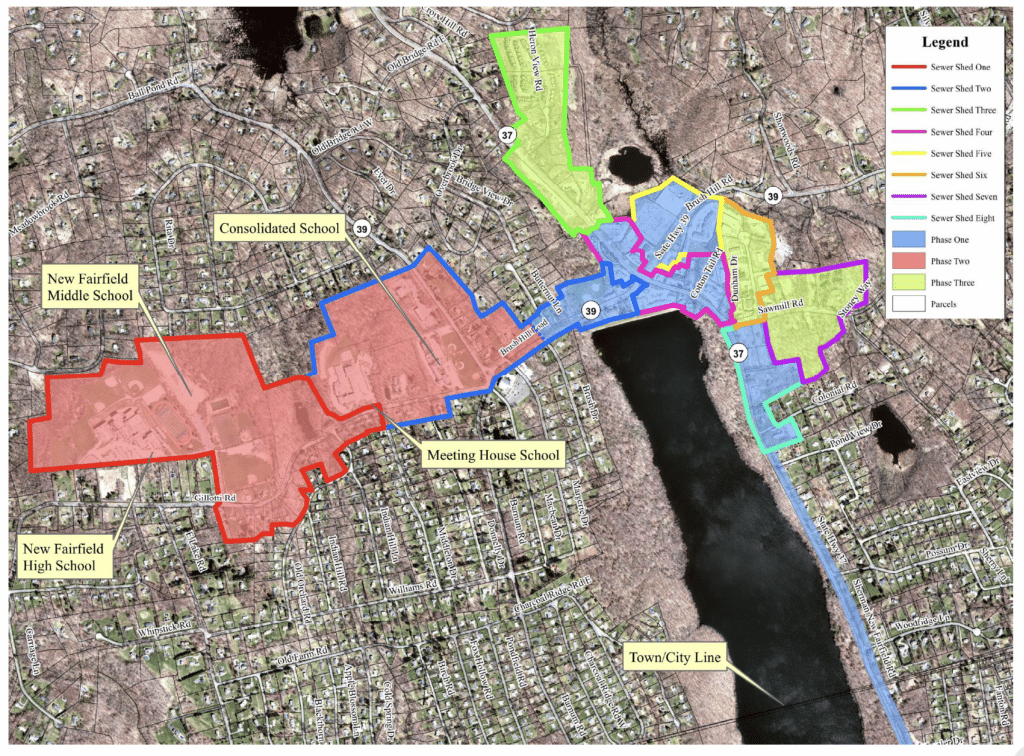

Tata & Howard completed a Sewer Feasibility Study for the Town of New Fairfield, CT to determine the feasibility of developing a sewer service area for the Town of New Fairfield town center/business district, municipal town buildings and schools, and other properties within the proposed sewer service area as well as transporting the wastewater to the City of Danbury’s Wastewater Treatment Facility. The assessment included an estimate of projected flows for all properties within the planned service area and a comparison of total estimated flows to available capacity at the Danbury Wastewater Treatment facility. Design concept plans for the planned sewer service area included determination of collection system sewers and pump station locations. Part of the study included an evaluation of potential routes for transporting flows from the Fairfield Town Center service area to the City of Danbury collection system for treatment.

Estimated project budgetary costs for the sewer service area collection system, pump stations, and transport to the City of Danbury along with a phasing and implementation plan were included in the final draft report to the Town of New Fairfield.

Estimated project budgetary costs for the sewer service area collection system, pump stations, and transport to the City of Danbury along with a phasing and implementation plan were included in the final draft report to the Town of New Fairfield.

Throughout the course of the project, a number of meetings with the Town were held to obtain Town input and comments including one meeting at the completion of the initial assessment phase, one meeting at the completion of the concept design phase, and a series of meetings and presentations at Town Selectboard meetings to obtain public input during the roll out of the final report.

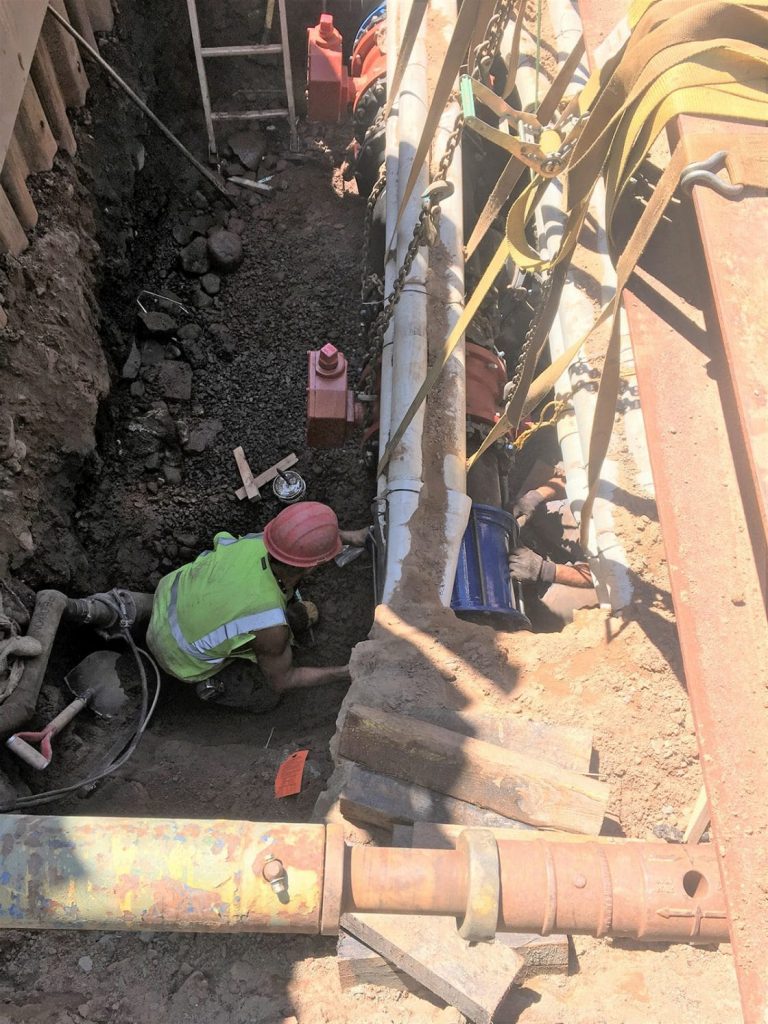

Tata & Howard provided preliminary and final design of 2.7 miles of gravity sewers, one main pump station, four remote, submersible pump stations, 2.3 miles of force mains, , and 4,000 linear feet of low pressure sewer. The project also includes identifying easements, land acquisition plans, preparation of permitting, and bidding assistance.

Tata & Howard provided preliminary and final design of 2.7 miles of gravity sewers, one main pump station, four remote, submersible pump stations, 2.3 miles of force mains, , and 4,000 linear feet of low pressure sewer. The project also includes identifying easements, land acquisition plans, preparation of permitting, and bidding assistance.

Preliminary design included survey, soil borings, preparation of base mapping, identification of utility requirements, a radio path survey and an opinion of probable cost.

Final design development includes final design of the main pump station, remote pump stations, gravity sewers, force main, and low-pressure sewers for connection to the City of Danbury collection system including site plans, profiles of force main and gravity sewers, pump station structures and chambers, electrical and controls, emergency generators, odor control, erosion and control plans, etc. Also includes design of the main pump station building designed to match the local aesthetic and mask it as a non-utility structure.

Final design development includes final design of the main pump station, remote pump stations, gravity sewers, force main, and low-pressure sewers for connection to the City of Danbury collection system including site plans, profiles of force main and gravity sewers, pump station structures and chambers, electrical and controls, emergency generators, odor control, erosion and control plans, etc. Also includes design of the main pump station building designed to match the local aesthetic and mask it as a non-utility structure.

Construction Documents will be prepared by phasing construction under four contracts:

- Year 1 – Phase 1: Main Pump Station and force main for connection to the Danbury System and Collection System for the Town Center and commercial district (Sewer Sheds 2 [commercial],

4, 5 and 8); - Year 2 – Phase 2: Collection System connecting schools, police, and fire facilities (Sewer Sheds 1 and 2 [residential]);

- Year 3 – Phase 3: Additional Collection System connecting additional commercial properties, The Birches 55+ community, The Woods at Dunham Pond 55+ community, The Good Shepherd Lutheran Church, and potential future land development along Route 37 (Sewer Sheds 3, 6, and 7).

Design services included attending the kickoff meeting with City and reviewing existing information including tie-cards, the City’s existing GIS database that includes service material, and the City’s master list of services with service material.

Design services included attending the kickoff meeting with City and reviewing existing information including tie-cards, the City’s existing GIS database that includes service material, and the City’s master list of services with service material. Construction Administration services for each phase included attendance at progress meetings and site visits, review of submittals, request for information, and purchasing change orders and payment applications. As-built record tie-cards were completed for each address and the master inventory of service material was updated as construction on each phase progressed.

Construction Administration services for each phase included attendance at progress meetings and site visits, review of submittals, request for information, and purchasing change orders and payment applications. As-built record tie-cards were completed for each address and the master inventory of service material was updated as construction on each phase progressed.  Tata & Howard provided engineering services for permitting, design, and bidding of the Trinity Avenue Pump Station at the Trinity Avenue Wellfield (new source) and provided assistance with permitting, design, and reporting to the Massachusetts Department of Environmental Protection (MassDEP) for the proposed Trinity Avenue Well site.

Tata & Howard provided engineering services for permitting, design, and bidding of the Trinity Avenue Pump Station at the Trinity Avenue Wellfield (new source) and provided assistance with permitting, design, and reporting to the Massachusetts Department of Environmental Protection (MassDEP) for the proposed Trinity Avenue Well site. The property was owned by the Massachusetts Division of Fisheries and Wildlife (DFW), and the Grafton Water District swapped land with the DFW to obtain ownership and control of the Trinity Avenue site. Test wells were installed and short-term pump tests were completed on each of the wells. Based on the results of the tests, it was recommended to install a three well configuration of 18-inch x 12-inch gravel packed wells resulting in approximately 840 gallons per minute (gpm). The work under this contract included the completion of the Request for Site Exam and Pump Test Proposal for submission to MassDEP, installation and development of three (3) 18” x 12” gravel packed wells and pitless adapters, installation and development of approximately five 2-1/2” diameter observation wells, installation of two staff gages and piezometers, performing a five-day pump test, and collection and analysis of water quality.

The property was owned by the Massachusetts Division of Fisheries and Wildlife (DFW), and the Grafton Water District swapped land with the DFW to obtain ownership and control of the Trinity Avenue site. Test wells were installed and short-term pump tests were completed on each of the wells. Based on the results of the tests, it was recommended to install a three well configuration of 18-inch x 12-inch gravel packed wells resulting in approximately 840 gallons per minute (gpm). The work under this contract included the completion of the Request for Site Exam and Pump Test Proposal for submission to MassDEP, installation and development of three (3) 18” x 12” gravel packed wells and pitless adapters, installation and development of approximately five 2-1/2” diameter observation wells, installation of two staff gages and piezometers, performing a five-day pump test, and collection and analysis of water quality. The project also included an evaluation of alternatives for the access road including installation of a bridge or an open bottomed culvert, and Tata & Howard assisted with the preparation of permanent easements for the installation of utilities and roadway to the well site. In addition, Tata & Howard prepared and submitted an NOI to the Grafon Conservation Commission.

The project also included an evaluation of alternatives for the access road including installation of a bridge or an open bottomed culvert, and Tata & Howard assisted with the preparation of permanent easements for the installation of utilities and roadway to the well site. In addition, Tata & Howard prepared and submitted an NOI to the Grafon Conservation Commission.

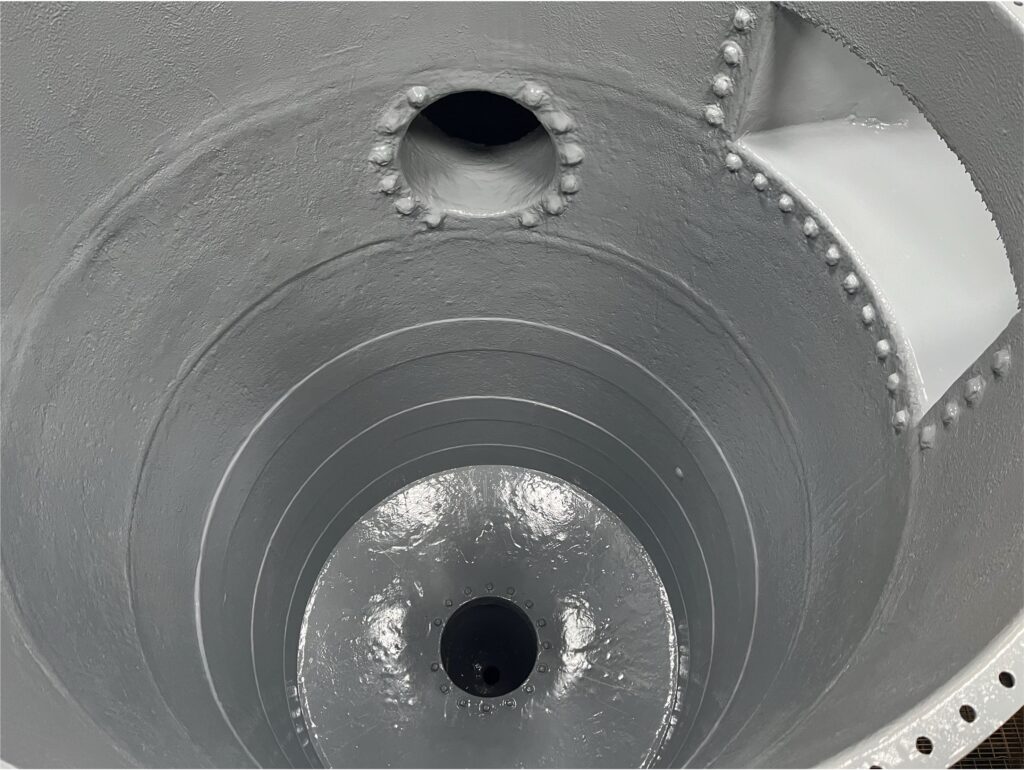

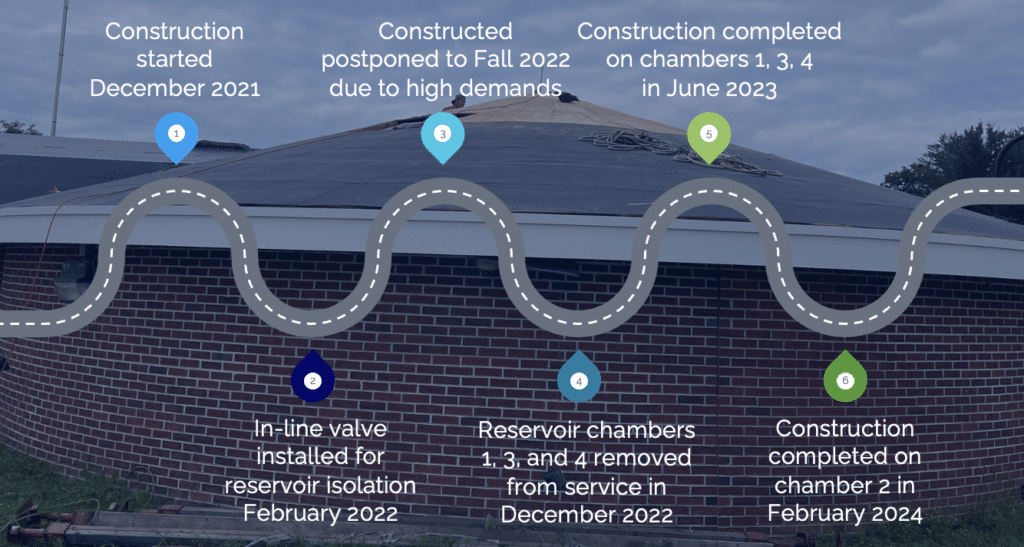

Following a review of the challenges, the design scope was revised. Final design and bidding on the project included standpipe rehabilitation, effluent valve and piping replacement, drain valve replacement, check valve replacement, and asphalt shingle roof replacement as well as the standpipe cover and man-way, interior lighting improvements, and instrumentation.

Following a review of the challenges, the design scope was revised. Final design and bidding on the project included standpipe rehabilitation, effluent valve and piping replacement, drain valve replacement, check valve replacement, and asphalt shingle roof replacement as well as the standpipe cover and man-way, interior lighting improvements, and instrumentation.