Please feel free to print and share, with attribution, our Low Impact Development for Eco-Conscious Stormwater Management infographic. To download a high resolution pdf, please click here.

Please feel free to print and share, with attribution, our Low Impact Development for Eco-Conscious Stormwater Management infographic. To download a high resolution pdf, please click here.

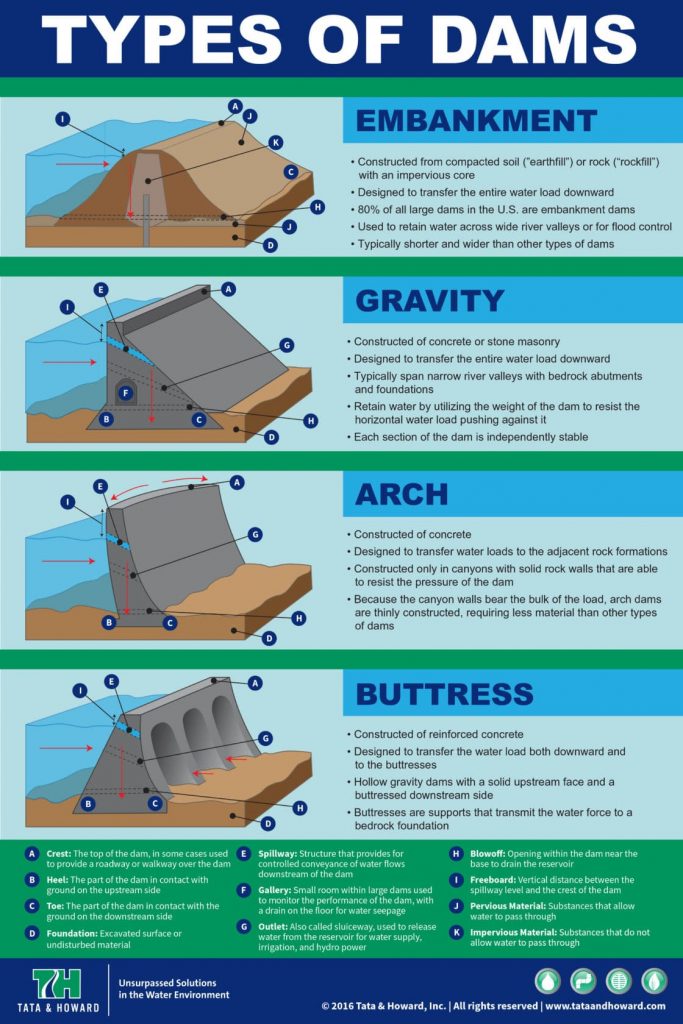

Please feel free to print and share, with attribution, our Types of Dams Infographic. A high resolution pdf can be downloaded by clicking here.

National Food Bank Week occurs annually during the week that contains October 16, which is World Food Day. World Food Day, first established in 1979, marks the formation of the Food and Agriculture Organization of the United Nations (FAO) on October 16, 1945. While World Food Day aims to bring global progress to food supplies and the impact of climate change, and has a lofty and noble goal of Zero Hunger by 2030, National Food Bank Week focuses more on the immediate need of those around us.

What is a Food Bank?

Food banks are non-profit organizations that collect multiple tons of food every year, which they then distribute to local food pantries and hunger relief charities. Food banks provide for collection and storage of food, but they do not typically distribute directly to those in need. Rather, they distribute to smaller agencies that have direct contact with those in need, but do not themselves have the means or the room for food collection.

Food banks collect food from a variety of sources. Grocery stores and wholesalers donate thousands of pounds of food that would otherwise be thrown away, and smaller organizations provide food and monetary donations through food drives, hunger walks, and other charitable measures. Food banks also accept food donated from individuals and families – the only caveat is that the food must not be expired.

Typically found in larger communities, food banks are almost fully reliant on volunteers and donors to help with day-to-day operations. Location has a huge impact on the functionality of each food bank, as more rural areas require smaller banks that distribute across larger distances, whereas large, urban areas require very large facilities to adequately support the serious need in those areas.

How Do Food Banks Work?

Food banks not only act as collection and distribution centers for food, they also serve as community leaders in assisting the diverse populations of those who are hungry. Food banks interact with elected officials and work towards legislation that supports hunger programs while also examining the contributing factors of poverty and hunger. Food banks then work to create and implement programs for clients, donors, and agencies that best respond to the local need.

There are myriad reasons why an individual is hungry. Job loss, medical crisis, low wages, and divorce are just a few of the reasons why a person or family may find themselves in need. And while the cause of hunger is of primary concern to food banks and how they best operate, answering the need should be the only concern of those of us fortunate enough to not be hungry.

How We Can Help

Food banks are always in need of donations and volunteers. During the holiday season, food banks receive more donations than they do during the rest of the year, which allows them to provide for the significant amount of holiday hunger. However, it is important to note that hunger happens year-round, and that food donations are always gladly accepted. Bringing a few bags of healthy, non-perishable food to the local food bank during the spring, summer, and fall months is an easy and affordable way to make a positive impact in the local community.

One of the best ways to make a big impact with minimal effort is to hold a food drive at the office. When a large group of people comes together to donate food, the amount collected adds up quickly. To collect even more food, consider creating groups within the organization and having a contest to see which group brings in the most pounds of food or fills the most boxes. A little friendly competition not only brings in a significantly larger amount of food, but also brings employees together, creating a positive atmosphere of teamwork and philanthropy.

In Conclusion

National Food Bank Week is an excellent time to reflect on the serious amount of hunger around us, and to come together to help provide for those in need. It is also a perfect time to get to know your local food bank, and to find out what types of donations they most need and how to most effectively help. Whether donating food, volunteering time, or providing financial support, food banks welcome any help they are given, particularly as we approach the holiday season. To find a local food bank, please visit www.feedingamerica.org/find-your-local-foodbank.

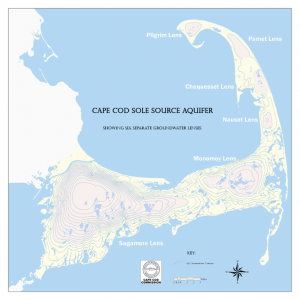

Cape Cod is an iconic New England vacation spot with beautiful beaches, sunny skies, magnificent marshes…and a serious water problem. Cape Cod has experienced contaminated drinking water throughout its history, and problems continue to this day. Pharmaceuticals, consumer product chemicals, and other emerging contaminants can be found in many of the public drinking water wells on Cape Cod. The Cape has 560 miles of coastline, 1,000 kettle-hole ponds, and one sole source aquifer containing two major and four smaller lenses, all in jeopardy.

Cape Cod is an iconic New England vacation spot with beautiful beaches, sunny skies, magnificent marshes…and a serious water problem. Cape Cod has experienced contaminated drinking water throughout its history, and problems continue to this day. Pharmaceuticals, consumer product chemicals, and other emerging contaminants can be found in many of the public drinking water wells on Cape Cod. The Cape has 560 miles of coastline, 1,000 kettle-hole ponds, and one sole source aquifer containing two major and four smaller lenses, all in jeopardy.

Other than Long Pond in Falmouth, all the drinking water on the Cape comes from the underground aquifer. Cape Cod has immensely permeable soil consisting of sand and gravel that make the Cape Cod Aquifer extremely susceptible to contamination. Unlike other parts of Massachusetts where groundwater may take a decade to travel a foot underground, groundwater on the Cape can travel a foot a day. In many parts of the Cape, the water table only sits ten feet or less below the surface, which means that whatever water lands on the ground could potentially contaminate water very quickly.

Septic Issues on the Cape

The most widespread problem facing Cape Cod’s water quality is septic discharge. Eighty-five percent of residents on the Cape use home septic systems to treat wastewater, and everything flushed down the toilet in these systems flows into a septic tank that is typically buried in the backyard. In the tank, solids settle to the bottom, while the liquids discharge into a leach field near the tank. This liquid then trickles down into the ground where, hopefully, it is diluted, filtered, and digested by microorganisms in the soil. It is important to note that these systems do not remove the emerging contaminants. While these systems typically function properly in rural areas, they tend to falter in more populous areas with high groundwater table. With Cape Cod’s population skyrocketing during summer months, coupled with highly permeable soil and a high water table, water contamination can be a huge issue.

The Environmental Side of the Problem

Besides the obvious human health risks associated with contaminated water from septic systems, the implications of contamination have taken a toll on Cape Cod’s economy and environment. The excess nitrogen and phosphorous in septic discharge, along with stormwater runoff, have created toxic algae blooms in many lakes and along the coastline. These blooms not only smell and look awful, they have caused mass die-offs of fish and are a threat to human health. The Cape has closed off swimming ponds but has not yet seen blooms as severe as Florida’s summertime blue-green algae crisis. Cape Cod’s seasonal economy could be crippled if algae blooms reached the level of those seen in Florida.

Finding a Solution

For over a decade, Cape Cod towns have struggled to solve water contamination problems and restore the health of their estuaries. Many towns developed plans to provide wastewater infrastructure to homes and businesses to restore water quality. Unfortunately, few of these plans have actually been implemented due to their capital costs ranging from $100-$700 million each. The total needed capital investment is over $2 billion for infrastructure better suited for the fluctuating Cape Cod population.

In support of a significant Cape Cod water quality initiative, Governor Charlie Baker certified a plan, developed by the Cape Cod Commission — the regional land use planning, economic development, and regulatory agency created in 1990 to serve the citizens and 15 towns of Barnstable County — and approved by the EPA, called the 208 Plan. The 208 Plan is a watershed-based approach to restore embayment water quality on Cape Cod. The plan recommends strategies, regulatory reforms, and a process for communities to reduce or eliminate excess nitrogen, the primary concern with septic discharge. The plan considers remediation and restoration approaches, in addition to source reduction. The plan also identifies areas with suitable development density for collection systems and wastewater treatment plants and identifies areas best suited for lower cost watershed and embayment technologies.

Another important initiative for Cape Cod’s water supply is the Cape Cod Regional Wastewater Management Plan. The Cape Cod Commission received nearly $3.5 million from the state to implement a wastewater plan that addresses Cape Cod’s water quality issues, and restoring those waters to levels where they are able to meet state water quality standards. The plan represents a framework and set of tools for identifying several solutions for each watershed of the Cape. The goal is to advance decision making toward cleaner water through implementation of sustainable and affordable approaches. The plan is a living document which will be updated frequently to reflect new knowledge, information, decisions, and community input.

To help address stormwater pollution, MassDEP issued the revised General Permit for Small Municipal Separate Storm Sewer Systems (MS4s) this past April, which goes into effect on July 1, 2017. In addition to the six Minimum Control Measures included in the original 2003 Permit, the 2016 Massachusetts MS4 General Permit also specifically includes limits to Total Maximum Daily Loads (TMDLs). TMDLs set pollution limits that represent the maximum amount of pollutant a specific body of water can handle before marine life, wildlife, and/or recreational uses become adversely affected.

An important stormwater initiative to improve the Cape’s water quality is Project STORM (Stormwater Outreach for Regional Municipalities). Coordinated by the Cape Cod Commission water resources staff, Project STORM is a collaborative effort of Cape Cod towns to pool resources and solutions to mitigate the impacts of stormwater and to educate the general public on effective means to reduce stormwater pollution, including structural and non-structural Best Management Practices (BMPs) as well as Low Impact Development (LID) concepts. The project also provides assistance to towns that must comply with EPA National Pollutant Discharge Elimination System (NPDES) Phase II stormwater regulations.

An important stormwater initiative to improve the Cape’s water quality is Project STORM (Stormwater Outreach for Regional Municipalities). Coordinated by the Cape Cod Commission water resources staff, Project STORM is a collaborative effort of Cape Cod towns to pool resources and solutions to mitigate the impacts of stormwater and to educate the general public on effective means to reduce stormwater pollution, including structural and non-structural Best Management Practices (BMPs) as well as Low Impact Development (LID) concepts. The project also provides assistance to towns that must comply with EPA National Pollutant Discharge Elimination System (NPDES) Phase II stormwater regulations.

In Conclusion

Cape Cod is faced with a very unique and challenging water problem. While there is no go-to solution to Cape Cod’s water troubles, communities and government are finally working together to fund and plan wastewater improvements. Through collaboration and studies, Cape Cod communities can now put plans in place for collection systems, additional wastewater treatment facilities, and all around best practices for preserving their local waterways. Protecting Cape Cod’s groundwater is critical to the environmental and economic health of the Cape. It is also a crucial step to ensure that future generations are able to enjoy the same endless coastlines, beautiful skies, sandy beaches, and memorable vacations that have made Cape Cod a beloved summer destination since the 19th century.

In recent years, there has been a lot of controversy surrounding Columbus, particularly for his treatment of the native peoples he found in the new land. In fact, many Americans support either changing the Columbus Day holiday to Indigenous People’s Day as the City of Berkeley, California did in 1992, or of abolishing the holiday altogether. Rather than discuss the value, or lack thereof, of Columbus and his voyages, we are examining six interesting facts about Columbus — from an environmental engineer’s point of view:

Finally finding a country to fund his dubious plan, Christopher Columbus and about 120 crew members set sail from Palos, Spain on August 3, 1492. His expedition sailed in search of a direct water route to China, India, and Asia — and the valuable spices they held. They spotted land on October 11, 1492, and on October 12, 1492, Columbus and his crew landed on what is likely Watling Island in the Bahamas. Columbus thought he had landed on India, and named the land the Indies. Later that same year, Columbus sighted Cuba, which he mistook for China, and Hispaniola, which Columbus mistook for Japan. In actuality, Columbus and his crew were over 8,000 miles away from their intended target, offering further proof that his calculation skills were less than exemplary. In fact, Columbus died maintaining that he had found a new passage to India. To stubbornly justify his position, he proposed that the Earth was pear-shaped, making him the laughing stock of Europe.

During the 43-day long voyage, chamber pots were used and emptied overboard, people wore the same set of clothes they set sail in, and fleas and rats ran rampant. Needless to say, sanitation was a huge issue, and every single person—including Columbus—had lice. People of the time didn’t understand the importance of hygiene in the prevention of disease. Today, things are much different. Even our wastewater is so highly treated that it is actually potable.

The United States is currently in the midst of hurricane season, which runs from June 1 – November 30. With the threat of hurricanes, such as Hurricane Matthew, come concerns over flooding, property damage, and power outages. In addition, falling trees and debris, broken but live electrical wires, and areas of flooding pose a major threat to human safety. However, there is another significant but often overlooked threat to human health that frequently occurs during hurricanes: water quality degradation.

Hurricanes typically bring with them massive amounts of precipitation – far more than the earth can handle. These surges create giant runoff situations, where pollution, contaminants, trash, and chemicals from the ground are pushed into the local water supply. To make matters worse, water treatment plants are often not able to handle the sudden, significant increase in contaminants, and also may not be working at full capacity due to power outages. This flooding also affects water mains and household lines, sometimes causing the water to bypass water treatment altogether.

But that’s not all. The pounding rain and storm surges brought by hurricanes can also overwhelm sewer systems, causing sewage overflows. The massive flooding of Hurricane Sandy in 2012 overwhelmed the region’s wastewater treatment plants, causing 11 billion gallons of largely untreated sewage to flow into waterways and city streets, mostly in New York City and New Jersey. In addition, the pounding surge caused significant damage to treatment plants, further complicating the issue, and contaminating water supplies.

Lastly, overwhelming amounts of rain and surge as seen with hurricanes can cause excessive amounts of dissolved organic matter (DOM) — soluble organic materials composed of the remains of organisms such as plants and animals and their waste products — to enter waterways. DOM causes a plethora of problems in drinking water: it easily binds with metal pollutants and carries them to reservoirs and lakes, it blocks pathogen-reducing ultraviolet rays, and it also enhances the formation of disinfection byproducts, which are carcinogenic.

Hurricanes clearly have the ability to not only damage personal property and threaten human safety, but also wreak havoc on our nation’s water supply. The combination of increased contamination, decreased treatment, overflowing sewer systems, and excessive DOM in the water has the potential to cause serious water quality issues. Therefore, during hurricane events, it is always smart to be prepared. Prior to the storm, stock up on bottled water. While municipal water should always be the drink of choice in normal day-to-day living since bottled water has its own set of problems, the safe choice when water quality issues arise as a result of a hurricane is bottled water. After the storm, check on the status of your area’s water quality. Until the authorities give your local municipal water the all clear, stick to bottled water for drinking.

For up-to-the-minute updates on Hurricane Matthew, please visit www.weather.com. And stay safe!

Water and energy are the two most fundamental ingredients of modern civilization. The water-energy nexus is the relationship between how much water is evaporated to generate and transmit energy, and how much energy it takes to collect, clean, move, store, and dispose of water. Without water, people die. Without energy, we cannot grow food, run computers, or power homes, schools, or offices. As the world’s population grows in number and affluence, the demands for both resources are increasing faster than ever.

The Water-Energy Connection

Energy production is the second largest consumer of water, the first being agriculture. Electric power plants that are fueled by oil, coal, natural gas, or nuclear power require exorbitant amounts of water to cool them, and hydropower plants require water to create energy. Likewise, a significant amount of energy is used in the pumping, treatment, and distribution of water, as well as in the collection, treatment, and disposal of wastewater. In addition, the extraction of fossil fuels used for heating and cooling homes also requires vast amounts of water. Clearly, the relationship between energy and water is inexorably intertwined.

As the population and affluence of the nation continues to increase, so does the demand for both water and energy. Also, climate change has been responsible for increasingly frequent water shortages, requiring communities to find water elsewhere – which requires even more energy. Pumping water from distant areas or glacial icecaps, desalinating ocean water, and highly treating wastewater to potable standards all require exorbitant amounts of energy. Previously, these methods for obtaining potable water were ignored due to their high energy usage. But as water shortages and drought continue to plague the nation, even affecting the historically wet northeast part of the country, more creative ways of meeting the nation’s demand for water must be innovated and implemented.

Likewise, fossil fuels such as oil and gas are being withdrawn at an unsustainable rate, and supplies are dwindling. As these inexpensive energy sources are depleted, our dependence on alternate, more water-intensive sources of energy increases. This endless cycle of water-energy usage has the potential to spiral out of control, and the only way to make a real and lasting change is for policy makers, businesses, and communities to join forces in the planning, management, and conservation of resources and in the innovation of sustainable solutions.

Planning and Management

One of the key factors to a sustainable future is communication. In the United States, there is little overlap in governmental agencies when it comes to water and energy. The Department of Energy has been an entity since 1977, and yet our nation still does not have an agency dedicated solely to water planning. While the EPA oversees water quality and the U.S. Geological Survey collects and interprets data related to supply, there is no single federal agency that ensures the effective use of water. In fact, much of the onus of water management lies not with the federal government, but with state agencies and municipalities. This can prove problematic when aquifers or watersheds span multiple cities and town, or even states. A logical approach to water management would be a federal agency that oversees all aspects of water management, from quality to supply to usage. In this way, federal energy and water agencies could collaborate to help forge a sustainable future. For example, when a new power plant is proposed, discussions should take place on not only the siting and permitting of the new facility, but also the effect on air and water quality, as well as water usage and potential for scarcity. In this way, more focused attention on the usage and effects of both energy and water will lead to more holistic — and sustainable — installations.

Value and Conservation

One of the greatest concerns of the modern day American is the risk of running out of inexpensive oil. The cost of oil pushed gasoline prices to $4.48 per gallon in 2008, and was partially responsible for the great recession of 2009. Realizing that the end of cheap oil could spell economic disaster, many people have begun to look at alternate heating sources for their homes, and alternate means to power their vehicles, such as biofuels or electricity. But how much more disastrous would it be to run out of cheap water? Peak oil would admittedly cause economic difficulty as well as some amount of human hardship, but peak water has the potential to cause far direr consequences. Millions of people globally already die from lack of access to an improved water source, and peak water would increase that number exponentially.

It is critical that the value of water be realized if we are to start making real changes. Gasoline prices are currently around $2.20 per gallon, while a gallon of municipal water costs less than one penny. And yet, we can live without gasoline – we cannot live without water. As society begins to understand that procuring, treating, and distributing water is an expensive task and that supplies are limited, we can innovate technologies that reduce the amount of freshwater that we use. For example, in the western part of the country, the Ogallala aquifer is being depleted at a rate far higher than it is being replenished, and irrigation accounts for 94% of the groundwater withdrawals in that area. Switching to a more water efficient irrigation process such as drip irrigation rather than spray would save a significant amount of water. Also, utilizing reclaimed water for crop irrigation, cooling power plants, and industry would greatly reduce our groundwater withdrawals. Even at the residential level, conservation is important. Community outreach programs and educational materials can be used to teach residents how they can save water in their homes and businesses. Simple, low-cost initiatives such as mowing grass to a higher level, utilizing rain barrels, and planting native trees and plants can have a huge impact when implemented on a large scale.

And let’s not forget about energy. Energy conservation is directly linked to water conservation, and it is critical that saving energy happen at both the industrial and residential levels. All businesses should examine their energy efficiency and implement energy-saving initiatives. And businesses that utilize a lot of water, such as hospitals and hotels, should conduct water audits to examine and modify their water usage. Wastewater treatment should include technologies that create energy from waste, such as anaerobic digestion, in order to offset the energy used in treatment processes. Likewise, homeowners should be educated on the importance of saving energy. Utilizing energy efficient lighting, turning the heat down by a degree or two, and unplugging appliances, computers, and chargers that are not in use are just a few of the ways that the individual American can save energy. In addition, heating residential water uses a significant amount of energy, while solar water heating is a simple technology that is as inexpensive as it is effective and efficient. Unfortunately, it has not received any type of federal backing or media attention, and remains relatively unknown. Both education and policy are critical to the widespread implementation of energy saving initiatives.

In Conclusion

Energy and water are both precious resources that are critical to our health, our economy, and our way of life — and they are inextricably linked. Of the utmost importance is that we value water. Until water has a realistic price on it, as energy does, it will be seen as a resource that can be used and wasted at free will. Only with accurate pricing can the link between water and energy be made apparent to consumers, and that conserving water conserves energy, and vice versa. Likewise, with true pricing consumers would see that as the price of water increases, so does the price of energy, and that as the price of energy increases, so does the price of water. Feeling the effects in our pockets would increase the appearance of value, act as a strong motivator to more aggressive conservation, and would prompt the innovation and implementation of more efficient, green solutions.

Imagine a day without water. Nearly every single thing we do is reliant on water. Right at the start of our day, we would not be able to use the bathroom, take a shower, brush our teeth, or make a cup of coffee. There would be no cleaning dishes, mopping floors, or cooking food. Water is something we use constantly throughout the day without even thinking about it, and has therefore become something we take for granted. For that reason, Imagine a Day Without Water was first introduced in 2015 in order to bring awareness to the value of water.

Imagine a day without water. Nearly every single thing we do is reliant on water. Right at the start of our day, we would not be able to use the bathroom, take a shower, brush our teeth, or make a cup of coffee. There would be no cleaning dishes, mopping floors, or cooking food. Water is something we use constantly throughout the day without even thinking about it, and has therefore become something we take for granted. For that reason, Imagine a Day Without Water was first introduced in 2015 in order to bring awareness to the value of water.

Think about how frustrating it is when our internet or cell phone service is interrupted. Having no signal or losing WiFi on our laptops can grind work to a halt, as well as bring about headaches and aggravation — but it doesn’t actually affect our health or our lives. And yet, in America we pay approximately $50 per month for internet, $75 per month for our cell phone bill, and a whopping $100 for the luxury of cable television. Ironically, the average monthly water bill is only about $30, and people often bemoan the fact that the cost of water has been increasing in recent years. The reality is that providing safe, clean drinking water and treating our wastewater is extremely complicated – and costly.

Think about the way water enters our homes and businesses, and of how our wastewater leaves it. There are literally thousands of pipes underground that we never see, and many of these pipes are approaching the end of their useful life. After all, most of our infrastructure was built around the time of World War II, and is now over 70 years old. In fact, much of the infrastructure in New England is well over 100 years old. These pipes and treatment plants are in desperate need of repair and replacement. In addition, our drinking water is treated to meet increasingly stringent regulations that protect our health. Bacteria, toxins, metals, and other harmful substances are all removed from the water prior to it entering the distribution system, and this treatment is expensive. In the same way, the wastewater that leaves our homes and businesses is highly treated and cleaned before it is returned to the environment, protecting public health from the myriad toxins and diseases found in untreated wastewater.

Think about the way water enters our homes and businesses, and of how our wastewater leaves it. There are literally thousands of pipes underground that we never see, and many of these pipes are approaching the end of their useful life. After all, most of our infrastructure was built around the time of World War II, and is now over 70 years old. In fact, much of the infrastructure in New England is well over 100 years old. These pipes and treatment plants are in desperate need of repair and replacement. In addition, our drinking water is treated to meet increasingly stringent regulations that protect our health. Bacteria, toxins, metals, and other harmful substances are all removed from the water prior to it entering the distribution system, and this treatment is expensive. In the same way, the wastewater that leaves our homes and businesses is highly treated and cleaned before it is returned to the environment, protecting public health from the myriad toxins and diseases found in untreated wastewater.

Failing pipes from our aging infrastructure also account for an astronomical amount of clean, treated drinking water that never reaches the consumer, and is never billed. This “lost” water comes at a staggering cost. To put it into perspective, the cost of this lost water is approximately $2.6 billion annually — which is approximately equivalent to the annual amount that the federal government allots to fund our water infrastructure — and the 1.7 trillion gallons of lost water is about the same amount of water needed to fully supply America’s ten largest cities.

Another challenge faced by utilities today is our growing national population combined with historic drought and climate change. This increased demand in the wake of a dwindling supply is placing extra pressure on our water and wastewater systems, and requires thoughtful, long-term solutions if we are going to be able to meet current and future demands. Add to that the recent focus on our nation’s lead service lines and the fact that they absolutely need to be replaced, and it becomes clear that our water and wastewater systems are in desperate need of attention — and investment.

Another challenge faced by utilities today is our growing national population combined with historic drought and climate change. This increased demand in the wake of a dwindling supply is placing extra pressure on our water and wastewater systems, and requires thoughtful, long-term solutions if we are going to be able to meet current and future demands. Add to that the recent focus on our nation’s lead service lines and the fact that they absolutely need to be replaced, and it becomes clear that our water and wastewater systems are in desperate need of attention — and investment.

Imagine a Day Without Water is a national movement that is looking to change the way we look at water, which is currently highly undervalued. It is by far the least expensive of all of our utilities, and yet it is the only one without which we cannot live. Consider that the cost to repair our nation’s water and wastewater infrastructure will require an estimated investment of $4.8 trillion over the next 20 years, and it becomes apparent that the time to invest is now. The key to funding our nation’s water and wastewater systems is education and placing the proper value on water. It is crucial that legislators and ratepayers support utilities in their efforts to upgrade and replace infrastructure, to address the funding gap for these critical projects, and to acknowledge and address the water supply challenges that we currently are facing.

We have reached the point where we must proactively address and invest in our nation’s water and wastewater infrastructure — before it is too late. Imagine a Day Without Water is a day in which we can all spread the word about the value of water by encouraging friends, family, and colleagues to imagine what their lives would be like without water. With proper planning and smart investment from both consumers and our legislators, living without water is something that will never come to fruition in our nation. Join the movement today by participating in Imagine a Day Without Water. For the many no-cost ways in which you can participate, including signing a petition, joining a Thunderclap, and becoming involved on social media, please visit https://imagineadaywithoutwater.org/participate.

We have reached the point where we must proactively address and invest in our nation’s water and wastewater infrastructure — before it is too late. Imagine a Day Without Water is a day in which we can all spread the word about the value of water by encouraging friends, family, and colleagues to imagine what their lives would be like without water. With proper planning and smart investment from both consumers and our legislators, living without water is something that will never come to fruition in our nation. Join the movement today by participating in Imagine a Day Without Water. For the many no-cost ways in which you can participate, including signing a petition, joining a Thunderclap, and becoming involved on social media, please visit https://imagineadaywithoutwater.org/participate.

By now, everyone has heard of the water crisis that occurred in Flint, Michigan when the City switched the source of its municipal water from the Detroit system to the Flint River in an effort to cut costs. Anti-corrosion chemicals were not added to the water, allowing lead to leach from the City’s aging pipes into the water supply. In the aftermath, hundreds of children suffered lead poisoning, officials were fired, arrests were made, and lawsuits were filed. And while the Flint disaster was arguably terrible and tragic, it has brought much-needed attention to the state of our nation’s infrastructure, and the criticality of maintaining and improving it.

Lead Service Lines in the United States

There are an estimated six million lead pipes remaining in use in the United States, utilized by over 11,000 water systems that serve nearly 22 million Americans, yet there is no federal plan in place to replace these lead service lines. Why? First, it would cost an exorbitant amount of money — roughly $30 billion — to replace every single remaining lead service line, money that utilities simply do not have. With failing infrastructure, dwindling budgets, more stringent regulatory requirements, and increased demand, utilities are doing everything they can simply to maintain service and compliance. To mitigate lead in drinking water, utilities that are unable to dig up all their lead service lines are instead treating water so that it forms a coating on the interior of the pipes. This coating serves as a protective barrier between the water and the lead pipes, preventing lead from leaching into the water supply. This methodology requires extreme vigilance, as water chemistry often changes, which can cause corrosion controls to fail. Fortunately, utilities regularly test their water for lead contamination, and on February 29, 2016, the EPA changed testing regulations to more accurately reflect the amount of lead in drinking water.

Lead in the Drinking Water of Public Schools

While utilities are working diligently to keep our nation’s water lead-free, public schools have recently come under fire, as schools from cities across the nation — including Boston, Massachusetts; Ithaca, New York; Portland, Oregon; and Tacoma, Washington — have found lead in their drinking water above the EPA’s action level of 15 parts per billion. Surprisingly, this contamination is the result of a legal loophole that many states are looking to close: schools are mandated by the EPA to be connected to a water supply that is regularly tested for lead and other contaminants; however, these utilities are not typically required to actually test the water inside the schools themselves. Considering that the average age of a school in the United States is 44 years old, it should come as no surprise that there are elevated levels of lead in the drinking water of public schools. After all, lead pipes were legal until about 30 years ago, and faucets and fixtures were allowed to contain up to 8% lead until 2014.

While utilities are working diligently to keep our nation’s water lead-free, public schools have recently come under fire, as schools from cities across the nation — including Boston, Massachusetts; Ithaca, New York; Portland, Oregon; and Tacoma, Washington — have found lead in their drinking water above the EPA’s action level of 15 parts per billion. Surprisingly, this contamination is the result of a legal loophole that many states are looking to close: schools are mandated by the EPA to be connected to a water supply that is regularly tested for lead and other contaminants; however, these utilities are not typically required to actually test the water inside the schools themselves. Considering that the average age of a school in the United States is 44 years old, it should come as no surprise that there are elevated levels of lead in the drinking water of public schools. After all, lead pipes were legal until about 30 years ago, and faucets and fixtures were allowed to contain up to 8% lead until 2014.

Lead poisoning is particularly detrimental to school-aged children, and public outcry — largely as a result of Flint’s crisis — has spurred many schools to voluntarily test their water. The findings have been shocking to parents and educators, as school across the nation, from Maine to Washington state, are reporting lead levels above the EPA’s action level. Every day, another news story crops up with a report on elevated lead in a county’s school system, and it becomes apparent that our nation has a serious problem on its hands. Just as with water utilities, the ideal solution would be to replace all the lead pipes and fixtures in our nation’s schools, but again, funding for large-scale replacement just isn’t available. Instead, many schools have turned to lead filters, which work extremely well when maintained regularly.

Looking Ahead

Many states have introduced legislation this year that would require public schools to regularly test their water. Bills on the table in Michigan, New Jersey, North Carolina, and Rhode Island would require regular testing, as would a New York bill that takes it one step further by providing funding for said testing. In addition, the New York bill would require schools to notify parents and to provide an alternate supply of safe drinking water to students if elevated lead levels are found. In Massachusetts, all community water systems are required by Massachusetts drinking water regulations to collect lead and copper samples from at least two schools or early education and care program facilities that they serve in each sampling period, when they collect their Lead and Copper Rule (LCR) samples. In addition, in April of 2016, it was announced that $2 million from the Massachusetts Clean Water Trust (MCWT) will fund cooperative efforts to help Massachusetts public schools test for lead and copper in drinking water. The funds, to be used by the Massachusetts Department of Environmental Protection (MassDEP), will provide technical assistance to ensure that public school districts can sample the taps and water fountains in their schools, and to identify any results that show lead and copper contamination over the action level. On a federal level, legislation has been introduced to Congress that would requires states to assist schools with testing for lead; however, it does not provide funding.

Many states have introduced legislation this year that would require public schools to regularly test their water. Bills on the table in Michigan, New Jersey, North Carolina, and Rhode Island would require regular testing, as would a New York bill that takes it one step further by providing funding for said testing. In addition, the New York bill would require schools to notify parents and to provide an alternate supply of safe drinking water to students if elevated lead levels are found. In Massachusetts, all community water systems are required by Massachusetts drinking water regulations to collect lead and copper samples from at least two schools or early education and care program facilities that they serve in each sampling period, when they collect their Lead and Copper Rule (LCR) samples. In addition, in April of 2016, it was announced that $2 million from the Massachusetts Clean Water Trust (MCWT) will fund cooperative efforts to help Massachusetts public schools test for lead and copper in drinking water. The funds, to be used by the Massachusetts Department of Environmental Protection (MassDEP), will provide technical assistance to ensure that public school districts can sample the taps and water fountains in their schools, and to identify any results that show lead and copper contamination over the action level. On a federal level, legislation has been introduced to Congress that would requires states to assist schools with testing for lead; however, it does not provide funding.

In Conclusion

As long as lead service lines and plumbing remain in use in our nation, there remains a risk of lead contamination of our drinking water. Utilities, states, and schools are doing what they can to limit this risk as much as possible, but the only fail safe solution is full replacement of all lead service lines and fixtures — a massive undertaking that will require significant capital investment that is not currently available. Therefore, it is imperative that utilities and schools continue to remain vigilant about testing for and mitigating lead in drinking water, even after the public outcry from Flint has faded.

World Water Week in Stockholm is an annual event that focuses on global water issues. One of the key aspects of World Water Week is the coming together of industry experts in an effort to brainstorm and develop solutions to the world’s most pressing water-related issues.

World Water Week in Stockholm is an annual event that focuses on global water issues. One of the key aspects of World Water Week is the coming together of industry experts in an effort to brainstorm and develop solutions to the world’s most pressing water-related issues.

World Water Week is organized by the Stockholm International Water Institute (SIWI), whose vision is a water wise world where the unique value of water is recognized and where water is shared and allocated sustainably, equitably, and efficiently to meet everyone’s basic needs. This year’s theme is Water for Sustainable Growth, and also marks the 20th jubilee of the Stockholm Junior Water Prize. In 2015, over 3,300 individuals and close to 300 organizations from 130 countries participated in World Water Week.

Importance of Water for Sustainable Growth

As the global population continues to increase exponentially, it has become absolutely critical that natural resources be utilized sustainably — and water is arguably the world’s most precious resource. While water is a necessary part of every aspect of life, water availability will be of particular import in five key areas, expanded below.

Agriculture

Agriculture is not only critical to nourishing the global population, it is also far and away the most aggressive consumer of water. In fact, 70% of water withdrawals worldwide are for agriculture. Add to this the fact that by 2050 global agriculture will need to produce 60% more food in order to feed the burgeoning population, and it becomes clear that finding ways to farm sustainably is not only prudent, but necessary. The most sustainable form of agriculture comes in the form of rain fed crops. However, only about half of agriculture that has the potential to be rain fed is currently doing so. The rest is relying on irrigation and water withdrawals. Therefore, a key goal for the future is to convert these irrigated crops into ones that are watered naturally, with rainfall.

Agriculture is not only critical to nourishing the global population, it is also far and away the most aggressive consumer of water. In fact, 70% of water withdrawals worldwide are for agriculture. Add to this the fact that by 2050 global agriculture will need to produce 60% more food in order to feed the burgeoning population, and it becomes clear that finding ways to farm sustainably is not only prudent, but necessary. The most sustainable form of agriculture comes in the form of rain fed crops. However, only about half of agriculture that has the potential to be rain fed is currently doing so. The rest is relying on irrigation and water withdrawals. Therefore, a key goal for the future is to convert these irrigated crops into ones that are watered naturally, with rainfall.

Industry

The second largest consumers of water are industry and energy, which combined account for 20% of the global water demand. Most of this demand is, of course, from developed countries, since underdeveloped countries typically are dominated by agriculture. Therefore, there exists a serious imbalance in industrial water usage and concern over the future as industrialization spreads as these underdeveloped nations expand. Therefore, water experts are working together to find ways in which all nations can benefit from industrialization while avoiding unsustainable impacts on water demand as well as other natural resources.

Domestic

Domestic usage only accounts for 10% of total water demand, but its impacts are arguably the most important. Lack of improved water and sanitation is one of the largest contributors to poverty, illness, and lack of education worldwide. Even with the incredible strides made in the United Nation’s goal to provide improved water and sanitation to all people, an estimated 748 million people still lack access to an improved source of water and 2.5 billion still lack access to improved sanitation. One of the key goals of water for sustainable growth is finding ways in which to unequivocally ensure safe, clean water and hygienic, private sanitation to all inhabitants on the planet.

Domestic usage only accounts for 10% of total water demand, but its impacts are arguably the most important. Lack of improved water and sanitation is one of the largest contributors to poverty, illness, and lack of education worldwide. Even with the incredible strides made in the United Nation’s goal to provide improved water and sanitation to all people, an estimated 748 million people still lack access to an improved source of water and 2.5 billion still lack access to improved sanitation. One of the key goals of water for sustainable growth is finding ways in which to unequivocally ensure safe, clean water and hygienic, private sanitation to all inhabitants on the planet.

Ecosystems

Adding to the challenge of water for sustainable growth for agriculture, industry, and domestic usage is the fact that climate change and an ever-increasing population have created a significant impact on our environment. Sustainable development has been a buzzword for decades, and yet most efforts have been largely unsuccessful. Rainforests have been stripped, aquifers practically drained, air quality degraded, and soils contaminated. No longer can sustainable development be a catch phrase or theory – the time has come for a proactive, targeted response to the global ecological crisis, including water supply and demand. Fortunately, savvy water and ecological experts from around the globe are currently working hard towards a sustainable future for generations to come.

Cities

Currently, over half of the global population resides in cities, and that number is expected to increase to over two-thirds of the nine billion global inhabitants by 2050. Most of this increase will happen in developed nations, which will tax infrastructure and likely increase areas of impoverished living conditions. Already in the United States are areas, such as Navajo Nation and the Texas Colonias, that are in many ways similar to those in underdeveloped nations in terms of infrastructure and resource availability. And, with the influx of urban residents, those areas of substandard living conditions are likely to increase – and not just in America. In fact, it is predicted that, without proactive planning, global urban populations will almost certainly experience a serious degradation in living conditions, including inadequate water and sanitation facilities. Therefore, the sustainable development of water resources for not only economic and industrial growth, but also for social equality and justice will be key to the sustainable development of urban areas.

Currently, over half of the global population resides in cities, and that number is expected to increase to over two-thirds of the nine billion global inhabitants by 2050. Most of this increase will happen in developed nations, which will tax infrastructure and likely increase areas of impoverished living conditions. Already in the United States are areas, such as Navajo Nation and the Texas Colonias, that are in many ways similar to those in underdeveloped nations in terms of infrastructure and resource availability. And, with the influx of urban residents, those areas of substandard living conditions are likely to increase – and not just in America. In fact, it is predicted that, without proactive planning, global urban populations will almost certainly experience a serious degradation in living conditions, including inadequate water and sanitation facilities. Therefore, the sustainable development of water resources for not only economic and industrial growth, but also for social equality and justice will be key to the sustainable development of urban areas.

In Conclusion

Sustainable development of water resources is paramount for the future health and success of our planet. SIWI’s World Water Week is a way in which experts from around the world are able to meet, discuss, share ideas, and thoughtfully plan for a sustainable future. For more information on World Water Week, including updates, activities, and how you can participate, please visit www.worldwaterweek.org.