The Holiday season means many different things for people. Whether it’s getting everyone the perfect gift, spending time with family, or preparing favorite foods for friends, the holidays are a time of giving. Our family here at Tata & Howard takes holiday giving to heart. We understand how important philanthropy is to both our local and global community. For this special time of year, we are looking at some of the most charitable and full-hearted organizations we’ve had the honor to support.

DARE Family Services

Since 1964, DARE Family Services has been committed to improving the lives of children who have been abused or neglected. By providing a family-based setting, they give children the opportunity to recover and live healthy, happy lives. Every holiday season, DARE Family Services reaches out to communities for gift donations to help kids experience a memorable holiday – in many cases, for the first time in their lives. At Tata & Howard, our employee-owners take DARE’s mission to heart and bring gifts to put under our DARE Giving Tree for children in need. Fortunately, we are one of many organizations and individuals who support DARE and their determination to better the lives of disadvantaged and neglected children. They help thousands of kids every year and we thank them for their generosity.

Dana-Farber Cancer Institute

The Dana-Farber Cancer Institute, along with the Jimmy Fund, is home to groundbreaking cancer discoveries. They are one of the greatest examples of a philanthropic organization working for a worthy cause – curing cancer. There are seemingly endless ways Dana-Farber and the Jimmy Fund raise money and resources to give hope to families affected by cancer, especially during the holidays. Tata & Howard is a proud supporter of Dana-Farber and donated $5,300 towards cancer research this past November, and donated another $1,500 this week in lieu of sending printed holiday cards to clients and friends. Some of our employee-owners are doing their own part to help them out as well. Our Marketing Communications Manager Heidi White participated in their “Run Any Race” program and raised over $3,000 by running Ragnar’s Reach the Beach in New Hampshire this past September. Also, T&H Engineer Molly Coughlin is currently training for the 2017 Boston Marathon to raise money for Dana-Farber and the Jimmy Fund. Her personal goal is to raise $15,850 and we are all cheering her on. Go Molly!

Water For People

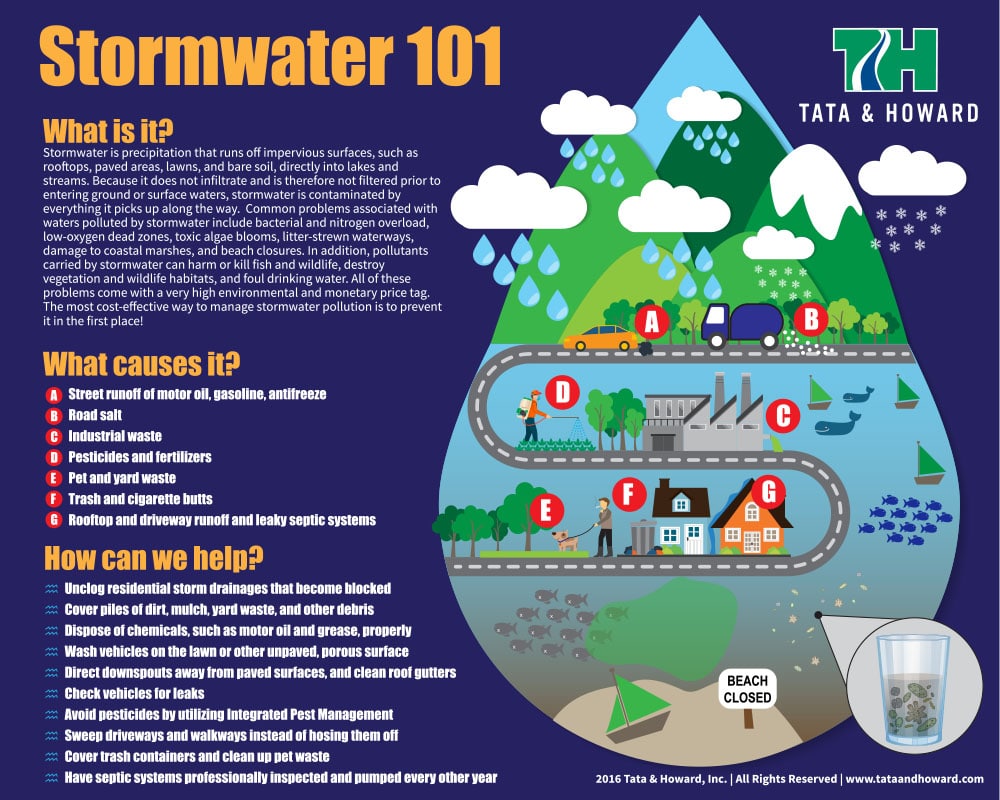

Over 1.8 billion people globally lack access to safe drinking water, and Water For People is looking to change that by committing to provide long-lasting water and sanitation infrastructure for communities in need. They operate in nine countries and have helped over four million people live better lives by providing access to clean water. To make this happen, Water For People works with communities, governments, and business owners to ensure reliable, safe water for future generations. In support of their passion for clean water, many employee-owners at Tata & Howard contribute to Water For People through automatic bi-weekly payroll deductions, which Tata & Howard matches dollar for dollar. In this way, we are able to do our part to realize Water For People’s mission of clean water for everyone, forever.

The Navajo Water Project

Speaking of clean water for everyone, the Navajo Water Project is an amazing organization that seeks to solve a little-known water problem. Of the nearly 200,000 Navajo population right here in America, 40% do not have running water – which has created a cycle of poverty that limits health, education, and economic security. As a subsidiary of DIGDEEP and primarily funded through private donors, the Navajo Water Project works with communities in Navajo Nation to install systems that bring running water and electricity into homes. The water is delivered via truck and safely stored in large cisterns, from which it is pumped into a sink and shower inside the home. The organization also installs solar energy systems to power the pumps and lights inside. With their determination and adequate funding, The Navajo Water Project expects to install home water systems in every Navajo home in need by 2018. Since we learned of the plight of the Navajo people in 2015, Tata & Howard has actively supported the Navajo Water Project. In 2017, which is our 25th anniversary year, we are organizing a national virtual 5K to raise money for this incredible organization. Participants will receive a beautiful medal and 100% of the cost of registration will go directly to the Navajo Water Project. Stay tuned for details of this exciting event!

The holiday season is the perfect time to give to others and to help the community, both locally and globally. Even the smallest gesture of generosity helps others in significant ways. And the best gift a person can receive is hope — and that is exactly what DARE Family Services, the Dana-Farber Cancer Institute, the Navajo Water Project, and Water for People are all about. We here at Tata & Howard encourage everyone to give to someone in need and celebrate generosity this holiday season. Happy Holidays to you and yours!

It is widely known that America’s infrastructure is in desperate need of repair, rehabilitation, and replacement, and that the

It is widely known that America’s infrastructure is in desperate need of repair, rehabilitation, and replacement, and that the

Clean Air Day is an opportunity to acknowledge how important air quality is to our health. Since 1963, December 17 has been a day to celebrate one of the first environmental laws in the United States – The Clean Air Act. Through collaboration, the EPA works with both state and local governments to ensure clean air for everyone. Among the biggest threats facing this campaign are volatile organic compounds (VOCs). Common in thousands of household products, VOCs are invisible to the naked eye and can have serious effects on human health.

Clean Air Day is an opportunity to acknowledge how important air quality is to our health. Since 1963, December 17 has been a day to celebrate one of the first environmental laws in the United States – The Clean Air Act. Through collaboration, the EPA works with both state and local governments to ensure clean air for everyone. Among the biggest threats facing this campaign are volatile organic compounds (VOCs). Common in thousands of household products, VOCs are invisible to the naked eye and can have serious effects on human health. The EPA provides many steps on how to avoid VOCs both indoors and outdoors. Simple and effective steps such as proper ventilation and reduced use of pesticides can greatly improve the quality of air inside your home or building. For potentially hazardous products such as varnishes or fuel, it is important to read all warning labels and practice safe storage and handling. The EPA also advises to keep minimum exposure to chemicals such as benzene and perchloroethylene, or “perc,” a chemical commonly used for dry cleaning. Currently, there is no federally enforceable standard set for VOCs in non-industrial settings such as a home or small business. To learn more about VOCs, including current guidelines or recommendations set by various organizations, visit

The EPA provides many steps on how to avoid VOCs both indoors and outdoors. Simple and effective steps such as proper ventilation and reduced use of pesticides can greatly improve the quality of air inside your home or building. For potentially hazardous products such as varnishes or fuel, it is important to read all warning labels and practice safe storage and handling. The EPA also advises to keep minimum exposure to chemicals such as benzene and perchloroethylene, or “perc,” a chemical commonly used for dry cleaning. Currently, there is no federally enforceable standard set for VOCs in non-industrial settings such as a home or small business. To learn more about VOCs, including current guidelines or recommendations set by various organizations, visit  To preserve and improve the health of all humans and other life on Earth, we must defend the planet’s air quality. The Clean Air Act has provided the basis for an effective means of limiting dangerous air pollutants for the last half century. This Act and its enforcement by the EPA has undoubtedly saved the lives of hundreds of thousands of people and continues to set new standards for air quality management. Many western European nations have enacted similar legislation, which is a big step in the right direction for clean air!

To preserve and improve the health of all humans and other life on Earth, we must defend the planet’s air quality. The Clean Air Act has provided the basis for an effective means of limiting dangerous air pollutants for the last half century. This Act and its enforcement by the EPA has undoubtedly saved the lives of hundreds of thousands of people and continues to set new standards for air quality management. Many western European nations have enacted similar legislation, which is a big step in the right direction for clean air! Water systems today face a set of problems that are unique to this generation. While our nation’s buried infrastructure is crumbling beneath our feet as it reaches the end of its useful life, supplies are dwindling, budgets are shrinking, and federal and state funding is drying up. At the same time, regulatory requirements continue to increase as emerging contaminants are identified. Water systems often find themselves in the quandary of whether to upgrade treatment systems to comply with these new regulations or update assets that are long overdue for replacement or rehabilitation.

Water systems today face a set of problems that are unique to this generation. While our nation’s buried infrastructure is crumbling beneath our feet as it reaches the end of its useful life, supplies are dwindling, budgets are shrinking, and federal and state funding is drying up. At the same time, regulatory requirements continue to increase as emerging contaminants are identified. Water systems often find themselves in the quandary of whether to upgrade treatment systems to comply with these new regulations or update assets that are long overdue for replacement or rehabilitation. In addition to addressing capital efficiency, water utilities of today must also address operational efficiency. Because water systems are required to do so much with so little, efficiency in all aspects of water system management is critical. Tata & Howard appreciates the unique set of challenges faced by water systems today, and we have experts on staff who understand the inner workings of a water utility – and how to improve them.

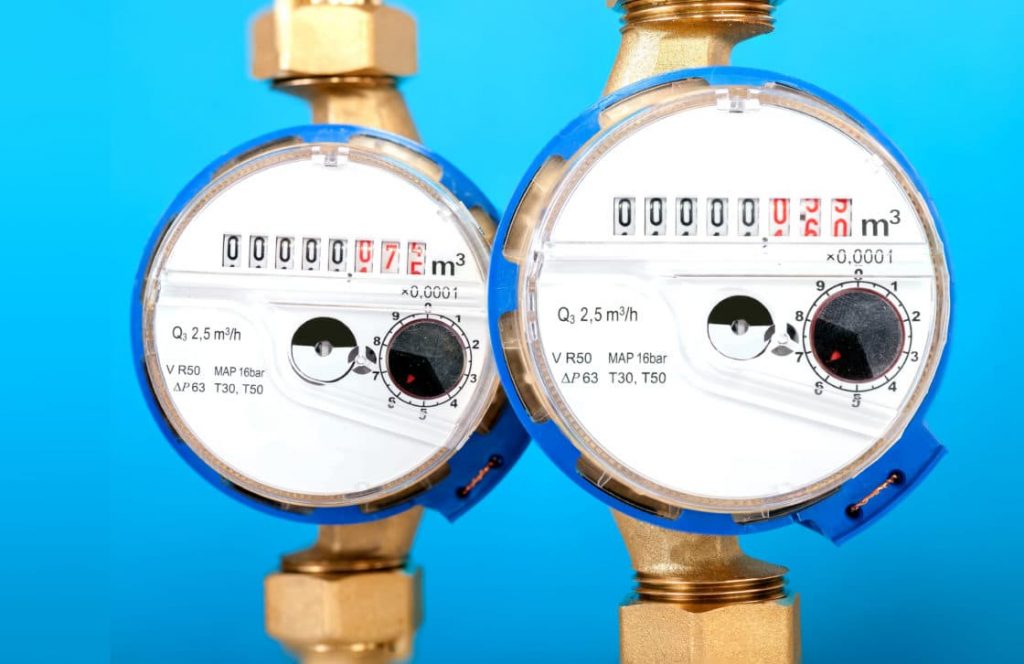

In addition to addressing capital efficiency, water utilities of today must also address operational efficiency. Because water systems are required to do so much with so little, efficiency in all aspects of water system management is critical. Tata & Howard appreciates the unique set of challenges faced by water systems today, and we have experts on staff who understand the inner workings of a water utility – and how to improve them. Besides improving operational and capital efficiency, water systems of today must reduce non-revenue water. Non-revenue water is treated drinking water that has been pumped but is lost before it ever reaches the customer, either through real losses such as leaks, or through apparent losses such as theft or metering issues. In the United States, water utilities lose about 20% of their supply to non-revenue water. Non-revenue water not only affects the financial health of water systems, but also contributes to our nation’s decreasing water supply. In fact, the amount of water “lost” over the course of a year is enough to supply the entire State of California for that same year. Therefore, the AWWA recommends that every water system conduct an annual water audit using M36: Water Audits and Loss Control methodology to accurately account for real and apparent losses.

Besides improving operational and capital efficiency, water systems of today must reduce non-revenue water. Non-revenue water is treated drinking water that has been pumped but is lost before it ever reaches the customer, either through real losses such as leaks, or through apparent losses such as theft or metering issues. In the United States, water utilities lose about 20% of their supply to non-revenue water. Non-revenue water not only affects the financial health of water systems, but also contributes to our nation’s decreasing water supply. In fact, the amount of water “lost” over the course of a year is enough to supply the entire State of California for that same year. Therefore, the AWWA recommends that every water system conduct an annual water audit using M36: Water Audits and Loss Control methodology to accurately account for real and apparent losses. It is widely known how important water is to our lives and the world we live in. Our body and planet is comprised of about 70% water – making it seem like it is easily accessible and plentiful. However, when you rule out our oceans and ice caps, less than 1% of all the water on Earth is drinkable. Of that less than 1%, groundwater only accounts for 0.28% of fresh water around the globe. Safe drinking water is a privilege we often take for granted while we brush our teeth or drink a glass of water in the morning. While we are giving thanks to our family, friends, and food during Thanksgiving, we should also give big thanks for our clean drinking water and the people who make it happen.

It is widely known how important water is to our lives and the world we live in. Our body and planet is comprised of about 70% water – making it seem like it is easily accessible and plentiful. However, when you rule out our oceans and ice caps, less than 1% of all the water on Earth is drinkable. Of that less than 1%, groundwater only accounts for 0.28% of fresh water around the globe. Safe drinking water is a privilege we often take for granted while we brush our teeth or drink a glass of water in the morning. While we are giving thanks to our family, friends, and food during Thanksgiving, we should also give big thanks for our clean drinking water and the people who make it happen.

October 23-29 is National Lead Poisoning Prevention Week 2016. Established in 1999 by the U.S. Senate, National Lead Poisoning Prevention Week (NLPPW) occurs every year during the last week in October and is now supported by the U.S. Environmental Protection Agency (EPA), the Centers for Disease Control and Prevention (CDC), the U.S. Department of Health and Human Services (HHS), the U.S. Department of Housing and Urban Development (HUD), and the World Health Organization (WHO). This year’s NLPPW theme of “Lead-Free Kids for a Healthy Future” underscores the importance of protecting our future by educating the public about the dangers and sources of lead poisoning and what can be done to prevent it. While lead-based paint is arguably the most common and hazardous source of lead exposure for young children,

October 23-29 is National Lead Poisoning Prevention Week 2016. Established in 1999 by the U.S. Senate, National Lead Poisoning Prevention Week (NLPPW) occurs every year during the last week in October and is now supported by the U.S. Environmental Protection Agency (EPA), the Centers for Disease Control and Prevention (CDC), the U.S. Department of Health and Human Services (HHS), the U.S. Department of Housing and Urban Development (HUD), and the World Health Organization (WHO). This year’s NLPPW theme of “Lead-Free Kids for a Healthy Future” underscores the importance of protecting our future by educating the public about the dangers and sources of lead poisoning and what can be done to prevent it. While lead-based paint is arguably the most common and hazardous source of lead exposure for young children,

Lead in drinking water cannot be detected through taste or smell, and the only way to know for certain if your drinking water has elevated lead levels is to have your water professionally tested. Typically, lead pipes are found in homes that were built prior to 1986 and in older cities. Older homes with private wells are also at risk of having lead in drinking water. While

Lead in drinking water cannot be detected through taste or smell, and the only way to know for certain if your drinking water has elevated lead levels is to have your water professionally tested. Typically, lead pipes are found in homes that were built prior to 1986 and in older cities. Older homes with private wells are also at risk of having lead in drinking water. While