Tata & Howard, Inc. conducted an energy audit of the City of Flagstaff’s Water System. The purpose of this energy audit was to identify energy conservation opportunities that would provide annual and life cycle power cost savings for the City of 66,600 people. Tata & Howard provided upgrades that would raise efficiency, resulting in significant annual savings. In addition, the upgrades qualified for a rebate through APS, resulting in an average payback of less than three years.

Tag: wastewater

Tata & Howard, Inc. participates in Rally for the Jimmy Fund

Tata & Howard, Inc. participates in Rally for the Jimmy Fund

Charitable event celebrates over $4 million in donations to Dana-Farber Cancer Institute since its 2006 inception

MARLBOROUGH, MA, April 14, 2015 – Tata & Howard, Inc., a leading innovator in water, wastewater, stormwater, and hazardous waste engineering solutions, participated in the Rally for the Jimmy Fund yesterday. The Rally encourages people to wear Red Sox gear on Opening Day at Fenway Park, which fell on Monday, April 13 this year, in exchange for a donation to the Jimmy Fund. Tata & Howard team members were happy to donate to the Jimmy Fund while enjoying a casual Red Sox day at the office.

The Rally and the Jimmy Fund

The Red Sox organization has partnered with the Jimmy Fund since 1953, and the Rally for the Jimmy Fund is just one of many Red Sox/Jimmy Fund initiatives. Monies raised through the Rally help ease the patient experience and allow future discoveries to revolutionize cancer treatments around the world. Eighty-nine cents of every dollar raised by the Jimmy Fund and Dana-Farber goes directly to Dana-Farber Cancer Institute, which received the highest possible ranking of four stars by Charity Navigator, America’s largest independent evaluation of non-profit organizations. Since its inception in 2006, Rally for the Jimmy Fund has raised over $4 million.

“We are thrilled to be part of such a worthwhile charity,” stated Donald J. Tata, P.E., President of Tata & Howard.” Through participation in other local events such as the PanMass Challenge and the Mass Dash for the Jimmy Fund, Tata & Howard team members raise funds for the Jimmy Fund throughout the year. The Rally for the Jimmy Fund was yet another way for us to support Dana-Farber and cancer research.”

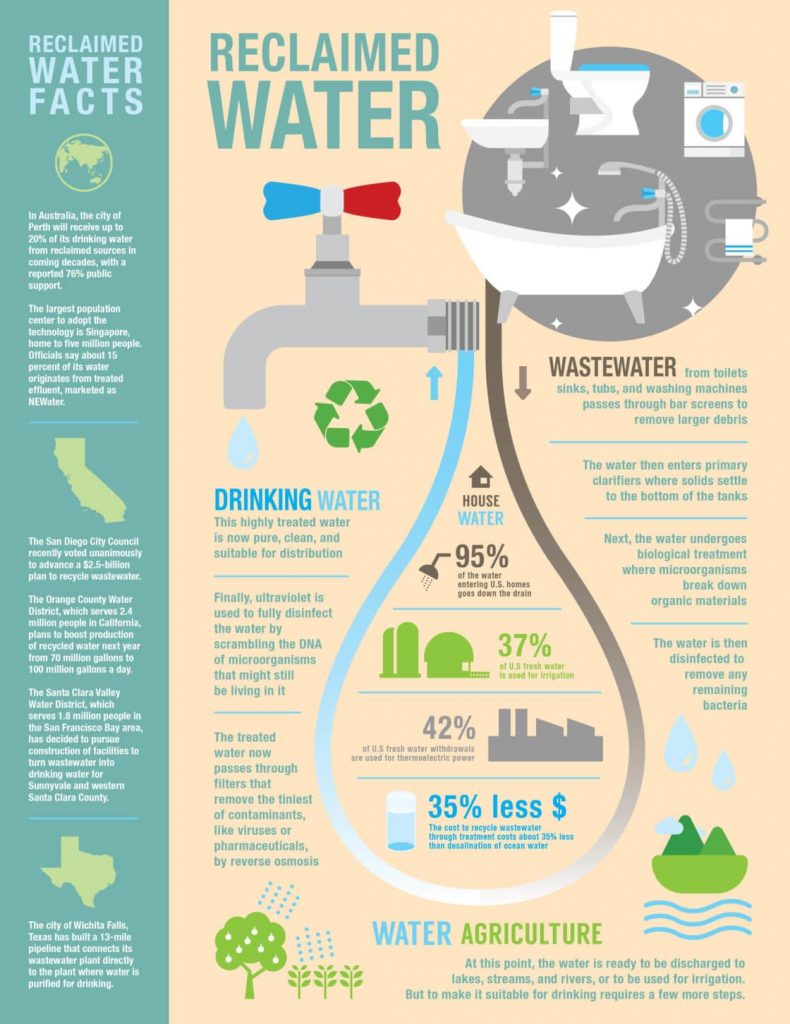

Reclaimed Water — From Toilet to Tap Infographic

Reclaimed Water — From Toilet to Tap Infographic

Would you drink water that was once used in the toilet? Chances are you just gave an emphatic “no”. But what if that water is actually so highly treated and processed that it is actually cleaner than the water currently coming out of most people’s taps? For the overwhelming majority of people, their answer is still that same emphatic “no”. Commonly referred to as the “yuck factor”, the idea of drinking recycled wastewater is simply too much for the human mind to overcome. However, climate change, population growth, and overuse have strained freshwater resources, and people may just need to change their way of thinking.

A Limited and Precious Resource

In the developed world, fresh water is taken for granted, when it is in fact a limited resource. About 97% of the Earth’s water is saltwater. More than two-thirds of the remaining fresh water is frozen in glaciers, which leaves less than 1% of the Earth’s water as fresh and available. In addition, the global population is growing astronomically at the same time that historic droughts plague Australia and the United States, two of the world’s largest water consumers. Los Angeles, Las Vegas, and Phoenix are three of the driest cities in America, and they are also experiencing some of the highest rates of population growth. Conservation isn’t working, water supplies are running dry, and the most drought-stricken areas are looking, albeit reluctantly, to reclaimed wastewater.

“When we talk about reclaimed wastewater, we’re not talking about something that’s simply at the level of convenience,” says David Feldman, a political scientist at the University of California at Irvine. “We’re really dealing with an issue that is going to be affecting every country, every society.” Avoiding future clashes over water, he says, will mean having to drink treated wastewater.

There is no doubt that we all drink water that has passed through a human or animal at some point. The Earth’s water is a finite resource that constantly cycles, and treated wastewater is frequently discharged into lakes and rivers that supply drinking water. But while most people have no problem drinking water from sources that have been augmented with treated wastewater, the thought of taking water flushed down the toilet and directly repurposing it into drinking water is a bit tough to, well…swallow.

Reclaimed Water Usage Today

Singapore is arguably the world’s most well-known and successful wastewater recycler. Their reclaimed water, branded as NEWater, supplies 15 percent of the population’s water, and is considered cleaner and purer than any tap water. In Australia, the city of Perth will receive up to 20% of its drinking water from reclaimed sources in coming decades. And, through public education and marketing efforts, the Perth project has a reported 76% public support.

Similar efforts are also in progress in the U.S. In San Diego, a 2004 survey indicated that 63 percent of county residents opposed adding treated wastewater to the drinking water supply. But as the drought has worsened and the population has grown, the city is running out of options. Therefore, the San Diego County Water Authority turned to community and environmental groups to help educate the public about the safety of recycled water, and in November, 2014, the San Diego City Council voted unanimously to advance a $2.5 billion plan to recycle wastewater. What’s more, recent polls show that opposition to reclaimed water has fallen to only 25 percent.

The Orange County Water District, which serves 2.4 million people in California, plans to boost production of recycled water next year from 70 million to 100 million gallons per day. And, the Santa Clara Valley Water District, which serves 1.8 million people in the San Francisco Bay area, has decided to pursue construction of facilities to turn wastewater into drinking water for Sunnyvale and western Santa Clara County.

In Texas, the drought-stricken city of Wichita Falls has built a 13-mile pipeline that connects its wastewater plant directly to the plant where water is purified for drinking. In addition, the Colorado River Municipal Water District has been piping treated effluent from a wastewater treatment plant in Big Spring, Texas to a drinking-water plant that serves Big Spring, Snyder, Midland and Odessa for more than a year.

Explaining the Treatment Process

Education is the key to making recycled wastewater — or reclaimed water — more palatable, and explaining the process of water treatment is the most critical step in changing public opinion. When a person flushes a toilet, wastewater is carried through sewers to a municipal wastewater treatment plant. There, large solid material is separated from liquid with grates or bar screens. Next, the wastewater enters a settling tank where smaller solids fall out of solution and oils rise to the surface where they are skimmed off. The wastewater next moves to an aeration tank, where microbes feed on the waste and break it down. The water is then disinfected with chemicals such as bleach and chlorine. After an additional settling step, the treated water undergoes reverse osmosis where it passes through filters that remove even the tiniest of contaminants, like viruses or pharmaceuticals. Finally, the water is treated with ultraviolet light to fully disinfect the water by scrambling the DNA of anything that might still be living in it. This highly treated water is actually cleaner and more pure than most water currently pouring from our taps.

Education is the key to making recycled wastewater — or reclaimed water — more palatable, and explaining the process of water treatment is the most critical step in changing public opinion. When a person flushes a toilet, wastewater is carried through sewers to a municipal wastewater treatment plant. There, large solid material is separated from liquid with grates or bar screens. Next, the wastewater enters a settling tank where smaller solids fall out of solution and oils rise to the surface where they are skimmed off. The wastewater next moves to an aeration tank, where microbes feed on the waste and break it down. The water is then disinfected with chemicals such as bleach and chlorine. After an additional settling step, the treated water undergoes reverse osmosis where it passes through filters that remove even the tiniest of contaminants, like viruses or pharmaceuticals. Finally, the water is treated with ultraviolet light to fully disinfect the water by scrambling the DNA of anything that might still be living in it. This highly treated water is actually cleaner and more pure than most water currently pouring from our taps.

Getting Past the “Yuck Factor”

Technologies being developed today will make wastewater recycling more efficient and less expensive, but changing people’s opinion of drinking “toilet to tap” is the bigger challenge, experts say. Studies show that human beings naturally possess a strong aversion to consuming any food or drink that could possibly contain pathogens. However, there are some steps that can be taken to change public opinion. Adding an extra step in the treatment process, like discharging treated wastewater to a river that then carries it from one city to a drinking water treatment plant in another city, can eliminate the mental stigma. Discharging wastewater into rivers and aquifers instead of water pipes is more expensive but may be useful for gaining public acceptance. Public information campaigns that emphasize economic benefits, protection of U.S. water supplies, and personal safety can also increase public support. In addition, endorsement by a trusted group, like the Surfrider Foundation who helped raise support for wastewater reuse in San Diego, can also reduce stigma.

Technologies being developed today will make wastewater recycling more efficient and less expensive, but changing people’s opinion of drinking “toilet to tap” is the bigger challenge, experts say. Studies show that human beings naturally possess a strong aversion to consuming any food or drink that could possibly contain pathogens. However, there are some steps that can be taken to change public opinion. Adding an extra step in the treatment process, like discharging treated wastewater to a river that then carries it from one city to a drinking water treatment plant in another city, can eliminate the mental stigma. Discharging wastewater into rivers and aquifers instead of water pipes is more expensive but may be useful for gaining public acceptance. Public information campaigns that emphasize economic benefits, protection of U.S. water supplies, and personal safety can also increase public support. In addition, endorsement by a trusted group, like the Surfrider Foundation who helped raise support for wastewater reuse in San Diego, can also reduce stigma.

Running Out of Options

Population growth, depleted resources, climate change, and severe drought have all impacted our water supply. Reports have stated that California will run out of water by 2016. In Las Vegas, Lake Mead has shrunk to 60% of the size it was two decades ago. Wichita Falls, Texas is under a Stage 5 Drought Catastrophe. Conservation efforts have failed, our water supplies are drying up, and municipalities do not have the resources to supply enough water to the public. While the thought of drinking treated wastewater may be repugnant, it is only a matter of time before we run out of options. Notes Feldman, “I think between climate change, increased urbanization, and growing demands for food and energy, there’s really no way around reusing wastewater.” And unless something drastically changes, repurposing wastewater will not only be accepted in the future, but commonplace.

Roald Haestad, Inc. Staff Join the Tata & Howard Team

Roald Haestad, Inc. staff join the Tata & Howard team

Tata & Howard enhances its water, wastewater, and stormwater consulting engineering services and adds dam engineering services by acquiring the assets of Connecticut-based consulting firm Roald Haestad, Inc.

WATERBURY, CT, August 27, 2014 – Tata & Howard, Inc., a leading innovator in water, wastewater, stormwater, and hazardous waste engineering solutions, announced today that it has acquired the assets of Roald Haestad, Inc., (RHI) a civil engineering consulting firm located in Waterbury, CT. Founded in 1971, RHI is a full service civil engineering firm providing services in water supply, stormwater, water distribution systems, and wastewater collection systems, with targeted expertise in safe yields and dam engineering. Throughout its 43-year history, RHI has built a solid reputation for providing superior design and engineering services along with exceptional client relations. Additional services include roadways, permitting, funding assistance, GIS, and surveying, including GPS, floodplain mapping, and bathymetric surveys.

“Our acquisition of RHI complements our existing engineering consultant offerings by allowing us to provide additional civil engineering services, including dam engineering, surveying, and streamflow release analysis,” noted Donald J. Tata, P.E., co-founder and President of Tata & Howard, Inc. “We intend to provide the same high-level service to the clients of RHI, and are excited about the wide variety of options we can now offer to our existing and new clients,” explains Tata.

To provide the best possible transition for current RHI clients, Tata & Howard will continue operations from Haestad’s Waterbury location, along with existing RHI employees. “The acquisition significantly adds to our talent base and also expands our geographic presence in New England,” Tata commented. “RHI employees bring decades of solid engineering experience to the table, and we are enthusiastic to have them on the Tata & Howard team.”

Ronald G. Litke, P.E., President of RHI, will be retiring and remain available on a limited basis, He commented, “In looking to the future, our key concerns were our clients and our employees” he commented. “By joining Tata & Howard, we have ensured seamless transition and exceptional service for our clients, along with a stable and bright future for our employees. It’s a win-win situation.”

Alternative Toilet Technology – What’s the Stink About?

In America, we use about 30% of our nation’s drinking water supply – fresh, treated, clean water – to flush our toilets. We are suffering from one of the worst droughts in recent history, and our nation is literally running out of water. We need to conserve the water we have, and the most efficient way to accomplish this task is through alternative toilet technology. Luckily, engineers work every day designing these eco-conscious toilets, some of which we will showcase here.

In America, we use about 30% of our nation’s drinking water supply – fresh, treated, clean water – to flush our toilets. We are suffering from one of the worst droughts in recent history, and our nation is literally running out of water. We need to conserve the water we have, and the most efficient way to accomplish this task is through alternative toilet technology. Luckily, engineers work every day designing these eco-conscious toilets, some of which we will showcase here.

High Efficiency Toilets

Before we get into the newer technology of High Efficiency Toilets (HET), let’s first take a look at the traditional toilet. The old-fashioned Gravity Feed toilet is certainly reliable. It’s been around for decades and gets the job done. With each flush, a valve opens up and gravity forces water down a tunnel, while the resulting pressure forces waste down another, lower, tunnel called a trapway. However, until recently, this traditional design has used 3.5 gallons per flush (GPF) or more, some models using up to 5 GPF. Once the 1.6 GPF restrictions took effect, the Gravity Feed toilet didn’t perform quite so well, often clogging and requiring multiple flushes – which defeats the purpose of a low-flow toilet in the first place. As a result, engineers started working on water efficient toilets, commonly referred to as HETs. HETs are designed to work with existing plumbing and, while they still use water, they use significantly less water than traditional toilets.

Dual-Flush Toilets

A step up in effectiveness is the Dual-Flush design. This high efficiency toilet earns the name by offering two ways to eliminate waste, usually by the use of two separate buttons to press. Press one and only about 1.3 gallons is released, which works fine for removing liquid waste. Press the second (or both buttons together in some instances) and 1.6 gallons is released.

A step up in effectiveness is the Dual-Flush design. This high efficiency toilet earns the name by offering two ways to eliminate waste, usually by the use of two separate buttons to press. Press one and only about 1.3 gallons is released, which works fine for removing liquid waste. Press the second (or both buttons together in some instances) and 1.6 gallons is released.

Other models vary the technique. Some use as little as 0.8 GPF to 1.1 GPF. Some allow for a more traditional-style handle but one that can also be pulled up rather than just pushed down. Move it one way and you get the partial flush; the other way releases the larger amount of water.

Pressure Assist Toilets

The next step up, in the sense of efficiency and oomph, is the Pressure Assist design. Here, the toilet doesn’t rely solely on gravity (as do both the Gravity Feed and many Dual-Flush models) but adds artificially generated pressure. Typically, that pressure is supplied by a plastic or metal canister that holds air. With each flush, the air adds additional pressure to that supplied by the force of gravity. And the combination is impressive: they can typically handle 40 feet of toilet paper in a single flush without jamming. Solid human waste is no challenge to these units.

Still, they have a downside. They don’t have motors that create the pressure and they put extra stress on your pipes. Those two facts imply two more: your home water system must supply adequate pressure in the first place and your pipes must be able to withstand the flush pressure. Fortunately, most homes satisfy those requirements, especially those built in the past 40 years.

Power Assist Toilets

A less-common variation on the HET theme is the Power Assist design. It actually incorporates a pump that forces water at higher velocity than is possible from a gravity feed or simple pressure assist method. The flush volumes are usually between one and 1.3 GPF, so they satisfy the legal restrictions.

However, this type typically requires a 120-volt electrical source to power the motor that drives the pump. While they’re safe, many consumers don’t feel comfortable having a water device like a toilet so directly connected to an electrical supply. They’re also generally much more expensive and usually overkill for homeowners. As a consequence, they’re more often found in commercial establishments and even there they are relatively rare.

Waterless Toilets

With our nation’s water crisis looming, waterless toilets make the most sense, because they use literally no water. And the even better news about waterless toilets is that, besides the waterless urinal, they don’t connect to any plumbing or infrastructure, which can save thousands in new construction and on water and sewer bills. But is waterless toilet technology advanced enough to be viable in the typical household or commercial setting? Let’s take a look.

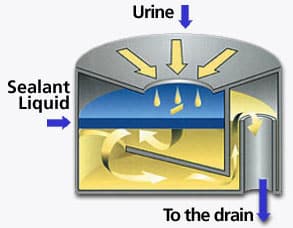

Waterless Urinals

Waterless urinals have gained in popularity and are becoming more widely used in commercial settings, even being approved by the plumbing code since 2006. They use gravity to force urine down through a trap that contains a heavy liquid, which allows urine to pass through while forming a seal against odors. Waterless urinals use zero water, discharge into standard, existing plumbing lines, and are easy to clean. Also, since urine is sterile and bacteria develop only when urine is mixed with water, waterless urinals remain odorless. Waterless urinals are currently used in San Diego schools, the L.A. Coliseum, and the Taj Mahal, and they have been mandated in army facilities since 2010. They also count towards LEED certification points. There really are no drawbacks to the waterless urinal save one – but it’s a big one: half the world’s population is women. Enough said.

Waterless urinals have gained in popularity and are becoming more widely used in commercial settings, even being approved by the plumbing code since 2006. They use gravity to force urine down through a trap that contains a heavy liquid, which allows urine to pass through while forming a seal against odors. Waterless urinals use zero water, discharge into standard, existing plumbing lines, and are easy to clean. Also, since urine is sterile and bacteria develop only when urine is mixed with water, waterless urinals remain odorless. Waterless urinals are currently used in San Diego schools, the L.A. Coliseum, and the Taj Mahal, and they have been mandated in army facilities since 2010. They also count towards LEED certification points. There really are no drawbacks to the waterless urinal save one – but it’s a big one: half the world’s population is women. Enough said.

Composting Toilets

A composting (or biological) toilet system contains and processes excrement, toilet paper, carbon additive, and sometimes, food waste. Unlike a septic system, a composting toilet system relies on unsaturated conditions where aerobic bacteria break down waste. This process is similar to a yard waste composter. If sized and maintained properly, a composting toilet breaks down waste to just 10-30% of its original volume. The resulting soil-like material, called “humus” legally must be either buried or removed by a licensed septage hauler in accordance with state and local regulations.

A composting (or biological) toilet system contains and processes excrement, toilet paper, carbon additive, and sometimes, food waste. Unlike a septic system, a composting toilet system relies on unsaturated conditions where aerobic bacteria break down waste. This process is similar to a yard waste composter. If sized and maintained properly, a composting toilet breaks down waste to just 10-30% of its original volume. The resulting soil-like material, called “humus” legally must be either buried or removed by a licensed septage hauler in accordance with state and local regulations.

Composting toilet systems require no water and have low power consumption. They can also accept kitchen waste, thus reducing household garbage. Composting toilets are the most environmentally friendly of the new generation of toilets. Composting human waste and burying it around tree roots and nonedible plants keeps organic wastes productively cycling in the environment, and composting toilet systems divert nutrient and pathogen-containing effluent from soil, surface water, and groundwater. In many states, installing a composting toilet system allows the property owner to keep a reduced-size leach field, minimizing costs and disruption of landscapes.

Of course, there are a few drawbacks as well. Maintenance of composting toilet systems requires more responsibility and commitment by users and owners than conventional wastewater systems, and improperly installed or maintained systems have the potential to cause some problems. Using an inadequately treated end-product as a soil amendment may have possible health consequences, and improper maintenance makes cleaning difficult and may lead to health hazards and odor problems. Too much liquid residual (leachate) in the composter can disrupt the process if it is not drained and properly managed. In addition, there may be aesthetic issues because the excrement in some systems may be in sight.

Incinerating Toilets

Incinerating toilets are self-contained units consisting of a traditional commode-type seat connected to a holding tank and a gas-fired or electric heating system to incinerate waste products deposited in the holding tank. The incineration products are primarily water and a fine, non-hazardous ash that can be disposed of easily and without infection hazard. Typically the user drops in a coffee-filter type liner, uses the toilet, then “flushesâ€. The liner drops into a chamber, which heats up to approximately 1200 degrees, and incinerates the waste over a period of time, usually one to two hours. As a safety feature, the incinerator automatically turns itself off if the lid is lifted, thus eliminating the chance of bathroom burns.

Incinerating toilets are self-contained units consisting of a traditional commode-type seat connected to a holding tank and a gas-fired or electric heating system to incinerate waste products deposited in the holding tank. The incineration products are primarily water and a fine, non-hazardous ash that can be disposed of easily and without infection hazard. Typically the user drops in a coffee-filter type liner, uses the toilet, then “flushesâ€. The liner drops into a chamber, which heats up to approximately 1200 degrees, and incinerates the waste over a period of time, usually one to two hours. As a safety feature, the incinerator automatically turns itself off if the lid is lifted, thus eliminating the chance of bathroom burns.

Incinerating toilets use no water at all, and they produce only about a tablespoon per use of a fine, sterile ash that can be disposed of in the trash. They are simple to install, easy to use, and are relatively odorless in comparison to other waterless toilets. However, they do also have some drawbacks. Incinerating destroys nutrients in the waste and also requires energy, resulting in higher than average energy costs for users. In addition, units are not entirely pollution-free, as they require either electricity or propane, both of which produce some air pollutants.

Hope for the Future

If we could save the third of our nation’s drinking water that we are flushing down our toilets, we would actually solve the nation’s water crisis. And researchers and engineers are working every day to do just that: to find a sustainable, cost-effective solution to the wastewater problem facing America. At the moment, there is not yet a universal answer to our nation’s toilet troubles. However, with the abundance of emerging technologies and the combined focus of researchers and engineers, it is only a matter of time before our wastewater – and therefore water – woes are permanently solved.

REFERENCES:

www.epa.gov

www.goarticles.com/finhuge

www.bestratedtoilets.com

Tata & Howard and Turner Engineering Announce Strategic Partnership

Tata & Howard and Turner Engineering Announce Strategic Partnership

Flagstaff engineering firms Tata & Howard and Turner Engineering have formed a partnership to provide comprehensive civil, water, wastewater, stormwater, and hazardous waste engineering services at one location.

FLAGSTAFF, AZ, May 8, 2014 – Tata & Howard, Inc., a leading innovator in water, wastewater, stormwater, and hazardous waste engineering solutions, and Turner Engineering, Inc., a professional civil engineering firm with extensive experience in Northern Arizona, announced today that they have formed a comprehensive partnership in order to provide the highest quality service to their Arizona clients.

Founded in 1992 in Marlborough, Massachusetts, Tata & Howard specializes in environmental engineering with targeted expertise in water, wastewater, stormwater, and hazardous waste services. Founded in 1986 in Flagstaff, Arizona, Turner Engineering brings over 28 years of successful experience in all aspects of civil engineering, including design, management, and permitting.

Tata & Howard, Inc., and Turner Engineering, Inc., both located at 528 West Aspen Avenue in Flagstaff, Arizona, are enthusiastic about the increased level of service and capability that they will bring to their clients.

“TEI brings extensive civil engineering experience to the table such as site planning and design, land subdivision infrastructure, planning, and design, and extensive understanding of all local and governmental permitting processes, while Tata & Howard brings their comprehensive environmental engineering services including water and wastewater master planning, treatment, and design, stormwater management and compliance, new source development and permitting, hazardous waste services including due diligence and site assessments, hydraulic modeling and GIS, and pipe condition assessment” remarked Paul W. Turner, P.E., President of Turner Engineering. “Both firms have extensive experience with energy efficiency studies and low impact design, which is a must for the environmentally conscious Flagstaff area.”

“With this alliance, we will integrate our firms’ combined knowledge and expertise to provide a unified service to our clients under one effort,” added Shira A. McWaters, P.E., Associate and Manager of Tata & Howard’s Flagstaff location. “Together we will provide our clients the attentive service of a small firm with the capabilities and experience of a large firm.”

About Tata & Howard, Inc.

Founded in 1992, Tata & Howard, Inc. is a specialized water, wastewater, stormwater, and hazardous waste consulting engineering firm with offices in Massachusetts, New Hampshire, Connecticut, Maine, Vermont, and Arizona. Tata & Howard utilizes a team approach with clients to provide a full range of innovative engineering services, from concept to completion, including reports, design, construction administration, resident observation, and start-up. In addition, Tata & Howard has worked with all sized markets, both public and private, to provide effective, inventive solutions. For more information, please visit tataandhoward.com.

About Turner Engineering, Inc.

Founded in 1986, Turner Engineering, Inc. is a professional civil engineering firm specializing in developing sites with unique and sensitive design challenges. TEI focuses on exceptional client service and provides a wide range of civil engineering services to private, commercial, institutional, and governmental clients including civil site design, drainage design, master planning, subdivision development, and roadway design, and has full working knowledge of permitting processes of local governmental agencies, FEMA, and Army Corps of Engineering (404) analysis and permitting. For more information, please visit www.teiaz.com.

Founded in 1986, Turner Engineering, Inc. is a professional civil engineering firm specializing in developing sites with unique and sensitive design challenges. TEI focuses on exceptional client service and provides a wide range of civil engineering services to private, commercial, institutional, and governmental clients including civil site design, drainage design, master planning, subdivision development, and roadway design, and has full working knowledge of permitting processes of local governmental agencies, FEMA, and Army Corps of Engineering (404) analysis and permitting. For more information, please visit www.teiaz.com.

Contact:

Karen Gracey, P.E.

Tata & Howard, Inc.

508-303-9400 x120

kgracey@tatandhoward.com

tataandhoward.com

James J. Courchaine joins Tata & Howard, Inc. as Vice President

James J. Courchaine joins Tata & Howard, Inc. as Vice President

Key hire brings over 40 years of innovative water and wastewater experience to its Flagstaff, Arizona office

FLAGSTAFF, AZ, March 31, 2014 – Tata & Howard, Inc., a leading innovator in water, wastewater, stormwater, and hazardous waste engineering solutions, has announced that James J. Courchaine has joined the firm as Vice President. Mr. Courchaine has over 40 years experience in every facet of water and wastewater management, operations, and maintenance. He assisted with the development of the first Capacity, Management, Operations, and Maintenance (CMOM) guidelines as well as authored the Wastewater Collection System Operator Certification Studybook. Mr. Courchaine developed an innovative assessment matrix and structural framework for utility operations evaluation and improvement and is recognized as a subject matter expert at the national level. In addition, he developed and taught water and wastewater management, operations, and maintenance courses at the college level. He is also honoree and first recipient of the James J. Courchaine Collection Systems Award. Mr. Courchaine will be working out of Tata & Howard’s Flagstaff, Arizona office located at 528 W. Aspen Avenue. He can be reached at 928-774-9500 or jcourchaine@tataandhoward.com.

FLAGSTAFF, AZ, March 31, 2014 – Tata & Howard, Inc., a leading innovator in water, wastewater, stormwater, and hazardous waste engineering solutions, has announced that James J. Courchaine has joined the firm as Vice President. Mr. Courchaine has over 40 years experience in every facet of water and wastewater management, operations, and maintenance. He assisted with the development of the first Capacity, Management, Operations, and Maintenance (CMOM) guidelines as well as authored the Wastewater Collection System Operator Certification Studybook. Mr. Courchaine developed an innovative assessment matrix and structural framework for utility operations evaluation and improvement and is recognized as a subject matter expert at the national level. In addition, he developed and taught water and wastewater management, operations, and maintenance courses at the college level. He is also honoree and first recipient of the James J. Courchaine Collection Systems Award. Mr. Courchaine will be working out of Tata & Howard’s Flagstaff, Arizona office located at 528 W. Aspen Avenue. He can be reached at 928-774-9500 or jcourchaine@tataandhoward.com.

About Tata & Howard, Inc.

Founded in 1992, Tata & Howard, Inc. is a specialized water, wastewater, stormwater, and hazardous waste consulting engineering firm with offices in Massachusetts, New Hampshire, Connecticut, Maine, Vermont, and Arizona. Tata & Howard utilizes a team approach with clients to provide a full range of innovative engineering services, from concept to completion, including reports, design, construction administration, resident observation, and start-up. In addition, Tata & Howard has worked with all sized markets, both public and private, to provide effective, inventive solutions. For more information, please visit tataandhoward.com.

Contact:

Karen Gracey, P.E.

Tata & Howard, Inc.

508-303-9400 x120

kgracey@tatandhoward.com

tataandhoward.com

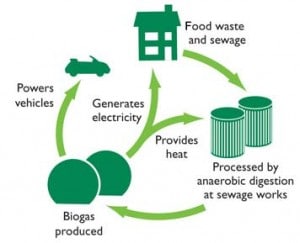

Powering Vehicles from Discarded Food: East Coast Meets West Coast

Last month, Massachusetts Governor Deval Patrick signed into law the Commercial Food Waste Ban, which will go into effect on October 1, 2014. This law targets commercial institutions who produce more than one ton of organic waste per week, such as hospitals, restaurants, schools, hotels, and supermarkets. Once the ban takes effect, this waste food, which accounts for 25% of the waste stream in the Commonwealth, will need to be recycled rather than discarded. Recycling food waste has many advantages. First, it brings awareness to businesses to simply be more mindful in food ordering, preparation, and potential donation in order to decrease the overall amount of food waste they produce. Next, it decreases food waste in landfills, and thus mitigates the amount of greenhouse gas entering the atmosphere from decomposition. Finally, it provides a clean energy source. And that is something this country desperately needs.

Last month, Massachusetts Governor Deval Patrick signed into law the Commercial Food Waste Ban, which will go into effect on October 1, 2014. This law targets commercial institutions who produce more than one ton of organic waste per week, such as hospitals, restaurants, schools, hotels, and supermarkets. Once the ban takes effect, this waste food, which accounts for 25% of the waste stream in the Commonwealth, will need to be recycled rather than discarded. Recycling food waste has many advantages. First, it brings awareness to businesses to simply be more mindful in food ordering, preparation, and potential donation in order to decrease the overall amount of food waste they produce. Next, it decreases food waste in landfills, and thus mitigates the amount of greenhouse gas entering the atmosphere from decomposition. Finally, it provides a clean energy source. And that is something this country desperately needs.

Anaerobic digestion (AD) is one way to dispose of organic waste that has the added benefit of producing clean energy. AD uses microbes to break down organic waste in an oxygen-deprived chamber, producing biogas, a clean and potent energy. Biogas is produced not just from food waste, but from any organic waste matter, including human waste, and is a clean energy option for heating and cooling, electricity, and powering vehicles. Wastewater treatment facilities that currently incorporate AD in their treatment processes could potentially be modified to handle food waste as well, and the Commonwealth is offering up $1M in grant funding for public facilities to do just that. In fact, the first grant of $100,000 has already been awarded to Massachusetts Water Resources Agency (MWRA) to process food waste at its wastewater treatment plant on Deer Island.

Connecticut and Vermont have passed similar laws, but they are using a more gradual approach. Both states currently only require businesses that are located within 20 miles of a suitable recycling facility and produce more than two tons of food waste per week to recycle, but expect full compliance by 2020. New York City is also implementing a food waste ban as a result of the success of its recently completed Food Waste Challenge, a six-month trial in which businesses voluntarily participated by donating unused food as well as diverting their scraps to a local treatment plant. The City noted that a key part of the initiative was food donation, as more than 25% of food waste diversion was a result of donations to local food banks. And businesses are supportive. Melissa Autilio Fleischut, president and CEO of the New York State Restaurant Association, commended the program and supported the litigation. “The Food Waste Challenge proves that sending less to landfills is good for both business and the planet,” Fleischut said in a press release. “The New York State Restaurant Association looks forward to working with the city to advance this initiative in a responsible way that works for everyone.”

On the other side of the country, waste-powered cars are swiftly becoming a reality. Hyundai, who has been working with the University of California, plans to begin leasing a fuel-cell version of its Tucson crossover that can travel about 480 kilometers on a tank of hydrogen, which is produced from AD and has zero emissions. The eco-friendly Tucson, which will only be available to California residents, has low lease rates which include free fuel from nearly a dozen hydrogen pumps around the state. Toyota, Honda, Mercedes-Benz and GM are starting to sell hydrogen cars in California as well.

California has long been a pioneer in green technologies. However, Massachusetts is the first state in the nation to actually implement a comprehensive ban on organic waste. While utilizing waste for energy has largely been voluntary and thus slow-moving, this legal mandate will force large-scale organic waste processing facilities into production, either through retrofitting of existing facilities or new construction. And these new processing centers will produce large amounts of biogas. So will the east coast finally start seeing the alternative fuel filling stations and vehicles that are currently reserved only for the west coast? Let’s hope so. If we could combine east coast legal mandates with west coast alternative fuel technology, the nation could see zero emissions vehicles running on discarded organic scraps and sewerage. Keep excess garbage from our landfills while powering pollutant-free vehicles? Now that’s a win-win.

Saxtons River, VT Considers UV Light Treatment for Wastewater

Saxtons River, Vermont is considering an upgrade to their aging wastewater treatment facility. Engineering firm Marquise & Morano introduced three plans to Saxtons River Trustees at a meeting, and Gary A. Leach, P.E., Vice President of Tata & Howard, presented an option using sequencing batch reactors (SBR) as the best option. The SBR process uses ultraviolet (UV) light instead of chlorine to treat wastewater. Not only is the SBR option the most economical, but it is also a green initiative. UV utilizes only light, and therefore eliminates all processes associated with the handling and transport of chemicals, and it is safer for operators and aquatic life. For more information on the Saxtons River wastewater treatment project, click here.