Tata & Howard designed and constructed the improvements to eliminate low and inadequate system pressures, construct a new source, pilot test filtration for manganese removal, design and construct required distribution system piping to connect the plant and storage tank with the system, design a new concrete storage tank, booster pump stations, and the filtration facility for manganese removal. The project was very successful and remains in great condition today.

Tata & Howard designed and constructed the improvements to eliminate low and inadequate system pressures, construct a new source, pilot test filtration for manganese removal, design and construct required distribution system piping to connect the plant and storage tank with the system, design a new concrete storage tank, booster pump stations, and the filtration facility for manganese removal. The project was very successful and remains in great condition today.

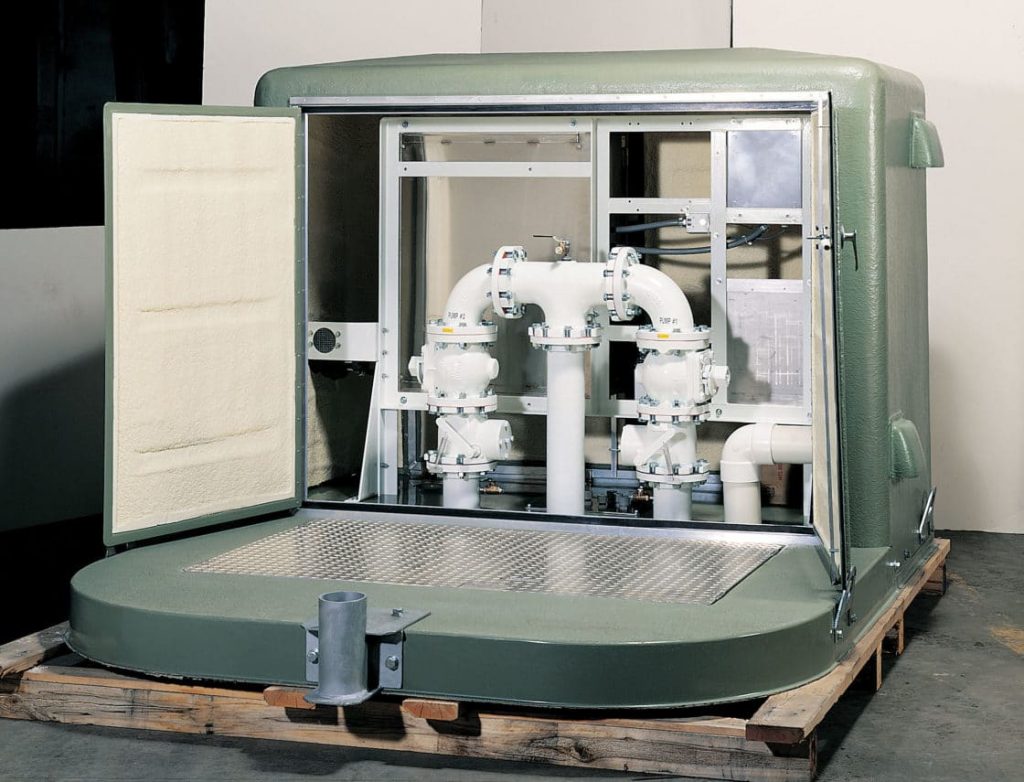

Services: Pump Stations

Maine Water Company Pump Station

Tata & Howard assisted Maine Water Company with mechanical, structural, and architectural design of a new high service zone booster pump station on Barra Road within the Biddeford-Saco water distribution system. The new pump station replaced the existing Alfred Road station, providing pumping capacity to meet current demands in a majority of the City of Biddeford as well as room for future expansion. Funding for the project was provided in part by the Maine Drinking Water Program State Revolving Fund (DWSRF).

Mechanical design for the project consisted of sizing and selection of three (3) centrifugal booster pumps, associated piping, and appurtenances. The pumps were sized with input from a hydraulic model of the system developed by Tata & Howard, and they were selected to maximize the available flow from a 16” cast iron pipe line that crosses the Maine Turnpike from the water system’s major storage reservoir. A pipe gallery was incorporated into the slab and foundation design as well as insulated concrete form (ICF) foundation walls. Per the Owner’s request, the architectural design used colors and materials similar to the other buildings within the surrounding commercial office park. Also, a gable roof canopy was added to the design (pictured below) to help shield the emergency backup generator from the elements. Precautions were taken to ensure proper air flow and ventilation was achieved to meet the requirements of the generator. Construction of the pump station was completed in 2015.

Shared Wastewater Treatment Facility, VT

CLIENT: The Towns of Canaan, VT and Stewartstown, NH

PROJECT: Shared Wastewater Treatment Facility

THE CHALLENGE: The existing wastewater treatment facility was 40 years old, costly to operate, and did not meet state and federal water quality standards. In addition, the Towns had very limited funds with which to upgrade the treatment facility.

THE SOLUTION: Tata & Howard helped the Towns secure a $2.412 million low-interest, long-term loan and $1.69 million in grant funds from the U.S. Department of Agriculture (USDA) Rural Development in order to build the new facility.

Tata & Howard, Inc. provided complete consulting engineering services for the construction of the wastewater treatment facility project which included the complete upgrade of four pump stations as well as the upgraded 0.185 mgd, 3-cell lagoon wastewater treatment facility. In addition, Tata & Howard’s St. Johnsbury, Vermont office, formerly Leach Engineering Consultants, provided full design services for all of the upgrades.

The Towns now enjoy a state-of-the-art, reliable wastewater treatment facility that meets the Effluent Discharge limits to the Connecticut River and provides for a more efficient treatment process. The new influent screening and grit removal processes extend the life of the treatment facility components. In addition, septage receiving provides for additional income and also provides service to the residents of the Towns that are not on public sewer.

The design included numerous energy-efficient features such as variable-frequency drives (VFDs) on aeration blowers, solar-powered lagoon mixers, a wood pellet boiler for heat, energy-efficient windows, and insulated concrete form (ICF) walls, resulting in a reduction in annual operation and maintenance costs. The pump stations were upgraded to eliminate operators entering below grade structures and to allow for future pump replacement that would be lower cost with it would be with the original centrifugal pumps.

PROGRESS: The project is complete, and the Towns celebrated the completion of their shared $4.12 million wastewater treatment facility with a ribbon-cutting ceremony in Canaan, VT.

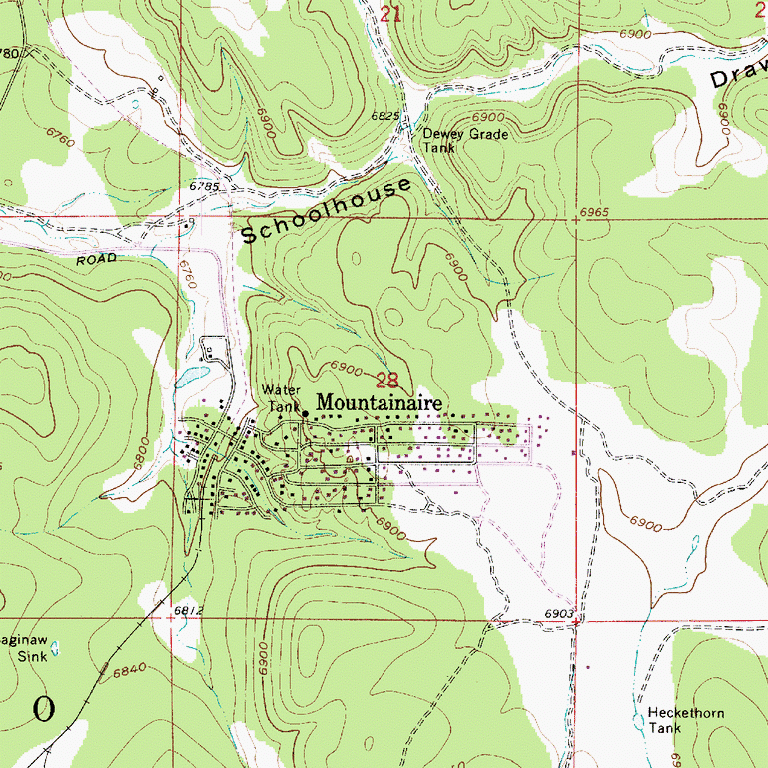

Asset Management-based Water Distribution System Study, Mountainaire, AZ

CLIENT: Ponderosa Utility Corporation, Arizona

PROJECT: Mountainaire asset management based water distribution system study to assist with prioritizing water system improvements

THE CHALLENGE: Mountainaire is a small water distribution system with limited manpower and revenue resources, and the operation and maintenance of the system is often reactive rather than proactive.

THE SOLUTION:

Tata & Howard successfully helped secure WIFA funding for the completion of the study which provides guidance to the PUC on how the system operates, what improvements are needed for efficient operation and continued maintenance of the system, and a prioritized approach to assist in funding and implementation of projects. This asset management based water distribution system study addresses undersized deteriorating water mains, above grade assets, and the energy efficiency of the pumping system. The study evaluates the system as a whole, based on above grade and below grade assets. Above grade assets are evaluated based on remaining useful life expectancy. Water mains are based on hydraulic capacity, criticality, and risk of failure. A hydraulic model was created for the study.

PROGRESS: Using the findings of the study, we are currently providing engineering services to evaluate flow and pressure requirements for the existing Kiowa Site booster pump station in order to construct a constant pressure pumping system to replace the existing booster pump and hydropnematic tank system that is old and failing.

Wastewater Pump Stations, Auburn, MA

CLIENT: Town of Auburn, Massachusetts Department of Public Works

PROJECT: Replacement of three existing wastewater pump stations

THE CHALLENGE: The sites were very small and restricted with high groundwater levels, and there were adjacent wetlands and private property. All three buildings were also very small and had other issues such as asbestos.

THE SOLUTION: We determined that the best course of action would be to demolish the buildings and convert the concrete dry pit that housed the pumping equipment into a wetwell for new, submersible pumps. The solution saved the Town hundreds of thousands of dollars.

PROGRESS: Tata & Howard provided the project design and will be putting the project out to bid this summer. We will also provide construction administration when construction begins in the fall.

8.4 mgd Water Treatment Plant Design, Permitting, Construction Administration, Falmouth, MA

THE CHALLENGE: More stringent USEPA and MassDEP regulations, including Stage 2 Disinfectants/Disinfection-by-Product Rule (S2 D/DBPR) and the Long Term 2 Enhanced Surface Water Treatment Rule (LT2ESWTR), resulted in the Town of Falmouth needing to make a decision on whether to construct a filtration facility in compliance with the SWTR or to upgrade disinfection processes only at the existing Long Pond Water Treatment Facility (LPWTF) to maintain the existing Filtration Waiver.

THE SOLUTION: Because the existing LPWTF utilized no filtration to remove bacteria, organics, and particulates, the water quality entering the distribution system was an ongoing concern with elevated turbidity and organics leading to seasonal color, taste, and odor complaints; elevated bacteria and concentrations; and elevated algae counts. In addition, the high doses of chlorine needed to maintain the disinfection residuals required for an unfiltered supply reacted with the organics in the raw water to form disinfection by-products. Therefore, the only viable option for the Town of Falmouth was a new water treatment plant. After evaluating 22 treatment processes and developing eight treatment alternatives for pilot testing, only one treatment process met all goals: Dissolved Air Flotation (DAF) clarification, intermediate ozone followed by filtration. This alternative also scored favorably on the benefit/cost analysis.

Tata & Howard provided design and construction services for the new Dissolved Air Flotation (DAF) facility with a design capacity of 8.4 million gallons per day (mgd) for the Long Pond surface water supply for the Town of Falmouth, MA. The water treatment plant (WTP) utilizes coagulation, mixing, flocculation, dissolved air flotation (DAF), dual media filtration including granular activated carbon (GAC) above sand, chemical feed systems, and an intermediate ozone feed. Building components include HVAC, plumbing, fire sprinkler, gas and electrical services. Other work included site work with exterior piping systems, exterior above and below ground tanks, sludge holding lagoons, construction of a garage, new raw water intake and pump station, directional drilling of raw water mains, and demolition of equipment and site piping at the existing water treatment facility.

As part of the project, Tata & Howard provided design and permitting of a new 8.4 mgd intake and raw water pump station (RWPS) for the WTP. The new intake and RWPS were constructed along the eastern shore of Long Pond and replaces the existing intake and Low Lift Pump Station. The new intake and RWPS includes a two-level intake consisting of two 8.4 mgd rated intake screens installed at elevations -3 feet below mean sea level (MSL) and -13 feet below MSL. The 36-inch HDPE intake pipeline connects the intake screens to the new RWPS located approximately 150 feet from the eastern shore of Long Pond. An air burst system was designed in the RWPS to provide a means for routine cleaning of the new intake screens.

An accelerated 11 month design and permitting schedule, followed by contractor prequalification, bidding, and award, were completed in time to qualify the Town for >$3M in principal forgiveness.

Design included the following:

• 300 Drawings

• 1,200 pages of Specifications

• SRF PEF application

• Monthly project meetings

• Coordination with Building Department

• Coordination with Board of Health

• Coordination with Town IT Department

• Coordination with Police and Fire Departments

• Coordination with Gas and Electric Utilities

Permits included the following:

• Wetlands Protection Act-Local Conservation Commission

• Board of Health

• Remediation General Permit (NPDES)

• Massachusetts General Permit

• Environmental Notification Form

• Massachusetts Historical Commission: Intensive Archaeological Survey including 200 test holes

• MassDEP Approval to Construct WTP: BRP WS 24

• DWSRF PAC

• 401 Water Quality Certification

• NHESP – Turtle Protection Plan

• Chapter 91 Waterways License

• U.S. Army Corps of Engineers General Permit The construction of the Long Pond Water Treatment Plant progressed on schedule and was completed in 2017. The plant included numerous sustainability and energy efficiency initiatives including the following:

The construction of the Long Pond Water Treatment Plant progressed on schedule and was completed in 2017. The plant included numerous sustainability and energy efficiency initiatives including the following:

- Recycling spent backwash water to head of plant and back into the treatment process, after it passes through a plate settler to remove solids.

- Recycling laboratory analyzer and filter influent piping gallery analyzer discharges back into the treatment process.

- Using filter-to-waste water after a filter backwash sequence as supply water for the next backwash, instead of using finished water for backwashing.

- Discharging cleaner supernatant water off the top of the lined lagoons to an unlined infiltration lagoon and back into the ground to minimize residuals.

- Use of local/native plants for landscaping, including an irrigation system using collected rainwater from roof drainage.

- Interior and exterior LED lighting fixtures.

- Variable Frequency Drives (VFDs) on HVAC equipment and process equipment motors.

The plant went online on October 18, 2017. The work was funded under the SRF program. The Long Pond Water Treatment Plant received an ENR New England 2017 Best Project Award in the Water/Environment category, and an Associated Builders & Contractors of Massachusetts Eagle Award in the Public Works – Environmental category.

For a drone video of the new water treatment plant taken by the general contractor, Methuen Construction, please see below:

Pump Stations, Wastewater Treatment Facility, and Force Main Design and Construction, Troy and Jay, VT

Tata & Howard provided engineering services for the evaluation, design, and construction of approximately five miles of pressure and gravity sewer to serve the mountain resort community of Jay, Vermont. The design also included the upgrade to air release structures for 4.5 miles of force main and upgrade of two pump stations, one a progressive cavity station.

In addition, Tata & Howard provided engineering services including planning, evaluation, design, permitting and construction services for the Troy-Jay wastewater treatment facility upgrade. The new headworks facility included screening and aerated grit removal and influent design for the force main/pressure sewer from the two towns and mountain resort. The treatment process was an SBR facility with tertiary filtration and UV disinfection for phosphorus removal.

District Water Treatment Facility, Transmission Mains, and Metering Station, Mattapoisett, MA

The MRVWD water treatment facility project was designed to treat water from eight wells belonging to the Towns of Fairhaven, Marion and Mattapoisett. The MRVWD facilities also include approximately 5 miles of raw water transmission mains between the wells and the water treatment facility, finished water transmission mains from the water treatment facility to the existing town transmission mains, six new 100 HP high lift pumps and control/metering stations. The existing pump stations were upgraded to pump water to the water treatment facility but operation of the pump stations will remain the responsibility of the individual towns.

The total cost of all project components was approximately $16.5 million, which was partially funded with a low interest SRF loan. By constructing a regional facility, the towns were able to save over $4.9 million in design and construction costs in comparison to individual treatment facilities.

Progressive Cavity Pump Stations, Ludlow, VT

Tata & Howard team members designed two high head progressive cavity pump stations for the Jackson Gore expansion project at Okemo Mountain. Each pump station was designed to fit in with the landscape and each had muffin monster grinders in front of the triplex pump arrangement. All process piping was stainless steel.

Industrial Park Interceptor Sewer and Pump Station, Medway, MA

Tata & Howard conducted an alternatives analysis for the collection and disposal of the 80,000 gpd of wastewater anticipated from the Medway Industrial Park at full build out. The study included investigations of on site treatment and subsurface effluent disposal, intermunicipal connections, and/or a pump station with force main and gravity sewer to provide sewers to the Industrial Park. Upon completion of the study, Tata & Howard was retained to design a new sewer interceptor and pump station to service the industrial park.

Tata & Howard completed the design of 18,000 linear feet of 8-inch and 18-inch diameter gravity interceptor sewer and a dedicated pump station with force main to service the Medway Industrial Park. The pump station is a wet well mounted suction lift pump station with a capacity of 500 gallons per minute and it includes a dedicated standby generator with automatic transfer switch.