Tata & Howard is providing all engineering support services related to the operation of and modifications to the Town’s wastewater collection, pumping, and treatment systems including preparation of a Comprehensive Wastewater Management Plan (CWMP) and preparation of a comprehensive Infiltration/Inflow (I/I) Evaluation. In addition, we are providing all ongoing support services related to the preparation of a Capacity, Management, Operations, and Maintenance (CMOM) program to meet US EPA’s regulations as well as technical assistance on the renewal of the Town’s NPDES permit. Included in this project is the preparation of the Town’s I/I control plan and all annual updates, preparation of the Town’s sewer use regulations and standard specifications for sewer construction, review of plans for all private developments, and review of all applications for industrial wastewater connection permits and pretreatment reports.

All services related to I/I identification, evaluation, and removal performed on the Milford’s sewer system, which consists of approximately 100 miles of interceptor sewers and mains, including an innovative sump pump removal program, has resulted in a dramatic reduction in extraneous flow to the system.

Tata & Howard conducted an energy efficiency study on the aeration blowers and pumps at the Rio and Wildcat Hill treatment plants. The testing showed that modifications to these systems have the potential to save the City approximately $250,000 in annual electrical costs and $445,000 in APS rebate funds for the modifications. Pumping systems had efficiencies as low as 20%. Pumps and blowers were oversized to meet peak and future demands but not efficient at low flows or off peak flows. Energy usage per million gallons treated of 2,170 KWH/MG with cogeneration and 2,804 KWH/MG at the Rio plant, with national average usage of 1,750 KWH/MG.

The project included the testing of blowers and pumps at two reclaimed water plants; review of all the wells, pressure reducing valves, boosters, and splits for energy savings; further evaluation of the turbo blowers and barscreens; and an evaluation of the replacement of the biogas piping for use in cogeneration.

Presentation:

Abstract: In Arizona, the Arizona Public Service (APS) estimates that water systems use 1/7th of all the power used in the State. From the APS testing program, it is estimated that 60 to 70 percent of all pumps have tested below industry standards or changes in operations are needed to operate more efficient. This presentation discusses the findings associated with energy studies completed for a small water supply system (Kachina Village Improvement District) and for a large system (City of Flagstaff, Arizona). The studies show that any water and/or wastewater system, regardless of size can benefit from an energy audit. The studies resulted in significant annual savings, potential rebates from APS to offset replacement costs, high return on investments, while promoting green initiatives.

SaveSave

SaveSave

Tata & Howard is working on a five year infiltration/inflow (I/I) control plan for Cherry Valley Sewer District (CVSD) in Leicester, Massachusetts. The program consists of flow monitoring, field investigation, and rehabilitation to the wastewater collection system.

In year one of the program, continuous flow, groundwater, and rainfall monitoring took place in the spring to collect data for program analysis. Simultaneous to the monitoring, manhole inspections were performed to assess I/I potential from manholes.

Year two consisted of a data analysis of the flow monitoring results of year one. The results of this data analysis from the I/I control plan provided guidance to moving forward with I/I investigation.

Field investigation commenced in year three of the program with smoke testing being completed throughout the collection system. To follow up with results from the manhole inspection, manhole rehabilitation was performed on manholes in which I/I was evident.

Year four focused on field investigations. A large section of the collection system was inspected via closed circuit television (CCTV). Follow up building inspections were also performed in areas where sump pump connections were suspected to be an issue. Year four also focused on system operation and maintenance. Documents were created for CVSD to focus on operations and maintenance of the system, and specifically for the manhole which houses the system flow meter into Worcester.

Year five is consisting of further CCTV investigation and a final report to summarize the project and provide recommendations on moving forward with investigations. Future work is anticipated to focus around GIS aspects of the system and working with CVSD to maintain records and reduce I/I by being proactive with investigation and maintenance.

Tata & Howard conducted an alternatives analysis for the collection and disposal of the 80,000 gpd of wastewater anticipated from the Medway Industrial Park at full build out. The study included investigations of on site treatment and subsurface effluent disposal, intermunicipal connections, and/or a pump station with force main and gravity sewer to provide sewers to the Industrial Park. Upon completion of the study, Tata & Howard was retained to design a new sewer interceptor and pump station to service the industrial park.

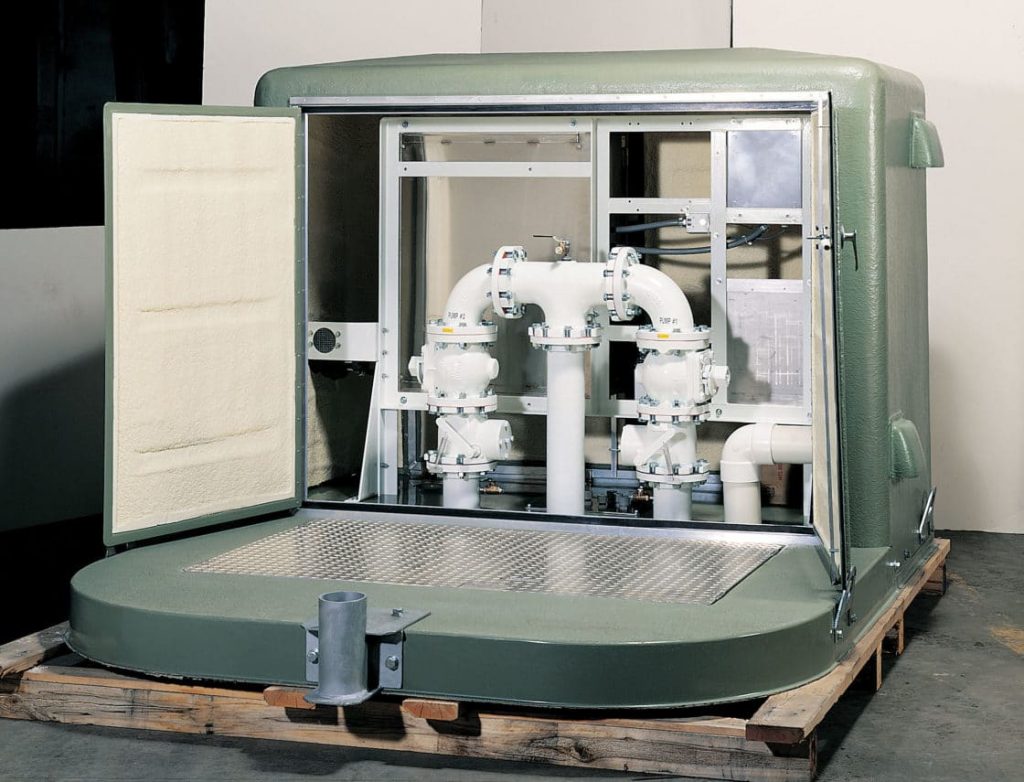

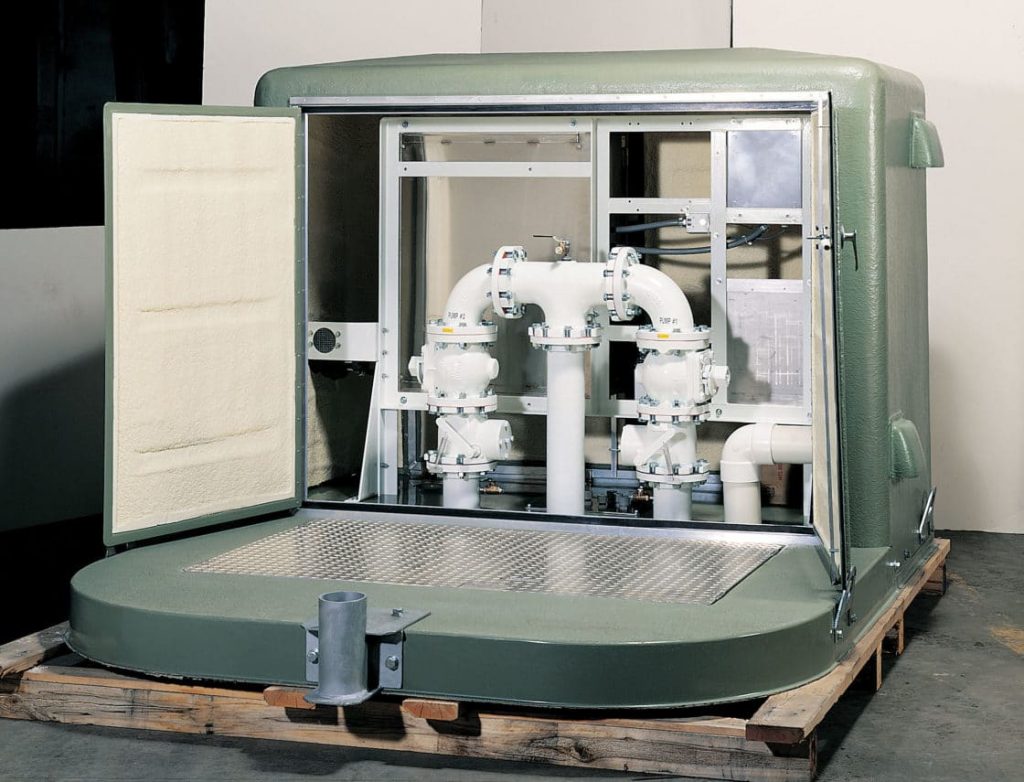

Tata & Howard completed the design of 18,000 linear feet of 8-inch and 18-inch diameter gravity interceptor sewer and a dedicated pump station with force main to service the Medway Industrial Park. The pump station is a wet well mounted suction lift pump station with a capacity of 500 gallons per minute and it includes a dedicated standby generator with automatic transfer switch.

Tata & Howard prepared a wastewater treatment and disposal alternative analysis for the Town of Ayer. The analysis evaluated alternative plans for treatment and disposal of wastewater utilizing the Town’s existing wastewater treatment facility, a proposed regional wastewater treatment facility, or a combination of both facilities.

The alternative analysis estimated the wastewater flows and loadings, assessed the condition and capacity of the existing plant unit processes, and recommended improvements to meet the future service needs over the next 20 years. Tata & Howard designed upgrades to the existing main wastewater pump station which pumps the entire volume of wastewater generated in Ayer.

In addition to the overall rehabilitation of the pump station, Tata & Howard designed the addition of new pumping facilities to divert wastewater to the nearby regional wastewater treatment facility at the former Fort Devens, now managed by Mass Development. The main wastewater pump station has a peak capacity of 4.0 mgd and includes four wastewater pumps with a capacity of 2,800 gpm. The upgrades included new variable frequency drives for the pumps and new SCADA.

The Town of Barre retained Tata & Howard to evaluate their existing wastewater treatment facility. Tata & Howard recommended a three phase upgrade program in order to reduce the initial impact of the construction cost on the sewer use rates. Included in the upgrade program was the design and construction of a submersible pump station that lifts the raw wastewater from an equalization tank to the biological treatment process. The pump station has a capacity of 1.2 mgd and includes variable frequency drives. The pumping station is controlled by a new SCADA system at the wastewater treatment facility. Tata & Howard also designed 8,000 linear feet of collection system sewers in the Worcester Road area of town. The project also included 500 linear feet of force main and a wet well mounted pump station. The pump station has a capacity of 200 gpm.

Tata & Howard provided engineering services associated with sewer improvements including evaluation, design, and construction of 3,500 linear feet of interceptor sewer, 2,500 linear feet of force mains, and three pump stations. In addition, Tata & Howard provided design and construction of 5,000 linear feet of interceptor sewer, 4,000 linear feet of gravity sewer including a river crossing, and a pump station. Tata & Howard also provided design and construction services for three new wastewater pump stations. The pump station scope included upgrading of one pump station and the design of two other pump stations. One of the pump stations is a suction lift station while the other two are submersible stations.

Tata & Howard provided engineering services including wastewater consulting services to develop a plan for the removal of existing inflow and infiltration (I/I) from the Town of Pembroke’s sewer collection system. The purpose of this evaluation was to review pertinent available information provided by the Town, develop a draft plan of approach to reduce I/I within the system over time and as funds are appropriated, develop a prioritized schedule for further investigations of I/I, and establish a protocol for the documentation of I/I removed from the collection system.

Tata & Howard provided engineering services for the evaluation, permitting, design, and construction of five wastewater pump stations. The pump stations included a new triplex pump station with valve structure. The wastewater treatment plant upgrade was in addition to the pump stations. The other four pump stations consisted of a new, completely relocated pump station and the upgrading of three other dry pit wet pit stations to include generators and controls for telemetry. The pump station design included a plan for maintaining operations of the stations throughout construction, which was completed in the fall of 2014.

Tata & Howard team members provided engineering services to The Dexter Utility District to evaluate their existing wastewater treatment facility and to provide wastewater treatment facility design. It was recommended that a phased approach to upgrade the facility be utilized in order to reduce the initial impact on the sewer user rates.

The first phase of the improvements combined improvements which would improve the reliability and obtain energy savings with cleaning and disposing of sludge for the first time from their 25 year old facility. This approach allowed for a grant loan financing package to be utilized. The first phase facility upgrade included replacing a leaking single air header main with two individual air headers, replacing course bubble diffusers with fine bubble membrane diffusers, replacing three 25 year old blowers with new blowers with variable speed drives. The speed of the new blowers is controlled by a PID loop using dissolved oxygen analyzers, to maintain optimum treatment and minimize energy consumption. These improvements have reduced the energy consumption at the wastewater treatment facility by more than 50 percent.

SaveSave

SaveSave