

As shown in the diagram, clean water is flowing from the tank into the water distribution system but is met with the free-flowing sediment and rust-mixed water from every direction. The direction in which the water flushes is crucial because the one-way water flow keeps the tainted water separate from the clean water, unlike the conventional flushing pictured above. With this method, sediment, microbial bacteria, corrosion, etc. are not circulated in the clean water, therefore preventing it from making into your next glass of water.

Since tainted water isn’t being fully flushed out in conventional flushing, sediment, rust, and microbial bacteria are building up within some of the pipe’s walls. This build up, or tuberculation, can negatively affect how much water can be distributed.

Under Pressure (Washing)

A great component of UDF is that the water is flushed throughout the distribution system at a higher velocity. If the water rushing down these pipes is at a higher velocity, that means tuberculation that has built up in the pipe’s walls will wash away, too. Picture it like your water distribution system’s very own water pressure system, blasting away microbial and rust buildup, and tossing it out with the rest of the bath water.

In Municipal and Sewer and Water Magazine, Shrewsbury, MA water and sewer superintendent — and Tata & Howard client — Dan Rowley states that when fire hydrants are opened to increase the water velocity, it “increases to 5 to 10 feet per second, compared to 1 to 3 feet per second in conventional flushing.” With that kind of power, tuberculation doesn’t stand a chance.

Now, when some people think of ramping up the speed dial on something, they think more power equals more resources, but that’s not the case here. UDF uses upwards of 40% less water than conventional flushing. A higher population to serve brings a higher water demand, which leads to a lower supply due to demand and climate change. All of this then results in a crucial need to seek out the most cost-effective and sustainable methods in order to maintain, improve, and prolong our planet’s natural resources. And UDF does just that.

Improve System Performance

During the unidirectional flushing process, valves are opened and closed to maintain a unidirectional flow. In the process, broken and closed valves as well as nonfunctioning hydrants are identified. Not only are you cleaning the water pipes during the UDF process, you are also identifying critical system components such as valves and hydrants that need replacement or maintainance.

Regardless, any water distribution system needs flushing. So why not perform it in such a way that you can simultaneously flush our tuberculation and bacteria from your pipes’ walls, prolong the quality of your valves, hydrants and pipes, use less water, and also improve overall water quality and quantity issues? This is one of those win-win situations!

At Tata & Howard, our UDF programs are implemented all over Massachusetts, ranging from Shrewsbury to Wayland, and Melrose to Haverhill, and down to parts of Connecticut. By adopting one of our UDF programs, a water distribution system can maintain efficiency and cleanliness longer between flushes, save money, and ultimately use less of our earth’s natural resources.

Tata & Howard, Inc. has announced the retirement of Tata & Howard Co-Founder and Senior Vice President Paul Howard as of December 31, 2022. While he is stepping down from day-to-day operations, Mr. Howard will remain on the Board of Directors and serve as a technical advisor to the current leadership team led by Karen Gracey, P.E. and Jenna Rzasa, P.E., who were named Co-Presidents in 2017.

Tata & Howard, Inc. has announced the retirement of Tata & Howard Co-Founder and Senior Vice President Paul Howard as of December 31, 2022. While he is stepping down from day-to-day operations, Mr. Howard will remain on the Board of Directors and serve as a technical advisor to the current leadership team led by Karen Gracey, P.E. and Jenna Rzasa, P.E., who were named Co-Presidents in 2017.