Site cleanup is well understood to be critical to the health of our planet. Since site contamination affects the quality of air, land, and water, it is clear that remediating contaminated sites is paramount to the environmental viability of the nation. However, site cleanup isn’t just about greening the nation; rather, site cleanup provides a myriad of environmental, health, and socioeconomic benefits, some of which may be surprising.

There are over 500,000 brownfields currently in the United States. A brownfield is defined as any land in the United States that is abandoned or underused because redevelopment of said site is complicated by environmental contamination. Brownfield sites are not to be confused with Superfund sites, of which there are over 1,300 in the United States. A Superfund site is a contaminated area of land that has been identified by the United States Environmental Protection Agency (EPA) as needing cleanup due to the risk it poses to environmental and/or human health. Superfund sites are placed on the National Priorities List (NPL) and are eligible for government funding through the Superfund program that was established as the Comprehensive Environmental Response, Compensation, and Liability Act of 1980 (CERCLA). Unlike Superfund sites, brownfields generally do not pose an immediate or serious risk to the environment or human health, as they typically have a lesser degree of contamination. Brownfields do, however, compromise the economic and social viability of our nation by preventing development, which causes numerous problems.

Because site cleanup can be expensive, brownfields are often left in states of ruin and decay. Brownfields disallow redevelopment, forcing communities to find new areas to develop, contributing to the degradation of inner cities and increased urban sprawl. Since we now understand that new urbanism — or the planning and development of compact cities that are walkable with accessible shopping and public spaces — promotes healthier cities and lifestyles, urban sprawl is also understood to be detrimental to the health of both cities and the environment. Cleaning up and redeveloping brownfields is one of the most effective ways to limit urban sprawl and to promote new urbanism, and fortunately, funding is available for brownfield remediation.

The EPA launched the Brownfields Program in 1995 to provide funding for brownfield remediation. The Brownfields Program includes the following grant programs:

- Brownfields Assessment Grants: funding for Brownfields inventories, planning, environmental assessments, and community outreach

- Brownfields Revolving Loan Fund Grants: funding to capitalize loans that are used to clean up brownfields

- Brownfields Cleanup Grants: funding to carry out cleanup activities at brownfield sites owned by the applicant

- Brownfields Area-Wide Planning Grants: funding to communities to research, plan, and develop implementation strategies for cleaning up and revitalizing a specific area affected by one or more brownfields sites

- Brownfields Job Training Grants: funding for environmental training for residents of Brownfields communities

In 2002, the Program was expanded when Congress passed the Small Business Liability Relief and Brownfields Revitalization Act, more commonly known as the Brownfields Law. Since the enactment of the Brownfields Law, the EPA has awarded over 1,000 grants totaling over $200 million to public and private sector organizations.

Cleaning up brownfields not only promotes new urbanism by reducing urban sprawl and inner city decay, but also increases surrounding property values, resulting in an increased tax base. These cleaned up sites allow for the utilization of existing infrastructure and transit and therefore contribute to the economic health of cities by eliminating the need for additional municipal infrastructure. Site cleanup also helps to eliminate urban arson, vandalism, and the threat of injury from dilapidated structures and areas. Since site cleanup also reduces the need to develop open land, brownfield remediation contributes to the protection of our natural resources and environment while beautifying urban landscapes. In some instances, brownfield remediation even allows for the preservation of historical landmarks and architecture that would otherwise require demolition.

And let’s not forget about health. Site cleanup eliminates the contamination that threatens our environment. Our water, air, and soil is protected from the initial contamination as well as future contamination. Even when contamination is initially minimal, deteriorating buildings and abandoned property have the potential to increase contamination as degrading building components leach into the soil and water.

One thing to keep in mind is there is some potential risk associated with brownfield remediation. If not managed or handled properly, contaminated soil could potentially result in further contamination by migrating to surrounding land through groundwater or even runoff into surface water. To significantly reduce these risks, it is recommended and often required to utilize an environmental professional when cleaning up brownfields. In Massachusetts, for example, it is required to have a Licensed Site Professional provide evaluation both before and after cleanup to ensure that all regulations, technologies, and construction best practices were strictly followed and that the contamination has been successfully remediated.

Site cleanup clearly has significant value when it comes to the health of our nation’s environment, economy, and citizens. More and more, communities are seeking to implement new urbanism and the gentrification of cities, forcing developers to seek ways to redevelop previously unusable land. With smart city planning, the availability of brownfield grants, and the utilization of environmental professionals, site cleanup will continue to provide significant value to the economic, environmental, and physical health of communities throughout the country for years to come.

Municipal water treatment and distribution requires an exorbitant amount of resources, wreaking havoc on the environment and on budgets. And it’s getting worse. Over the past several years, operating costs have consistently been on the rise, while municipal budgets continue to shrink. In addition, regulatory requirements are increasing, forcing municipalities to upgrade treatment processes ahead of schedule. These changes result in limited unsustainable systems and utilities scrambling to find ways to manage their insufficient operational budgets while maintaining levels of service. The good news is that low-cost initiatives exist that can provide quick and significant cost and environmental savings and increase system sustainability.

Municipal water treatment and distribution requires an exorbitant amount of resources, wreaking havoc on the environment and on budgets. And it’s getting worse. Over the past several years, operating costs have consistently been on the rise, while municipal budgets continue to shrink. In addition, regulatory requirements are increasing, forcing municipalities to upgrade treatment processes ahead of schedule. These changes result in limited unsustainable systems and utilities scrambling to find ways to manage their insufficient operational budgets while maintaining levels of service. The good news is that low-cost initiatives exist that can provide quick and significant cost and environmental savings and increase system sustainability.

Efficiency and sustainability are no longer considered luxuries for water systems. Rather, incorporating green initiatives into infrastructure design and operational standards has become crucial to the future sustainability of water systems. And while utilities today value cost-effectiveness over environmentalism due to the criticality of their budgets, there will likely be a shift in thinking as these systems ease the burden of their unsustainable operational costs through effective practices such as efficiency and water loss reduction.

Efficiency and sustainability are no longer considered luxuries for water systems. Rather, incorporating green initiatives into infrastructure design and operational standards has become crucial to the future sustainability of water systems. And while utilities today value cost-effectiveness over environmentalism due to the criticality of their budgets, there will likely be a shift in thinking as these systems ease the burden of their unsustainable operational costs through effective practices such as efficiency and water loss reduction. Pollution Prevention Week takes place each year during the third week in September. This special week celebrates the passing of the Pollution Prevention Act in 1990, and serves as an opportunity for businesses, individuals, governments, organizations, and groups to focus on pollution prevention (P2) by celebrating their sustainability achievements, expanding current practices, and implementing new initiatives. In addition, P2 Week serves to remind individuals and organizations of the myriad ways that pollution can be prevented.

Pollution Prevention Week takes place each year during the third week in September. This special week celebrates the passing of the Pollution Prevention Act in 1990, and serves as an opportunity for businesses, individuals, governments, organizations, and groups to focus on pollution prevention (P2) by celebrating their sustainability achievements, expanding current practices, and implementing new initiatives. In addition, P2 Week serves to remind individuals and organizations of the myriad ways that pollution can be prevented.

The term “Lean” has become widely used in the manufacturing sector since the late 1980s when it was first used by James P. Womack, Ph.D. of MIT’s International Motor Vehicle Program to describe Toyota’s highly successful manufacturing process and business model. While its core premise of eliminating waste is quite simple, identification of waste and implementation of best practices takes effort. Waste can be defined as any process or activity without value — such as overproduction, defects, and waiting — and accounts for up to 60% of a typical manufacturing company’s production activities.

The term “Lean” has become widely used in the manufacturing sector since the late 1980s when it was first used by James P. Womack, Ph.D. of MIT’s International Motor Vehicle Program to describe Toyota’s highly successful manufacturing process and business model. While its core premise of eliminating waste is quite simple, identification of waste and implementation of best practices takes effort. Waste can be defined as any process or activity without value — such as overproduction, defects, and waiting — and accounts for up to 60% of a typical manufacturing company’s production activities. The Lean Enterprise Institute (LEI), long considered the premier resource for lean theory and training, identifies the five key Lean principles as value, value stream, flow, pull, and perfection. Value is always defined through the customer, and addresses such issues as price point, delivery timelines, requirements, and expectations. Value to a water or wastewater utility may include price, quality of water or effluent, reliability of service, and meeting regulatory requirements.

The Lean Enterprise Institute (LEI), long considered the premier resource for lean theory and training, identifies the five key Lean principles as value, value stream, flow, pull, and perfection. Value is always defined through the customer, and addresses such issues as price point, delivery timelines, requirements, and expectations. Value to a water or wastewater utility may include price, quality of water or effluent, reliability of service, and meeting regulatory requirements. Purpose

Purpose Because it is often referred to as lean manufacturing, there is a misconception that Lean is strictly for manufacturing organizations. In fact, Lean is not a set of tactics or a simple method of cost reduction; rather, Lean is a completely different way of thinking and operating on an organization-wide basis.

Because it is often referred to as lean manufacturing, there is a misconception that Lean is strictly for manufacturing organizations. In fact, Lean is not a set of tactics or a simple method of cost reduction; rather, Lean is a completely different way of thinking and operating on an organization-wide basis. World Water Week is an annual event organized by the Stockholm International Water Institute (SIWI) that focuses on global water issues, and this year’s theme is “Water and Waste: Reduce and Reuse.” The main event takes place in Stockholm, Sweden where experts, innovators, stakeholders, and young professionals from various sectors around the globe will come together to share ideas, foster relationships, and develop innovative solutions to the world’s most urgent water-related problems. In 2016, over 3,300 individuals and over 330 organizations from 130 countries around the world participated in World Water Week, and the expectation is that 2017 will see at least those numbers. Through this year’s theme, World Water Week is focusing on two targets addressed by the Sustainable Development Goals (SDGs) of the UN’s 2030 Agenda for Sustainable Development including improving water quality and reducing waste by 2030 in order to help achieve sustainable development in a rapidly changing world.

World Water Week is an annual event organized by the Stockholm International Water Institute (SIWI) that focuses on global water issues, and this year’s theme is “Water and Waste: Reduce and Reuse.” The main event takes place in Stockholm, Sweden where experts, innovators, stakeholders, and young professionals from various sectors around the globe will come together to share ideas, foster relationships, and develop innovative solutions to the world’s most urgent water-related problems. In 2016, over 3,300 individuals and over 330 organizations from 130 countries around the world participated in World Water Week, and the expectation is that 2017 will see at least those numbers. Through this year’s theme, World Water Week is focusing on two targets addressed by the Sustainable Development Goals (SDGs) of the UN’s 2030 Agenda for Sustainable Development including improving water quality and reducing waste by 2030 in order to help achieve sustainable development in a rapidly changing world.

Communities lose millions of gallons of water

Communities lose millions of gallons of water

As those in the industry well know, water and wastewater treatment plants use an exorbitant amount of energy. In fact, 30-40% of total municipal energy consumption is due to water and wastewater treatment plants. In addition, energy currently accounts for 40% of drinking water systems’ operational costs and is projected to jump to 60% within the next 15 years. This excessive energy consumption places financial burden on already stressed water and wastewater utilities struggling to keep up with ever-increasing regulations and demand.

As those in the industry well know, water and wastewater treatment plants use an exorbitant amount of energy. In fact, 30-40% of total municipal energy consumption is due to water and wastewater treatment plants. In addition, energy currently accounts for 40% of drinking water systems’ operational costs and is projected to jump to 60% within the next 15 years. This excessive energy consumption places financial burden on already stressed water and wastewater utilities struggling to keep up with ever-increasing regulations and demand.

Tata & Howard provides on-call engineering services for water, wastewater, and energy related projects for the City of Flagstaff, Arizona. Several options for replacement of the blowers were evaluated and presented to the City in a report that recommended the installation of appropriately sized turbo blowers and upgrading the controls logic to automate dissolved oxygen controls.

Tata & Howard provides on-call engineering services for water, wastewater, and energy related projects for the City of Flagstaff, Arizona. Several options for replacement of the blowers were evaluated and presented to the City in a report that recommended the installation of appropriately sized turbo blowers and upgrading the controls logic to automate dissolved oxygen controls.

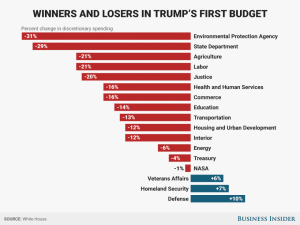

Trump’s proposed FY18 budget includes deep cuts to the nation’s major infrastructure programs. Both the DWSRF and CWSRF, funded by the EPA, are slated for drastic reduction under Trump’s budget, while the CBDG program is marked for elimination. In fact, Trump’s budget proposes to completely eliminate 66 federal programs including not only CBDG but also the United States Department of Agriculture’s Rural Water and Waste Disposal Program, and the Northern Border Regional Commission, which is a Federal-State partnership for economic and community development within the most distressed counties of Maine, New Hampshire, Vermont, and New York. Without these funding programs, some communities may not be able to implement needed system improvements.

Trump’s proposed FY18 budget includes deep cuts to the nation’s major infrastructure programs. Both the DWSRF and CWSRF, funded by the EPA, are slated for drastic reduction under Trump’s budget, while the CBDG program is marked for elimination. In fact, Trump’s budget proposes to completely eliminate 66 federal programs including not only CBDG but also the United States Department of Agriculture’s Rural Water and Waste Disposal Program, and the Northern Border Regional Commission, which is a Federal-State partnership for economic and community development within the most distressed counties of Maine, New Hampshire, Vermont, and New York. Without these funding programs, some communities may not be able to implement needed system improvements. But team building doesn’t happen by chance; rather, it requires a concentrated effort from employee-owners at all levels in order to build and maintain positive and meaningful relationships. Because of this, Tata & Howard encourages and invests in activities that bring all of us closer together. A large part of our team building comes in the form of our Employee Stock Ownership Plan (ESOP). Since 2014, 100% of the stock in Tata & Howard has been owned by the employees, and since every member of the firm is an owner, the success of the firm becomes much more personal. Just like a football team that must work together to win championships (we might be talking about the Patriots here!), we also work together to deliver the best projects to our clients, enabling us to grow the firm.

But team building doesn’t happen by chance; rather, it requires a concentrated effort from employee-owners at all levels in order to build and maintain positive and meaningful relationships. Because of this, Tata & Howard encourages and invests in activities that bring all of us closer together. A large part of our team building comes in the form of our Employee Stock Ownership Plan (ESOP). Since 2014, 100% of the stock in Tata & Howard has been owned by the employees, and since every member of the firm is an owner, the success of the firm becomes much more personal. Just like a football team that must work together to win championships (we might be talking about the Patriots here!), we also work together to deliver the best projects to our clients, enabling us to grow the firm.

We believe that our team is what sets us apart and what makes the firm special, and the firm of choice for innovative solutions in the water environment. From working together on innovative projects — like the recently completed

We believe that our team is what sets us apart and what makes the firm special, and the firm of choice for innovative solutions in the water environment. From working together on innovative projects — like the recently completed

Each municipality and utility is responsible for making sure that its assets, including water, wastewater, and/or stormwater systems, stay in good working order, regardless of the age of its components or the availability of additional funds. This requirement makes properly maintaining and monitoring assets paramount. With limited resources, an asset management plan can help municipalities and utilities maximize the value of their capital as well as their operations and maintenance dollars. Asset management is a scalable approach that can be utilized by all types of systems, of any size.

Each municipality and utility is responsible for making sure that its assets, including water, wastewater, and/or stormwater systems, stay in good working order, regardless of the age of its components or the availability of additional funds. This requirement makes properly maintaining and monitoring assets paramount. With limited resources, an asset management plan can help municipalities and utilities maximize the value of their capital as well as their operations and maintenance dollars. Asset management is a scalable approach that can be utilized by all types of systems, of any size. The

The  It is apparent that financial planning for municipalities and utilities must be based on sound asset condition projections from an engineering and operations perspective – not just financial assumptions. Customers are often adamantly against rate and tax increases; however, these sometimes-unavoidable increases are easier for customers to understand — and accept — when they are backed up with clear data showing exactly what system improvements are needed and why. There are many costs associated with municipality and utility operations and maintenance. One of these is the cost of asset ownership, a cost element not currently present in the audited financial statements of many municipalities and utilities. An asset management approach can aid municipalities and utilities in understanding the true costs associated with ownership and operation along with complying with government regulations.

It is apparent that financial planning for municipalities and utilities must be based on sound asset condition projections from an engineering and operations perspective – not just financial assumptions. Customers are often adamantly against rate and tax increases; however, these sometimes-unavoidable increases are easier for customers to understand — and accept — when they are backed up with clear data showing exactly what system improvements are needed and why. There are many costs associated with municipality and utility operations and maintenance. One of these is the cost of asset ownership, a cost element not currently present in the audited financial statements of many municipalities and utilities. An asset management approach can aid municipalities and utilities in understanding the true costs associated with ownership and operation along with complying with government regulations. Finding and detecting failures such as leaks in the system

Finding and detecting failures such as leaks in the system