The term “Lean” has become widely used in the manufacturing sector since the late 1980s when it was first used by James P. Womack, Ph.D. of MIT’s International Motor Vehicle Program to describe Toyota’s highly successful manufacturing process and business model. While its core premise of eliminating waste is quite simple, identification of waste and implementation of best practices takes effort. Waste can be defined as any process or activity without value — such as overproduction, defects, and waiting — and accounts for up to 60% of a typical manufacturing company’s production activities.

The term “Lean” has become widely used in the manufacturing sector since the late 1980s when it was first used by James P. Womack, Ph.D. of MIT’s International Motor Vehicle Program to describe Toyota’s highly successful manufacturing process and business model. While its core premise of eliminating waste is quite simple, identification of waste and implementation of best practices takes effort. Waste can be defined as any process or activity without value — such as overproduction, defects, and waiting — and accounts for up to 60% of a typical manufacturing company’s production activities.

But Lean isn’t just for manufacturing companies. In fact, most companies can benefit greatly from incorporating Lean techniques into their standard operating procedures. At its core, Lean enables a business to run more efficiently by improving quality and reducing costs, whether that company is a car manufacturer, a hospital, a retail operation — or even a water or wastewater utility.

Key Principles

The Lean Enterprise Institute (LEI), long considered the premier resource for lean theory and training, identifies the five key Lean principles as value, value stream, flow, pull, and perfection. Value is always defined through the customer, and addresses such issues as price point, delivery timelines, requirements, and expectations. Value to a water or wastewater utility may include price, quality of water or effluent, reliability of service, and meeting regulatory requirements.

The Lean Enterprise Institute (LEI), long considered the premier resource for lean theory and training, identifies the five key Lean principles as value, value stream, flow, pull, and perfection. Value is always defined through the customer, and addresses such issues as price point, delivery timelines, requirements, and expectations. Value to a water or wastewater utility may include price, quality of water or effluent, reliability of service, and meeting regulatory requirements.

Once value has been established, each and every step and process taken to meet that value is mapped as the value stream. These steps include not only manufacturing processes, but also contributing areas and departments including administrative, human resources, and customer service. By mapping every step in the process, identification of areas lacking value can be identified and addressed. Value streaming results in not only less waste, but also improved operational understanding.

Flow refers to process efficiency and is the next step after waste was been eliminated from the value stream. Often, creating true flow requires cross-functionality across departments, something that can be a challenge for companies to implement. However, this step also boasts some of the highest efficiency gains. For water and wastewater utilities, increasing flow may include moving towards transparent communication between operators and management and standardization and documentation of processes and effective practice guidelines. Ensuring that the remaining steps in the process occur smoothly and without interruption is key to the lean process.

Reducing waste in the value stream and improving flow enables a manufacturing company to shorten the manufacturing process and implement “just in time” delivery, or pull. In service operations such as water and wastewater systems, pull focuses on the people and refers to the way in which work is distributed and managed. In a traditional push system, all projects and tasks are distributed as a giant to-do list, which can lead to disorganization, diluted priorities, and employees feeling overwhelmed. In a pull system, workers are allowed to pull in tasks as they are ready, leading to a more focused approach to projects, better prioritization of key initiatives, and increased communication between workers at all levels. Organizations that utilize a pull system for work realize a significant reduction in wasted time resulting in far more efficient time utilization.

The final step may actually be the most important: perfection. Perfection refers to continuous improvement by incorporating Lean thinking into the very fabric of the corporate culture. Perfection acknowledges that true Lean requires constant effort and is never static.

Lean Implementation

Because the main goal of Lean is to create more value with fewer resources, a Lean company strives to create an organization that provides perfect value with zero waste. In addition to changing from silo to matrix management, implementing Lean follows four basic tenets, known as the four Ps of Lean thinking: purpose, process, people, and performance.

Purpose

Purpose

Companies must first determine their essential purpose. For some companies, profit may be the driving motivation, while others may exist for philanthropic purposes. Water and wastewater utilities provide an essential service to customers. Besides the general purpose of the organization, a company must also determine its philosophical drivers. These can include core values, mission, and vision.

Process

Once purpose has been determined, a company must determine the process by which it reaches its customer and produces the product, whatever that product may be. Simply put, process refers to the way in which a business operates in relation to its customer and its internal operations. Most of the key principles of Lean thinking can be applied during the process step. Unfortunately, it is also the step at which many businesses become stuck if they lose focus or lack cooperation from employees or management.

People

People refers not only to those for whom the product or service is created, but also the people within the organization who create the product or service. In other words, people are customers and employees, as well as some consultants and suppliers. Developing employees, growing leaders, improving management, and showing respect at all levels are important facets of this critical step.

Performance

Performance is the final step of the Lean approach and is in line with the perfection principle. A company must assess any improvement in its ability to deliver its product or service, and identify any additional gaps. Lean implementation typically goes through many trials and iterations before truly successful performance is achieved. Again, it is critical to remember that Lean is a continuous process that requires vigilance and ongoing effort from an organization.

Lean Thinking in Water and Wastewater Operations

Because it is often referred to as lean manufacturing, there is a misconception that Lean is strictly for manufacturing organizations. In fact, Lean is not a set of tactics or a simple method of cost reduction; rather, Lean is a completely different way of thinking and operating on an organization-wide basis.

Because it is often referred to as lean manufacturing, there is a misconception that Lean is strictly for manufacturing organizations. In fact, Lean is not a set of tactics or a simple method of cost reduction; rather, Lean is a completely different way of thinking and operating on an organization-wide basis.

For water and wastewater, Tata & Howard’s proprietary Business Practice Evaluation (BPE) is a highly effective methodology that can assist utilities in becoming lean organizations. By definition, a BPE is a “process that assesses the health of a utility’s business practices with the goal of minimizing the total cost of managing, operating, and maintaining utility assets while delivering exceptional service to customers” — the core definition of lean thinking. A BPE accomplishes this by assessing all business practices, identifying opportunities for improvement, and implementing a framework for a structured approach to managing, operating, and maintaining a utility in the same manner as a profitable business, where focus is placed on management of resources, employee engagement, operational efficiency, and customer service. The finished product provides a utility with a clear understanding of baseline history and areas of opportunity for improvement. In addition, the utility receives a matrix of recommendations for each business practice they want to improve, along with the risk and consequence of inaction. Organizations that have conducted a BPE significantly improve the operational efficiency of their utility. A BPE is arguably one of the most important steps in a water or wastewater utility’s journey toward becoming a truly Lean organization.

In Conclusion

All types of businesses across all industries and service offerings are turning toward Lean thinking to remain competitive and profitable in today’s consistently changing corporate climate. Successful Lean organizations recognize that lean is not a one-time cost reduction program or a quick fix, but rather a completely different way of thinking and operating that constantly evolves. While true Lean transformation takes long-term vigilance and attention, the benefits of increased operational efficiency, exceptional customer satisfaction, and better profitability are well worth the effort.

SaveSave

SaveSave

Municipal water treatment and distribution requires an exorbitant amount of resources, wreaking havoc on the environment and on budgets. And it’s getting worse. Over the past several years, operating costs have consistently been on the rise, while municipal budgets continue to shrink. In addition, regulatory requirements are increasing, forcing municipalities to upgrade treatment processes ahead of schedule. These changes result in limited unsustainable systems and utilities scrambling to find ways to manage their insufficient operational budgets while maintaining levels of service. The good news is that low-cost initiatives exist that can provide quick and significant cost and environmental savings and increase system sustainability.

Municipal water treatment and distribution requires an exorbitant amount of resources, wreaking havoc on the environment and on budgets. And it’s getting worse. Over the past several years, operating costs have consistently been on the rise, while municipal budgets continue to shrink. In addition, regulatory requirements are increasing, forcing municipalities to upgrade treatment processes ahead of schedule. These changes result in limited unsustainable systems and utilities scrambling to find ways to manage their insufficient operational budgets while maintaining levels of service. The good news is that low-cost initiatives exist that can provide quick and significant cost and environmental savings and increase system sustainability.

Efficiency and sustainability are no longer considered luxuries for water systems. Rather, incorporating green initiatives into infrastructure design and operational standards has become crucial to the future sustainability of water systems. And while utilities today value cost-effectiveness over environmentalism due to the criticality of their budgets, there will likely be a shift in thinking as these systems ease the burden of their unsustainable operational costs through effective practices such as efficiency and water loss reduction.

Efficiency and sustainability are no longer considered luxuries for water systems. Rather, incorporating green initiatives into infrastructure design and operational standards has become crucial to the future sustainability of water systems. And while utilities today value cost-effectiveness over environmentalism due to the criticality of their budgets, there will likely be a shift in thinking as these systems ease the burden of their unsustainable operational costs through effective practices such as efficiency and water loss reduction. Pollution Prevention Week takes place each year during the third week in September. This special week celebrates the passing of the Pollution Prevention Act in 1990, and serves as an opportunity for businesses, individuals, governments, organizations, and groups to focus on pollution prevention (P2) by celebrating their sustainability achievements, expanding current practices, and implementing new initiatives. In addition, P2 Week serves to remind individuals and organizations of the myriad ways that pollution can be prevented.

Pollution Prevention Week takes place each year during the third week in September. This special week celebrates the passing of the Pollution Prevention Act in 1990, and serves as an opportunity for businesses, individuals, governments, organizations, and groups to focus on pollution prevention (P2) by celebrating their sustainability achievements, expanding current practices, and implementing new initiatives. In addition, P2 Week serves to remind individuals and organizations of the myriad ways that pollution can be prevented.

The term “Lean” has become widely used in the manufacturing sector since the late 1980s when it was first used by James P. Womack, Ph.D. of MIT’s International Motor Vehicle Program to describe Toyota’s highly successful manufacturing process and business model. While its core premise of eliminating waste is quite simple, identification of waste and implementation of best practices takes effort. Waste can be defined as any process or activity without value — such as overproduction, defects, and waiting — and accounts for up to 60% of a typical manufacturing company’s production activities.

The term “Lean” has become widely used in the manufacturing sector since the late 1980s when it was first used by James P. Womack, Ph.D. of MIT’s International Motor Vehicle Program to describe Toyota’s highly successful manufacturing process and business model. While its core premise of eliminating waste is quite simple, identification of waste and implementation of best practices takes effort. Waste can be defined as any process or activity without value — such as overproduction, defects, and waiting — and accounts for up to 60% of a typical manufacturing company’s production activities. The Lean Enterprise Institute (LEI), long considered the premier resource for lean theory and training, identifies the five key Lean principles as value, value stream, flow, pull, and perfection. Value is always defined through the customer, and addresses such issues as price point, delivery timelines, requirements, and expectations. Value to a water or wastewater utility may include price, quality of water or effluent, reliability of service, and meeting regulatory requirements.

The Lean Enterprise Institute (LEI), long considered the premier resource for lean theory and training, identifies the five key Lean principles as value, value stream, flow, pull, and perfection. Value is always defined through the customer, and addresses such issues as price point, delivery timelines, requirements, and expectations. Value to a water or wastewater utility may include price, quality of water or effluent, reliability of service, and meeting regulatory requirements. Purpose

Purpose Because it is often referred to as lean manufacturing, there is a misconception that Lean is strictly for manufacturing organizations. In fact, Lean is not a set of tactics or a simple method of cost reduction; rather, Lean is a completely different way of thinking and operating on an organization-wide basis.

Because it is often referred to as lean manufacturing, there is a misconception that Lean is strictly for manufacturing organizations. In fact, Lean is not a set of tactics or a simple method of cost reduction; rather, Lean is a completely different way of thinking and operating on an organization-wide basis.

The truth is, there is too much at stake to keep ignoring our weakening infrastructure. If we do not do something soon, Americans may be in for some serious surprises. Imagine not being able to drink the water that comes out of our faucets or even take a shower without worrying about water borne diseases and bacteria. If we wish to seriously improve our water infrastructure, we need collaboration from all parties, both public and private. Politicians and lawmakers need to take definitive action and commit to a sustainable and reliable plan to make our water systems safe and adequate for the future. We need to make the condition of our country’s water systems a top priority.

The truth is, there is too much at stake to keep ignoring our weakening infrastructure. If we do not do something soon, Americans may be in for some serious surprises. Imagine not being able to drink the water that comes out of our faucets or even take a shower without worrying about water borne diseases and bacteria. If we wish to seriously improve our water infrastructure, we need collaboration from all parties, both public and private. Politicians and lawmakers need to take definitive action and commit to a sustainable and reliable plan to make our water systems safe and adequate for the future. We need to make the condition of our country’s water systems a top priority. Water poverty has long been considered a global crisis, with over 783 million people worldwide — that’s one in nine people — lacking access to a safe, clean water supply. Over half of the world’s hospital beds are filled with people afflicted with water-related illness, and over 80% of illnesses in sub-Saharan Africa are directly attributable to poor water and sanitation conditions. There are a plethora of charities dedicated to solving the global water crisis, including Tata & Howard’s and AWWA’s charity of choice

Water poverty has long been considered a global crisis, with over 783 million people worldwide — that’s one in nine people — lacking access to a safe, clean water supply. Over half of the world’s hospital beds are filled with people afflicted with water-related illness, and over 80% of illnesses in sub-Saharan Africa are directly attributable to poor water and sanitation conditions. There are a plethora of charities dedicated to solving the global water crisis, including Tata & Howard’s and AWWA’s charity of choice

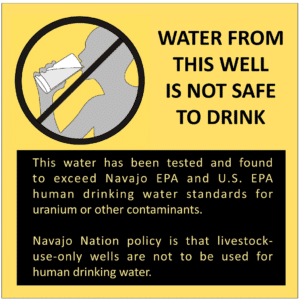

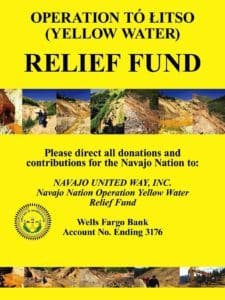

The answer to solving the water crisis of Navajo Nation is not simple. Bringing safe, clean water to the people of Navajo Nation will require both public and private investment. It will also require fair legislation that allows the Navajo to keep rights to water on their land while requiring the federal government to fund the

The answer to solving the water crisis of Navajo Nation is not simple. Bringing safe, clean water to the people of Navajo Nation will require both public and private investment. It will also require fair legislation that allows the Navajo to keep rights to water on their land while requiring the federal government to fund the  Wastewater. It’s something that will always exist, and will always require collection and treatment. Just like improved water, improved sanitation is one of the key contributing factors to a developed nation, significantly improving public health, educational opportunity, and workforce viability. And while the United States boasts nearly 100% improved water and sanitation, there is still cause for concern.

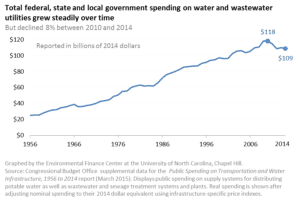

Wastewater. It’s something that will always exist, and will always require collection and treatment. Just like improved water, improved sanitation is one of the key contributing factors to a developed nation, significantly improving public health, educational opportunity, and workforce viability. And while the United States boasts nearly 100% improved water and sanitation, there is still cause for concern. In March of 2015, the Congressional Budget Office (CBO) published a report on annual government expenditures on infrastructure, titled

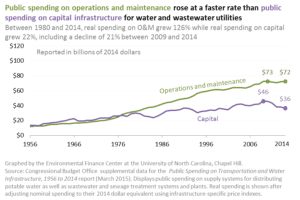

In March of 2015, the Congressional Budget Office (CBO) published a report on annual government expenditures on infrastructure, titled  To further complicate matters, capital expenditure has decreased at a faster rate than O&M expenditure. From 1956 to 1980, public spending was basically split between capital expenditures — to build or replace water and wastewater systems — and O&M of the systems. However, since 1980, O&M spending continued to grow at an annual rate of 4%-6% to the 1990s, and then at an annual rate of 1%-3% through 2009, since when it has remained flat. In contrast, capital spending grew at an annual rate of only about 1%-2% since 1980, and has declined at an average annual rate of 4% since 2009. Governments now spend twice as much on O&M of their existing systems than on capital expenditures to repair, rehabilitate, or replace existing assets or for the installation of new infrastructure. In addition, state and local government is now saddled with nearly the full burden of capital expenditure, as federal spending has been steadily on the decline since 1976.

To further complicate matters, capital expenditure has decreased at a faster rate than O&M expenditure. From 1956 to 1980, public spending was basically split between capital expenditures — to build or replace water and wastewater systems — and O&M of the systems. However, since 1980, O&M spending continued to grow at an annual rate of 4%-6% to the 1990s, and then at an annual rate of 1%-3% through 2009, since when it has remained flat. In contrast, capital spending grew at an annual rate of only about 1%-2% since 1980, and has declined at an average annual rate of 4% since 2009. Governments now spend twice as much on O&M of their existing systems than on capital expenditures to repair, rehabilitate, or replace existing assets or for the installation of new infrastructure. In addition, state and local government is now saddled with nearly the full burden of capital expenditure, as federal spending has been steadily on the decline since 1976.

Hydraulic modeling

Hydraulic modeling To continue as a leading industrialized nation, our wastewater utilities must not only remain safe and functional, but also progressive and up to date with current and future regulations. Because funding is declining while costs and population are increasing, it is more important than ever for wastewater utilities to methodically prioritize and plan all repairs and improvements. Only through the implementation of a well-researched and systematic course of action will utilities be prepared to provide safe and dependable wastewater services both now and in the future.

To continue as a leading industrialized nation, our wastewater utilities must not only remain safe and functional, but also progressive and up to date with current and future regulations. Because funding is declining while costs and population are increasing, it is more important than ever for wastewater utilities to methodically prioritize and plan all repairs and improvements. Only through the implementation of a well-researched and systematic course of action will utilities be prepared to provide safe and dependable wastewater services both now and in the future. In addition to the six Minimum Control Measures included in the original 2003 Permit, the 2016 Massachusetts MS4 General Permit also specifically includes limits to Total Maximum Daily Loads (TMDLs). TMDLs set pollution limits for affected waterways. These pollution limits represent the maximum amount of pollutant a specific body of water can handle before marine life, wildlife, and/or recreational uses become adversely affected. Because stormwater has the potential to have a significantly negative impact on waterways, TMDLs are a necessary protection measure. Unfortunately, addressing stormwater contributions to TMDLs will require that many communities make some structural and treatment modifications to their stormwater systems, and these take both time and money.

In addition to the six Minimum Control Measures included in the original 2003 Permit, the 2016 Massachusetts MS4 General Permit also specifically includes limits to Total Maximum Daily Loads (TMDLs). TMDLs set pollution limits for affected waterways. These pollution limits represent the maximum amount of pollutant a specific body of water can handle before marine life, wildlife, and/or recreational uses become adversely affected. Because stormwater has the potential to have a significantly negative impact on waterways, TMDLs are a necessary protection measure. Unfortunately, addressing stormwater contributions to TMDLs will require that many communities make some structural and treatment modifications to their stormwater systems, and these take both time and money. Fortunately, stormwater assessments that are conducted by licensed professional engineers, such as Tata & Howard’s MS4 Compliance Assessments, provide a significant return on investment. As part of the assessment, the entire system is meticulously evaluated for the most budget-conscious ways in which to fully meet compliance. Permit exclusions will also be assessed and all previous stormwater work will be documented to establish proper credit. The assessment also provides a well-planned course of action that is defendable when justifying projects and procuring funding.

Fortunately, stormwater assessments that are conducted by licensed professional engineers, such as Tata & Howard’s MS4 Compliance Assessments, provide a significant return on investment. As part of the assessment, the entire system is meticulously evaluated for the most budget-conscious ways in which to fully meet compliance. Permit exclusions will also be assessed and all previous stormwater work will be documented to establish proper credit. The assessment also provides a well-planned course of action that is defendable when justifying projects and procuring funding.