Background

Hooksett Village Water Precinct (HVWP) Phase I Water Distribution and Storage Improvement Project is the first of three major drinking water components of the RTIA Tax Increment Financing (TIF) District economic development initiative sponsored by the Town of Hooksett. The project consisted of the construction of 1,800 linear feet of distribution system improvements in the Vista Drive area, a new 0.40 million gallon capacity glass-fused-to-steel tank, and 350 linear feet of associated transmission main from Daniel Webster Highway to Main Street.

The Precinct has been partnering with the Town, Sewer Commission, local businesses, committees, residents and area developers to encourage TIF-based infrastructure projects. TIF can be used to fund improvements that benefit the whole community by attracting new development, revitalizing blight, and/or enacting quality of life projects. This can significantly expand the tax base and provide more or easier access to services for residents with less financial impact.

Project Details

Hydraulic modeling studies completed in 2020 as part of the Precinct’s asset management program showed that distribution improvements were needed in the Vista Drive area to relieve a bottleneck that was critically restricting flow from the existing Quarry Tank and nearby wells. The Vista Drive area water main replacement/extension was listed as a Top Priority in the Precinct’s March 2021 Asset Management Plan Update. This area is the closest and primary source of water and fire protection for the TIF District, and a direct connection to the area is imperative to efficiently transmit water to the TIF District.

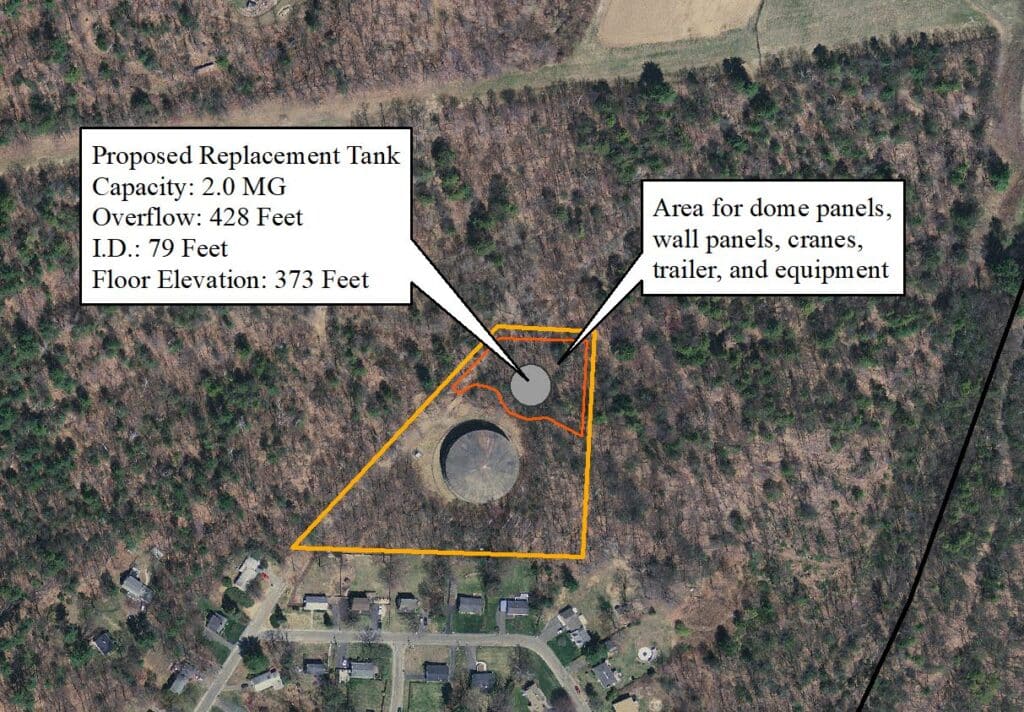

The Thompson Comer Tank is critical to water system hydraulics, not only for fire flow purposes but also for redundancy, emergency resiliency, and operational flexibility. It is inextricably linked to the operation of the Quarry Tank and the TIF District. Unfortunately, it had deteriorated to the point where it needed replacement. The new, slightly larger capacity replacement tank allowed the Quarry Tank to be taken offline as needed for O&M or emergencies; provide backup storage for the TIF district; allow the Quarry Tank to operate at 100% capacity; and improve overall energy efficiency by increasing off-peak operations.

Replacement of the existing Thompson Corner Tank also served as the permanent action plan to address a Significant Deficiency outlined by the New Hampshire Department of Environmental Services (NHDES) in October 2020. The deficiency identified was severe deterioration of the coating on the inside and outside of the tank. NHDES required that funding be authorized by March 2022 and a tank construction contract be awarded by October 2022.

Replacement of the existing Thompson Corner Tank also served as the permanent action plan to address a Significant Deficiency outlined by the New Hampshire Department of Environmental Services (NHDES) in October 2020. The deficiency identified was severe deterioration of the coating on the inside and outside of the tank. NHDES required that funding be authorized by March 2022 and a tank construction contract be awarded by October 2022.

The cost to replace the Thompson Corner tank and install the Vista Drive area water main and associated transmission main was $2,464,000 and was funded by 2021-22 NH Drinking Water & Groundwater Trust Fund (DWGTF) and NHDES American Rescue Plan Act (ARPA) Funds.

And the Winner Is…

And the Winner Is…

Each fall, the Granite State Rural Water Association holds a drinking water taste test at its Annual Operator Field Day and Exhibit. In fall 2024, just after the completion of the project, HVWP had the honor of winning the contest!

Since Hooksett Village Water Precinct won the water taste test contest at Granite State Rural Water Association Operator Field Day this fall, they were able to represent New Hampshire in the National Rural Water Association’s The Great American Water Taste Test, where they won second place out of 43 systems in the National Rural Water Association’s “The Great American Water Taste Test” in Washington D. C. in February 2025. Mike Heidorn, P.G., Superintendent, represented HVWP and accepted the award.

We are very proud of the collaboration and efforts of both HVWP and the Tata & Howard team for the incredible success of our partnership.

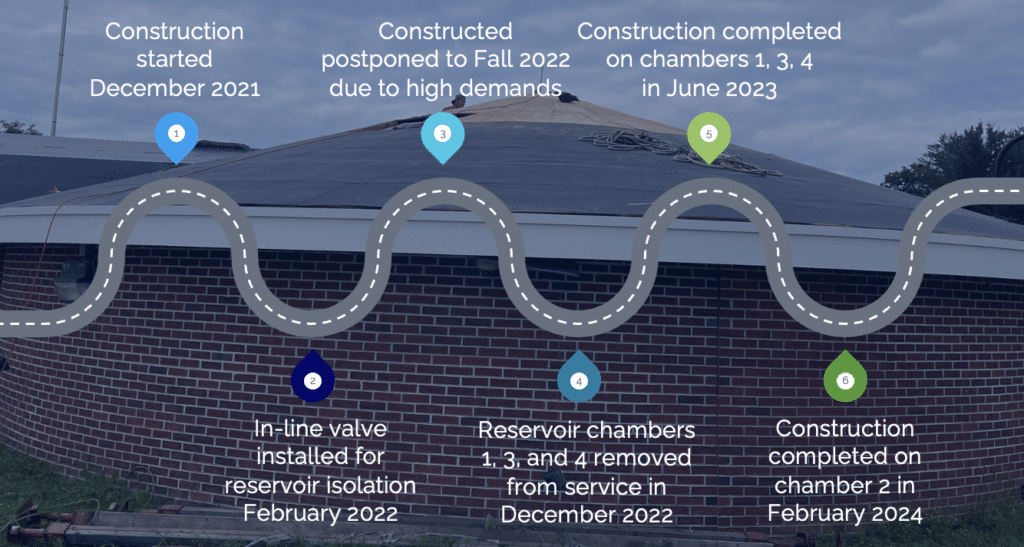

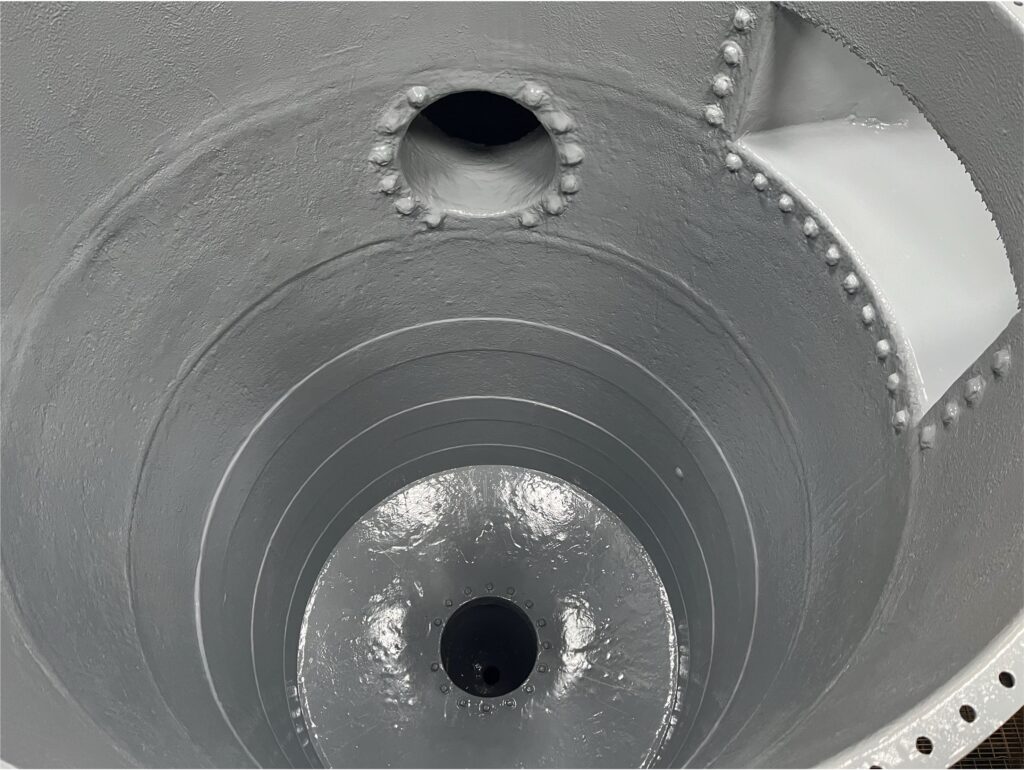

Following a review of the challenges, the design scope was revised. Final design and bidding on the project included standpipe rehabilitation, effluent valve and piping replacement, drain valve replacement, check valve replacement, and asphalt shingle roof replacement as well as the standpipe cover and man-way, interior lighting improvements, and instrumentation.

Following a review of the challenges, the design scope was revised. Final design and bidding on the project included standpipe rehabilitation, effluent valve and piping replacement, drain valve replacement, check valve replacement, and asphalt shingle roof replacement as well as the standpipe cover and man-way, interior lighting improvements, and instrumentation.

Hydraulic impact was also studied. Pressure decreased 2-4 PSI depending on which sources were running, and the available fire flow decreased up to 600 gpm, but was limited to the area around the tank which is mostly residential. Resultant flows were sufficient for the residential area.

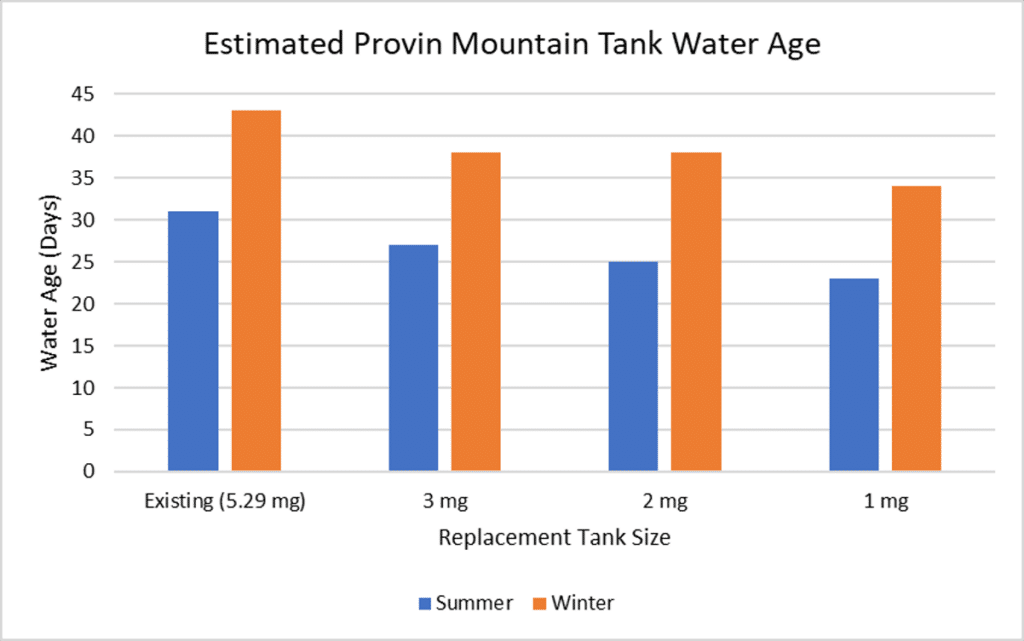

Hydraulic impact was also studied. Pressure decreased 2-4 PSI depending on which sources were running, and the available fire flow decreased up to 600 gpm, but was limited to the area around the tank which is mostly residential. Resultant flows were sufficient for the residential area. While storage and hydraulics showed that the tank was not needed, it was determined that there would be significant lack of fire protection in much of the system if the Sackett Tank was offline for repairs or other issues in addition to elimination of the Provin Mountain Tank. Due to the lack of fire protection under this scenario, it was ultimately recommended to replace the tank.

While storage and hydraulics showed that the tank was not needed, it was determined that there would be significant lack of fire protection in much of the system if the Sackett Tank was offline for repairs or other issues in addition to elimination of the Provin Mountain Tank. Due to the lack of fire protection under this scenario, it was ultimately recommended to replace the tank.

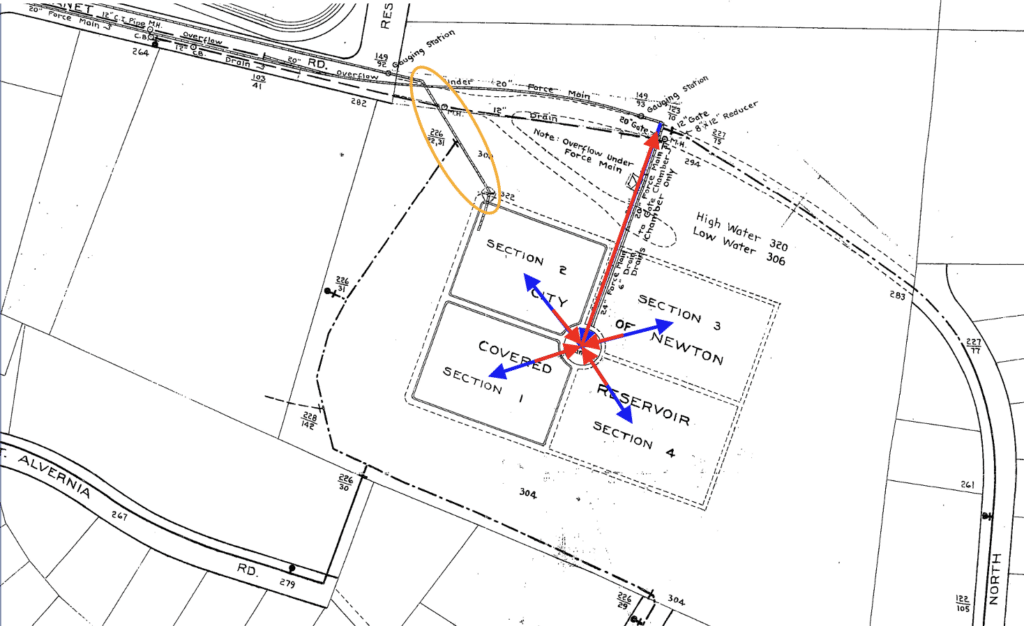

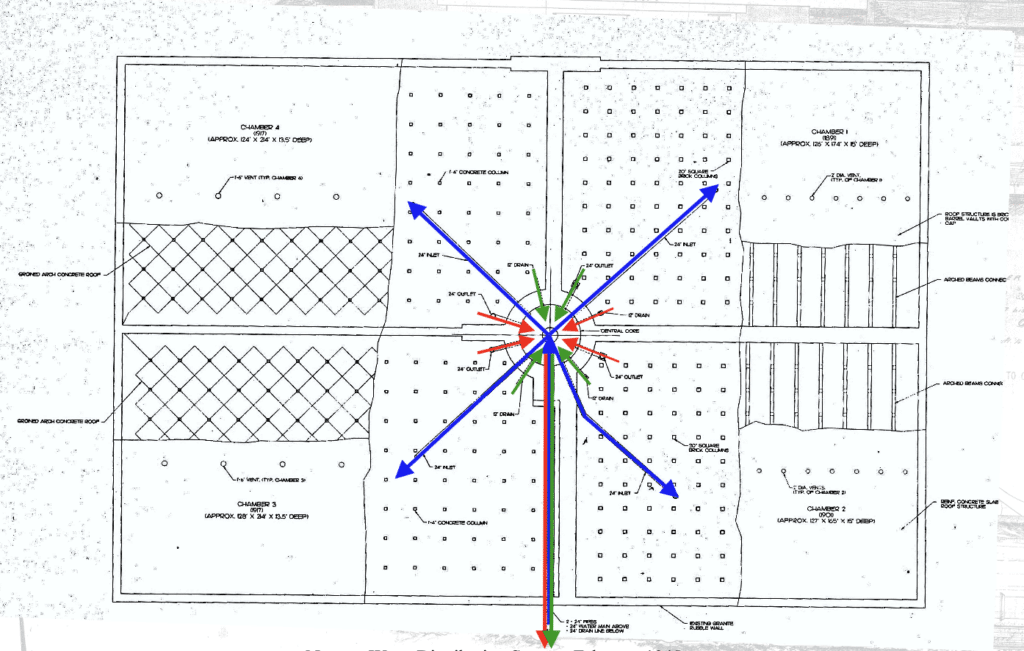

Tata & Howard designed and constructed the improvements to eliminate low and inadequate system pressures, construct a new source, pilot test filtration for manganese removal, design and construct required distribution system piping to connect the plant and storage tank with the system, design a new concrete storage tank, booster pump stations, and the filtration facility for manganese removal. The project was very successful and remains in great condition today.

Tata & Howard designed and constructed the improvements to eliminate low and inadequate system pressures, construct a new source, pilot test filtration for manganese removal, design and construct required distribution system piping to connect the plant and storage tank with the system, design a new concrete storage tank, booster pump stations, and the filtration facility for manganese removal. The project was very successful and remains in great condition today.