From large power plants to water distribution networks, utility assets form the backbone of our modern-day society. They provide us with the essential services we rely on daily, from electricity to clean water and beyond. However, the sheer scale and complexity of these assets demand a systematic and strategic approach to maximize their optimal performance, safety, and longevity.

This is where asset management comes into play. Utility asset management is not only about providing smooth operations and reliable service delivery, but it also plays a pivotal role in building sustainable, future-ready systems that can withstand the challenges of a dynamic world.

So, let’s get into it!

The Basics: What is Asset Management?

Utility asset management is a systematic process in which utility companies can manage and maintain their physical assets, such as water, gas, electricity, and their corresponding infrastructures. These infrastructures can range from pipelines and power lines to meters and transformers, even staff, encompassing any essential utility delivery service and technology.

Utility asset management takes into account the entire lifecycle of an asset, from acquisition or construction to decommissioning or replacement. This type of “lifecycle evaluation” includes decisions on when to repair, refurbish, or replace assets based on specific factors, such as technological advancements, regulatory changes, and cost-effectiveness.

These programs provide utilities the opportunity to maintain accurate and up-to-date records of all of their assets, including location, specifications, maintenance history, and current condition. All of these factors contribute to an effective plan for the safety, efficiency, durability, and reliability of these assets, while also maximizing the value of their investments over the asset’s lifespan.

Now that we’ve covered the what, let’s evaluate the why.

Why is Asset Management Necessary?

Knowledge is Power: A Predictive Maintenance Mindset

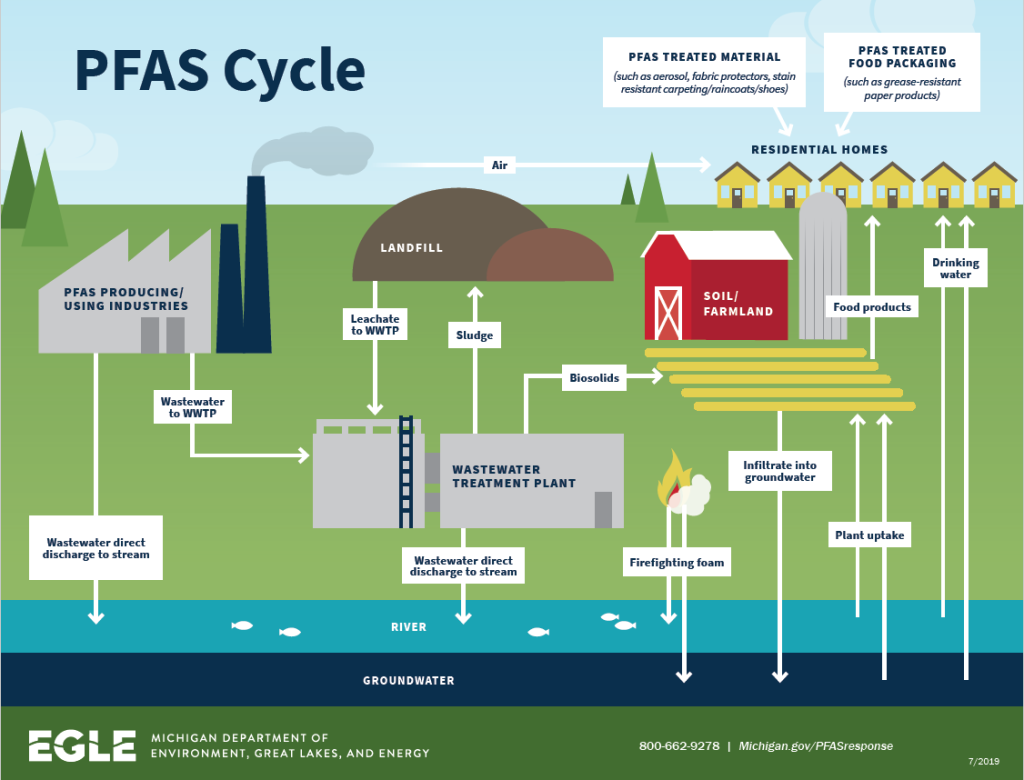

Try to think of asset management as a type of predictive maintenance: with asset management, utilities — like water works — can be proactive by utilizing available life cycle data and industry experience to anticipate just when maintenance is needed. These predictions further optimize maintenance schedules and can substantially reduce downtime and operational costs. Additionally, these programs allow for more sustainable infrastructure opportunities by offering details on potential issues, deterioration, or future risks, and provide other guidelines on how to prevent unexpected failures while simultaneously allowing for timely maintenance and/or repair.

High Scalability Meets Compliance Regulations

Asset management has a high scalability, making it a critical tool for all water, wastewater, stormwater, and public works systems, regardless of their size. Due to the adaptiveness of the program, utilities need to align their asset management efforts with relevant industry regulations and standards for optimal safety, environmental compliance, and public welfare. Like any kind of public works, utilities are subject to various environmental regulations that govern emissions, waste disposal, and resource usage.

What may be surprising to some is that utilities must also consider data security and privacy regulations. Protecting sensitive information related to assets, maintenance, and operations is essential to complying with data protection laws and other compliance regulations. (Yes, there’s loads of personally identifiable information on utility bills!)

Utility operations require permits and licenses from regulatory authorities, which are all collected during a preliminary assessment. Since asset management procedures involve tracking and renewing these permits, utilities can rest assured knowing that all necessary legal requirements are met.

By incorporating regulatory compliance into utility asset management, utilities receive continuous monitoring of regulatory changes, and often collaborate with legal and regulatory experts. Integrating compliance considerations into asset management strategies assists utility companies in maintaining operations that are lawful, safe, and environmentally responsible.

Endgame Goals

So, what is the end goal when implementing utility asset management? That’s easy: to continuously improve the reliability, safety, efficiency, and longevity of these assets while also optimizing costs and delivering high-quality services to customers.

Essentially, an effective utility asset management program results in (but is not limited to) the following:

- Reduced operational costs

- Improved service reliability

- Minimized downtime

- Enhanced customer satisfaction

- Better resource allocation

- Infrastructure stability

- Operational resiliency

- Community sustainability

How Can Tata & Howard Help?

At Tata & Howard, we start off a client’s asset management program by conducting a preliminary assessment of above and below ground infrastructures, staffing, and condition of assets. We review all existing documentation, records, drawings, and reports prior to the preliminary assessment. Once the pre-preliminary assessment has been completed, a site visit is arranged to review all of the utilities’ infrastructures and assets, and data is collected pertaining to equipment type, installation dates, capacities, manufacturers, model and serial numbers, and more; all of which is vital in providing our clients an in-depth and effective report.

So, what happens after our assessment? For starters, we provide utilities a full report on recommendations for prioritizing funds for individual asset replacement based on the criticality of the replacement, the current condition of the asset, its age, and any potential risks. Included is a Five-Year Asset Replacement Plan that includes an estimate of potential construction costs. Our findings and reports help utilities to allocate resources effectively by identifying which assets need immediate attention, which ones can be deferred, and which new investments will bring the most value in terms of performance improvement or cost savings.

In Conclusion

In summary, asset management planning is absolutely critical to the current and future health and maintenance of our utility supplies. It requires a combination of data-driven strategies, technological integration, and informed decision-making so that utility assets perform optimally throughout their lifecycle. At Tata & Howard, our team specializes in comprehensive utility asset management solutions. With years of experience, our team of experts is dedicated to delivering exceptional utility asset management services that empower water, wastewater, and stormwater utilities and companies to operate efficiently, meet regulatory requirements, and contribute to the well-being of the communities they serve.

In addition, Tata & Howard co-founder Paul Howard, P.E. was presented with an Honorary Member Award for his decades of selfless contributions to the water sector. He was presented the award alongside longtime client Phil Guerin from the City of Worcester, who was also given an Honorary Membership.

In addition, Tata & Howard co-founder Paul Howard, P.E. was presented with an Honorary Member Award for his decades of selfless contributions to the water sector. He was presented the award alongside longtime client Phil Guerin from the City of Worcester, who was also given an Honorary Membership. Finally, T&H Vice President Jon Gregory, P.E. was elected Third Trustee of MWWA, meaning he will advance to MWWA President in five years. Congratulations to all!

Finally, T&H Vice President Jon Gregory, P.E. was elected Third Trustee of MWWA, meaning he will advance to MWWA President in five years. Congratulations to all!

The first week of the month saw the start of our month-long food drive to the

The first week of the month saw the start of our month-long food drive to the  Every Tuesday this October, the T&H crew will break out into teams for the month-long Family Feud competition. We even have our very own Steve Harvey! (pictured below). Not only will the weekly competition serve as a sure-fire cure for any lingering post-Monday blues, it will also foster friendly competition, a sense of togetherness, communication, and of course, a lot of laughter and light hearted entertainment! The competition started on October 3 and the final round will be held on October 24.

Every Tuesday this October, the T&H crew will break out into teams for the month-long Family Feud competition. We even have our very own Steve Harvey! (pictured below). Not only will the weekly competition serve as a sure-fire cure for any lingering post-Monday blues, it will also foster friendly competition, a sense of togetherness, communication, and of course, a lot of laughter and light hearted entertainment! The competition started on October 3 and the final round will be held on October 24. As we cannot seem to get enough friendly competition, our team brought their A-game at October 12’s Level 99 event.

As we cannot seem to get enough friendly competition, our team brought their A-game at October 12’s Level 99 event.  On October 19, 2023, T&H turned 31 years old, so cue the “happy birthday” song! We were founded on October 19, 1992 by Donald J. Tata and Paul B. Howard. This exciting anniversary was celebrated by a company-wide catered lunch where we also discussed important company initiatives. Once the business portion of the day was completed, it was time for the party to start. The company hosted a premiere of both our new website (click around and check it out!) and new

On October 19, 2023, T&H turned 31 years old, so cue the “happy birthday” song! We were founded on October 19, 1992 by Donald J. Tata and Paul B. Howard. This exciting anniversary was celebrated by a company-wide catered lunch where we also discussed important company initiatives. Once the business portion of the day was completed, it was time for the party to start. The company hosted a premiere of both our new website (click around and check it out!) and new

AMR and AMI: What’s the Difference?

AMR and AMI: What’s the Difference?

Tata & Howard presented the Donald J. Tata Engineering Scholarship Award to two deserving high school seniors this spring: Bennett Sonneborn from Natick High School and Emma Devens from Marlborough High School. Both are pursuing engineering degrees and exhibited not only exemplary GPA and grades in their classes, but were also involved in extracurricular activites and philanthropic initiatives. We had so much fun presenting them their big checks, and we wish them all the best on their college journeys. In the fall, Bennett is attending New York University and Emma is attending the Rochester Institute of Technology.

Tata & Howard presented the Donald J. Tata Engineering Scholarship Award to two deserving high school seniors this spring: Bennett Sonneborn from Natick High School and Emma Devens from Marlborough High School. Both are pursuing engineering degrees and exhibited not only exemplary GPA and grades in their classes, but were also involved in extracurricular activites and philanthropic initiatives. We had so much fun presenting them their big checks, and we wish them all the best on their college journeys. In the fall, Bennett is attending New York University and Emma is attending the Rochester Institute of Technology.

Every year during the first week of May, the American Water Works Association (AWWA) and members of the water community celebrate Drinking Water Week, a week-long campaign dedicated to educating the public about the critical role clean water plays in our daily lives.

Every year during the first week of May, the American Water Works Association (AWWA) and members of the water community celebrate Drinking Water Week, a week-long campaign dedicated to educating the public about the critical role clean water plays in our daily lives.

The Tata & Howard Capital Efficiency Plan (CEP) helps you do just that. Our CEP method is an accelerated and progressive approach to asset management. Our program allows municipalities, with the assistance and guidance of expert field staff and project managers, to do the following: (1) identify areas of their water, stormwater, and wastewater systems that are in need of repair, replacement, and/or rehabilitation; and (2) create a prioritized plan of action that is easily justified. In addition, the entire plan is conducted and completed in a way that makes the most bang out of municipalities’ limited infrastructure bucks.

The Tata & Howard Capital Efficiency Plan (CEP) helps you do just that. Our CEP method is an accelerated and progressive approach to asset management. Our program allows municipalities, with the assistance and guidance of expert field staff and project managers, to do the following: (1) identify areas of their water, stormwater, and wastewater systems that are in need of repair, replacement, and/or rehabilitation; and (2) create a prioritized plan of action that is easily justified. In addition, the entire plan is conducted and completed in a way that makes the most bang out of municipalities’ limited infrastructure bucks. Once the plan is completed, systems receive their CEP report, complete with Geographic Information System (GIS) representation for each pipe segment within their individual underground piping system, along with a database. Each report will detail what issues are critical and should be prioritized, and includes estimated costs for the repairs, replacements, or rehabilitations that need to be made, so critical and less-critical projects alike can be part of the conversation when preparing annual budgets.

Once the plan is completed, systems receive their CEP report, complete with Geographic Information System (GIS) representation for each pipe segment within their individual underground piping system, along with a database. Each report will detail what issues are critical and should be prioritized, and includes estimated costs for the repairs, replacements, or rehabilitations that need to be made, so critical and less-critical projects alike can be part of the conversation when preparing annual budgets. It has been no secret that federal and state funding has been on a steady decline for several decades now, starting in the mid-1970s. With already limited funding, state and local governments are unable to meet full capital expenditures and to prioritize projects, and are frankly falling behind, leaving their residents to bear the burden of crumbling infrastructure.

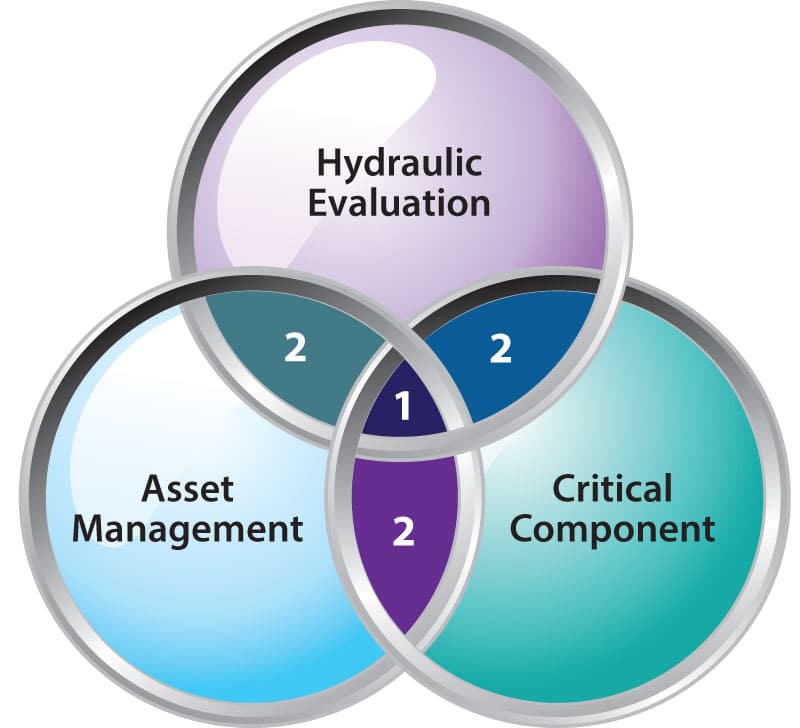

It has been no secret that federal and state funding has been on a steady decline for several decades now, starting in the mid-1970s. With already limited funding, state and local governments are unable to meet full capital expenditures and to prioritize projects, and are frankly falling behind, leaving their residents to bear the burden of crumbling infrastructure. Asset management planning is absolutely critical to the current and future health and maintenance of our water supplies. This highly structured, three-circle approach to capital planning is one of the most effective ways for systems to conclusively prioritize those that are in most need of repair, replacement, or rehabilitation. Each CEP approach is specifically tailored to each project, as each system and project have varying needs.

Asset management planning is absolutely critical to the current and future health and maintenance of our water supplies. This highly structured, three-circle approach to capital planning is one of the most effective ways for systems to conclusively prioritize those that are in most need of repair, replacement, or rehabilitation. Each CEP approach is specifically tailored to each project, as each system and project have varying needs. For example, in an effort to help remove lead pipes from Massachusetts turf, in the past we have partnered with the city of Marlborough, MA and

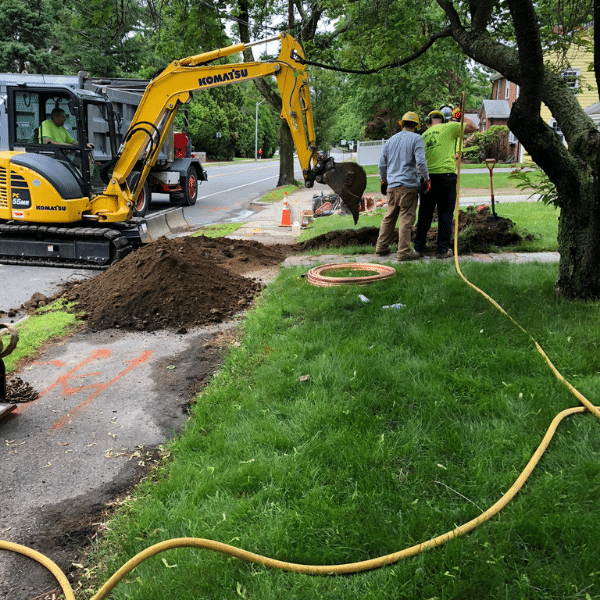

For example, in an effort to help remove lead pipes from Massachusetts turf, in the past we have partnered with the city of Marlborough, MA and For starters, let’s start with why lead is bad for us. Exposing one to lead, whether by contaminated drinking water or ingestion, can lead to severe brain and nervous system damage, kidney damage, can drastically affect children and those who are pregnant, and can cause death.

For starters, let’s start with why lead is bad for us. Exposing one to lead, whether by contaminated drinking water or ingestion, can lead to severe brain and nervous system damage, kidney damage, can drastically affect children and those who are pregnant, and can cause death.

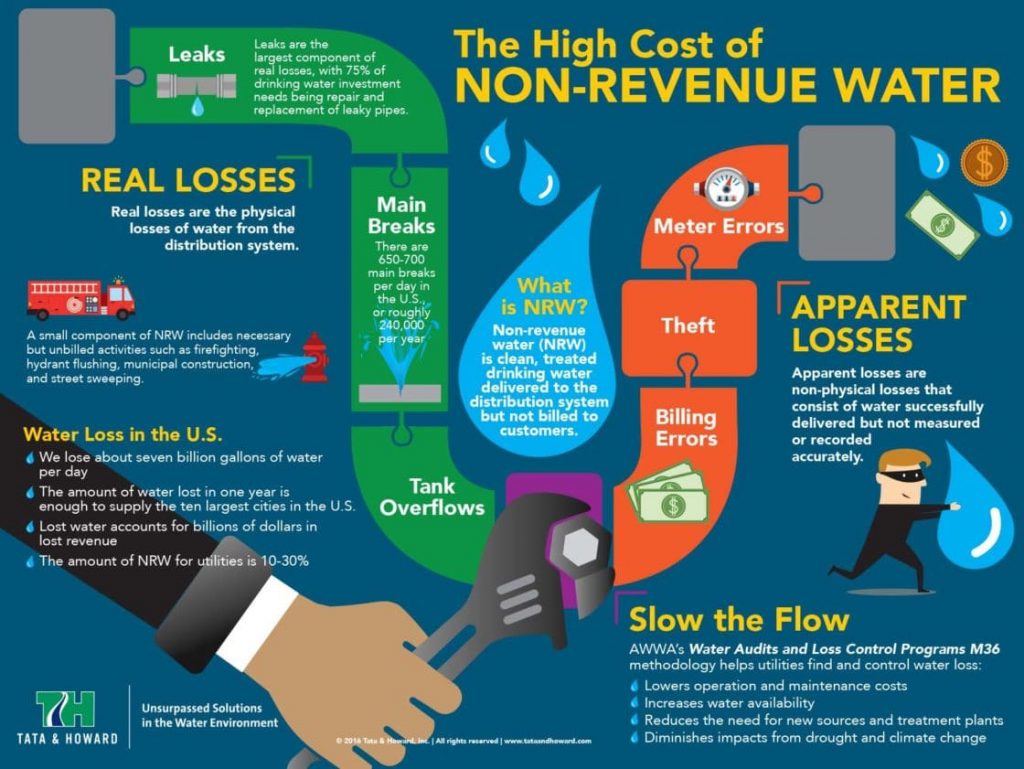

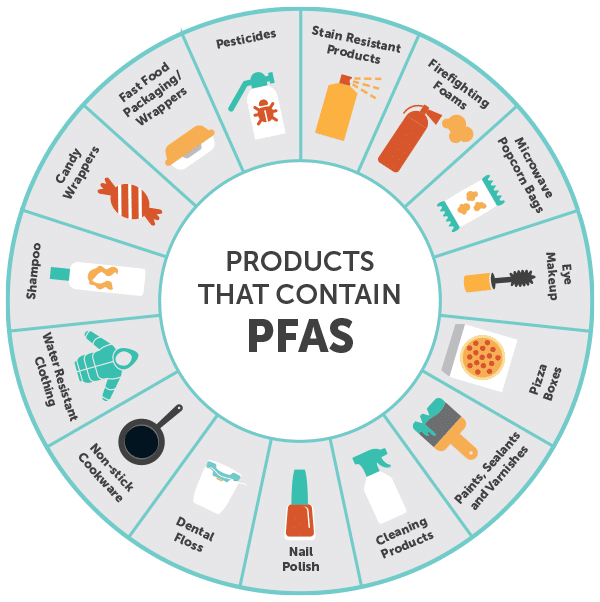

PFAS have been on the Environmental Protection Agency’s (EPA) radar for quite some time now. The question is, why is the EPA so focused on these compounds? Well, for starters, they are human-made, widely used, and nearly impossible to dissolve and break down, which means that over time they start to spread and grow, more and more, both within the human body and in our environment. These compounds are also resistant to heat, oil, grease, and water, and —what’s worse — is that the EPA has found traces of all the Unregulated Contaminant Monitoring Rule 3 (UCMR 3) (i.e., the long p-words mentioned earlier) in our country’s water supply in recent years.

PFAS have been on the Environmental Protection Agency’s (EPA) radar for quite some time now. The question is, why is the EPA so focused on these compounds? Well, for starters, they are human-made, widely used, and nearly impossible to dissolve and break down, which means that over time they start to spread and grow, more and more, both within the human body and in our environment. These compounds are also resistant to heat, oil, grease, and water, and —what’s worse — is that the EPA has found traces of all the Unregulated Contaminant Monitoring Rule 3 (UCMR 3) (i.e., the long p-words mentioned earlier) in our country’s water supply in recent years. Today,

Today,  At the end of the day, our planet’s drinking water has been affected on a national and global level thanks to the work of PFAS manufacturers. People, animals, and our entire ecosystem have been tainted. Now, water utilities are tasked with cleaning up the mess (literally). Grants are helpful but they’re not guaranteed and, frankly, $1-5 billion isn’t nearly enough for testing on a national scale, which is necessary due to the almost 100 years of damage PFAS have caused.

At the end of the day, our planet’s drinking water has been affected on a national and global level thanks to the work of PFAS manufacturers. People, animals, and our entire ecosystem have been tainted. Now, water utilities are tasked with cleaning up the mess (literally). Grants are helpful but they’re not guaranteed and, frankly, $1-5 billion isn’t nearly enough for testing on a national scale, which is necessary due to the almost 100 years of damage PFAS have caused.