Today’s volume and demand for daily water use may have changed since the town incorporated in 1881, but one goal remains constant to this day: safe water.

Team T&H continues to deliver safe, potable water through engineering excellence of precision, collaboration, feedback, and commitment between all team members, water department operators, and project managers. The Godfrey Brook WTP project scope involves construction administration and resident project representative services. Process elements of the project include biological iron and manganese pressure filters, a packed tower aerator, and chemical addition for the purpose of pH adjustment, corrosion control, and disinfection. The new WTP includes a clearwell to achieve 4-Log inactivation of viruses prior to the distribution system. The WTP also includes HVAC, plumbing, electrical, and advanced SCADA systems for monitoring and control of the new treatment plant and the wells. Site work includes new raw and finished water mains, stormwater controls in the form of a sub-grade stormwater infiltration system, and residuals storage tanks for solids handling after backwashing the biological filters, and electrical including a new electrical standby generator. The project also includes site upgrades to the wells and access road, including an RCP culvert replacement to improve drainage of Godfrey Brook (a tributary stream into the Charles River), submersible well pumps and motors for the seven wells, and a precast concrete raw water metering vault for flow control. Currently, the biological filters are in the acclimation phase, the final step prior to a performance test to confirm effectiveness of removing iron and manganese.

Located to the left of the Godfrey Brook WTP’s exterior stands a packed tower aerator (shown above). The tower aerator removes carbon dioxide to increase pH in a more cost effective manner than chemical addition, and adds dissolved oxygen before the biological manganese filters, which is critical to biological filtration.

Biological manganese filters (above) come after the packed tower aerator for efficient removal of manganese. Biological iron filter is upstream of the packed tower to optimize the performance of all downstream processes.

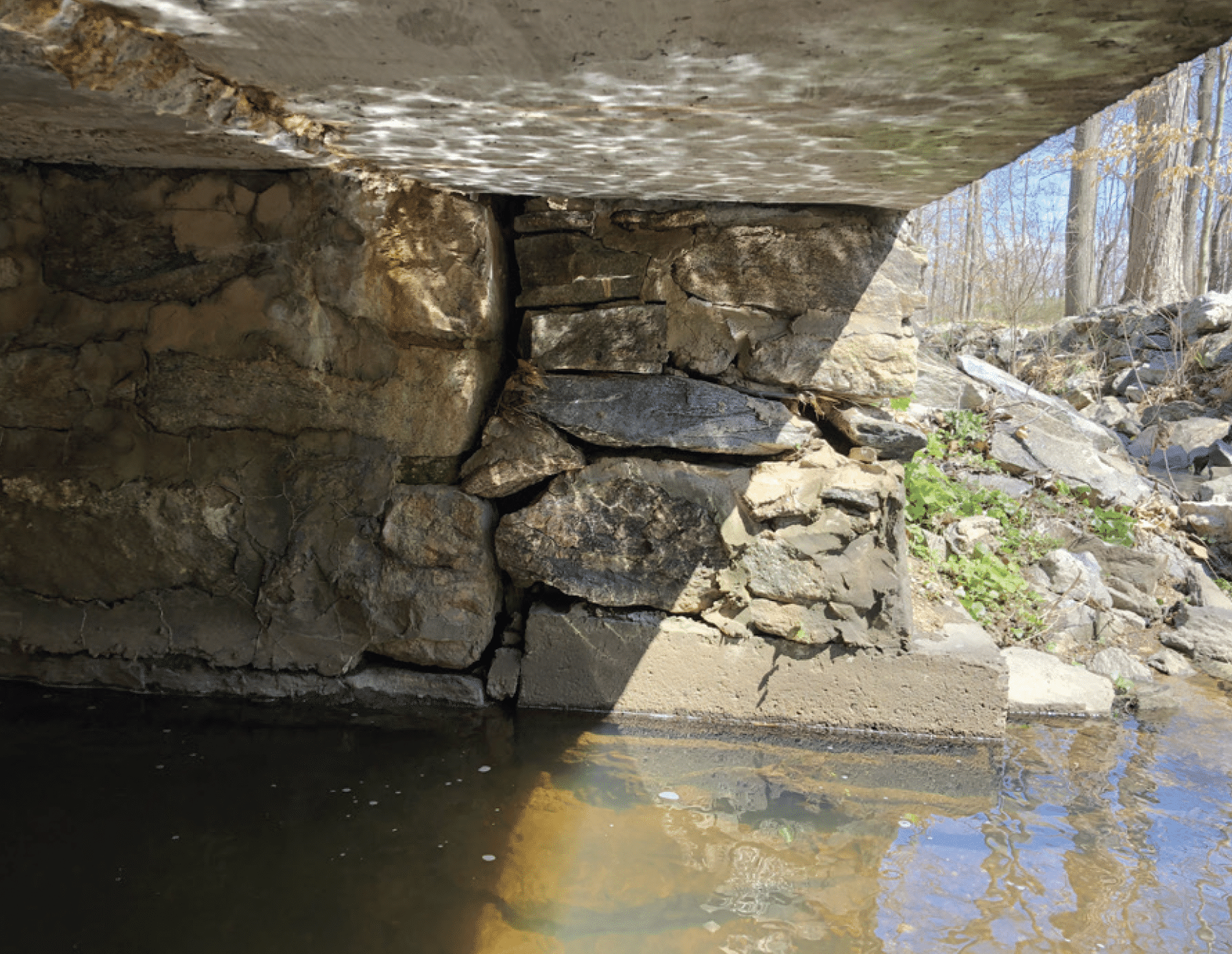

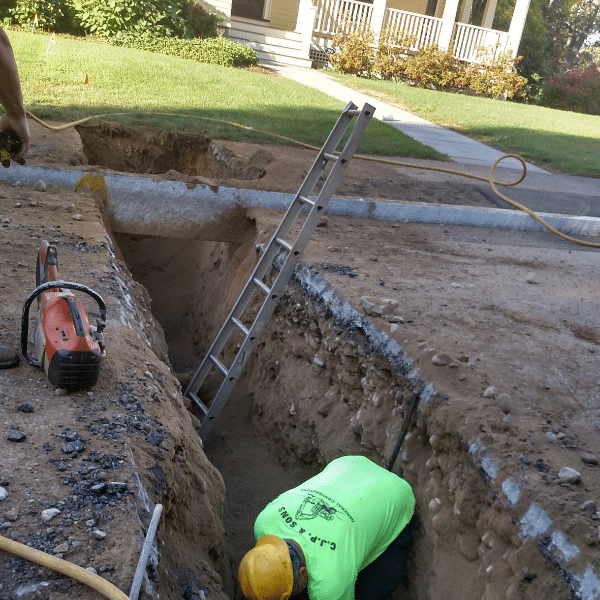

The project included a culvert reconstruction to replace a damaged pipe. Culverts are trench-like constructs designed to allow free-flowing water beneath a road or railway, whether stormwater or a stream. Pictured is the finished culvert over Godfrey Brook, a tributary to the Charles River.

T&H team members Matt O’Dowd, Juliette Burcham, Mitch Garon, and Barry Pociask review the electrical connection for the disconnect of the submersible well pump for well 1A. The Godfrey Brook Wellfield features seven total gravel packed wells: five rehabilitated and two newly installed.

The newly installed chemical feed system includes skid-mounted chemical metering pumps used for potassium hydroxide; here, chemical addition occurs for pH adjustment, along with the addition of sodium hypochlorite for disinfection and zinc orthophosphate for corrosion control prior to entering the water distribution system.