Tata & Howard designed and constructed the improvements to eliminate low and inadequate system pressures, construct a new source, pilot test filtration for manganese removal, design and construct required distribution system piping to connect the plant and storage tank with the system, design a new concrete storage tank, booster pump stations, and the filtration facility for manganese removal. The project was very successful and remains in great condition today.

Tata & Howard designed and constructed the improvements to eliminate low and inadequate system pressures, construct a new source, pilot test filtration for manganese removal, design and construct required distribution system piping to connect the plant and storage tank with the system, design a new concrete storage tank, booster pump stations, and the filtration facility for manganese removal. The project was very successful and remains in great condition today.

Markets: Small-to-Midsize Municipalities

Infiltration/Inflow Investigations in Milford, MA

Tata & Howard has been conducting Infiltration/Inflow (I/I) investigations for The Town of Milford, Massachusetts for the past several years within their collection system, which consists of approximately 90 miles of 4-inch diameter to 36-inch diameter gravity sewers and force main, ten pump stations and a 4.3 million gallon per day (MGD) advanced wastewater treatment facility. Throughout the investigations, I/I sources such as broken service connections, broken pipes, cracks, roots, and illegal connections have been identified. The I/I ranged from 144 gallons per day (gpd) to in excess of 400,000 gpd. Based on the results of previous I/I investigations, the Sewer Department was able to remove a direct connection from the street drainage system to the sewer system that resulted in the removal of an estimated 450,000 gpd of extraneous water from the sewer system, therefore regaining 10 percent of available capacity at the treatment facility.

As a result of conducting these I/I investigations, the Town has the ability significantly reduce the amount of extraneous water entering the collection system, as well as free up capacity at the treatment facility. The Town of Milford has also incorporated a 5:1 removal policy within the Town Bylaws, which requires Contractors/Builders to remove 5 gpd of I/I from the system for each gallon of wastewater proposed to be discharged, which minimizes repair costs for the Town and their residents.

Dam Rehabilitation, Meriden, CT

Baldwins Pond Dam is a stone masonry and earthen embankment dam located on Harbor Brook just upstream of Westfield Road. The dam has a length of about 200 feet and a maximum height of about 17 feet. A concrete gate chamber at the right (looking downstream) end of the spillway provides controls for the 30-inch low level outlet, which discharges through the right training wall. Access to the operator is provided through a hatch in the top of the chamber. The spillway has an overflow length of 85 feet and a stepped concrete apron at the downstream toe. The upstream embankment slope and the area downstream of the apron are protected with riprap. Baldwins Pond has a surface area of 6 acres and a tributary watershed of 8.34 square miles.

The dam was rehabilitated in 1998, designed by Tata & Howard’s Waterbury, CT office.

FEMA Hazard Mitigation Grant in MA

Tata & Howard provided engineering consulting services to the Town of Monson, Massachusetts for the relocation of the 8-inch diameter water main on Mechanic Street.

The main was originally constructed in 1897 under the streambed; however, after 117 years in this location, the decrease in surface water elevation had exposed the water main. The water level averaged about one inch below the top of pipe, exposing the top portion of the entire section of main that crossed the brook, approximately 15 linear feet of main. Exposure of the water main made it susceptible to freezing during the winter months, which could have resulted in a break and subsequent lost water or contamination from the brook to the Town’s entire water system, potentially resulting in significant costs to residents and to repair, clean, and disinfect the system. The main provides potable water to approximately fifty residents. There were only two gate valves located at the ends of Mechanic Street. As a result, if the main were to fail at the bridge, the entire street would have to be shut down in order to repair the damage, disrupting water service for the 50 serviced residents.

The Mechanic Street Bridge has a history of failure. As a result of a major flood event in 1955, the bridge failed and was completely replaced in 1956. The bridge ran directly over the water main, which posed an additional threat to the main should the failure reoccur. Although the main was unaffected during the previous failure, its weakened condition made it more susceptible to failure in a similar event.

Tata & Howard provided funding assistance and the project qualified for and received a FEMA Hazard Mitigation Grant for 75% of the cost of the project. The work included the preparation of design plans and specifications for the relocation of the 8-inch water main to a self-supporting beam structure attached to the bridge abutments on Mechanic Street. The project also included bidding, permitting, construction administration, and resident observation.

Water Treatment Plant with Dehumidification System, Whitinsville, MA

Tata & Howard provided the design of a 1.44 million gallon per day (mgd) water treatment plant to treat water from the Whitinsville Water Company’s Whitin Wellfield. The existing facilities consisted of a chemical injection facility and pump station, and historical high levels of iron and manganese led to water discoloration issues in the distribution system.

The new treatment facility for the Whitin Wellfield utilizes chlorine oxidation and GreensandPlus™ media filtration to remove iron and manganese from the raw water to concentrations below Secondary Maximum Contaminant Levels. The installation of 16-inch pipe between the existing facility and the water treatment facility is utilized in combination with filtration to provide contact time to achieve log removal of Giardia Lamblia (Giardia), Cryptosporidium, and viruses, if it becomes necessary in the future.

The treatment plant components include a three cell horizontal pressure filter vessel, a backwash water tank, and backwash pumping systems. The design also included a dehumidification system and the installation of crushed stone below the filter vessel and spent backwash tank. This allows for water to infiltrate into the ground and prevent puddling on the concrete floor in the event that condensation does occur on the equipment.

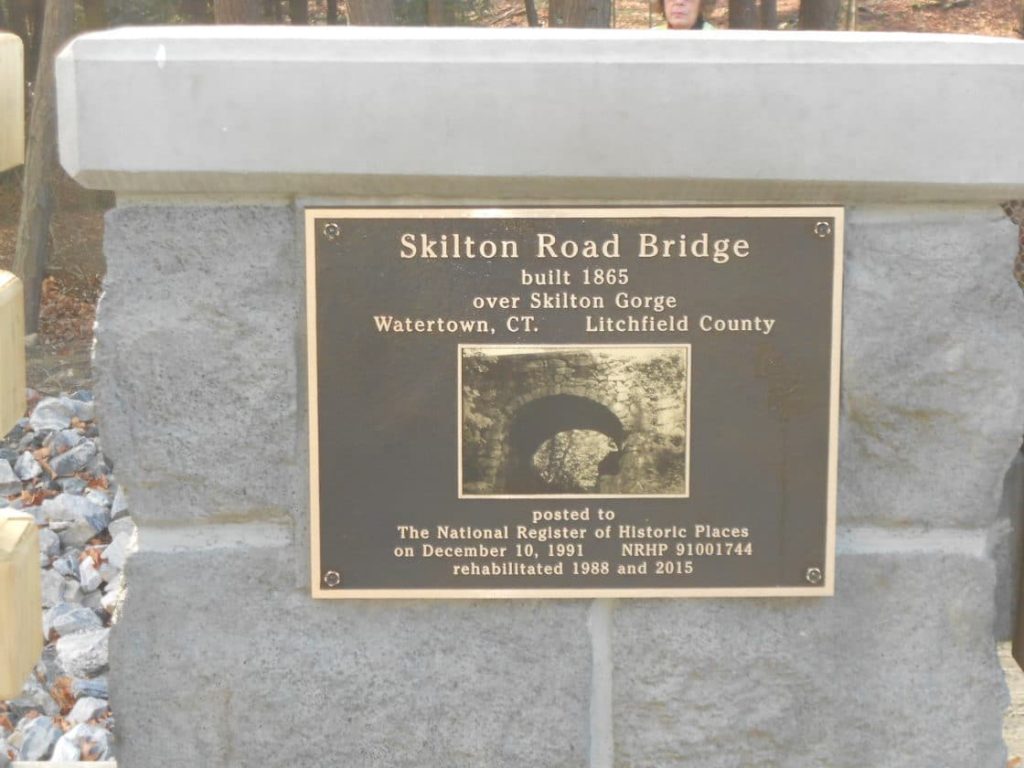

Historic Bridge Rehabilitation (circa 1865)

CLIENT: Watertown, CT

PROJECT: Skilton Road Bridge Rehabilitation

THE CHALLENGE: Skilton Road Bridge was originally built in 1865 as a one lane, dry stone masonry arch bridge over the Skilton Gorge in Watertown, Connecticut. Rehabilitation in 1988 included strengthening of the stone masonry with reinforced concrete, and adding concrete guide rails to the bridge. On December 10, 1991, Skilton Road Bridge was added to the National List of Historic Places, and in 2013, the bridge was found to be structurally deficient.

THE SOLUTION: Tata & Howard’s design for the rehabilitation and repair of the bridge required careful consideration of the historical nature of the structure. The design was approved and construction took place in 2015. All structural deficiencies were addressed and the project included the following:

- Removed existing guide rails

- Installed prestressed concrete beams across the top of the existing bridge

- Widened the bridge for two 9’ travel lanes and a sidewalk

- Installed new aluminum bridge rails covered with wood

- Repaired the stone masonry on the west abutment wall

- Added new storm drainage

PROGRESS: Construction on the Skilton Road Bridge was completed in October of 2015, and a ribbon cutting ceremony was held on December 10, 2015. The bridge maintains its historic integrity.

Dam Reconstruction, Meriden, CT

The Fosters Pond Dam reconstruction project presented several challenges. The existing spillway was inadequate to discharge the 100-year spillway design flood, and the existing dam was in extremely poor condition. The embankments lacked erosion protection and were very steep, the crest was narrow, and the outlet had fallen into disrepair, rendering it inoperable. Therefore, it was imperative that the reconstruction design of Fosters Pond Dam be designed to improve both safety and reliability, provide a functional and operable outlet, and provide ease of maintenance.

The reconstruction included the construction of new and higher reinforced concrete spillway training walls, upstream riprap erosion protection, a new reinforced concrete gate structure with 24″ inlet and outlet pipes and sluice gate, widened embankment crests to 12′, flattened slopes for ease of maintenance, and a gravel road to allow access to the embankment and gate structure. Riprap erosion protection is now provided on the upstream slopes as well as in the discharge channel. Because of these improvements, the dam can safely pass the 100-year spillway design flood with over a foot of freeboard. The length and level of the spillway weir remains unchanged.

Water System Improvements and Funding Assistance, VT

Greensboro Fire District No. 1 (GFD#1), situated on the Northern portion of the Green Mountains in Vermont, requested assistance with their water distribution and treatment systems due to deficiencies identified in a sanitary survey conducted by the State of Vermont. This contract addresses these deficiencies and provides the District a more robust covered water storage tank, secure buildings that house controls and chemicals and related equipment, emergency power generation, and water metering.

As part of the project, Tata & Howard helped GFD#1 secure funding that included a 45% USDA Grant for the originally planned project with an estimated budget of $2,900,000. During the design phase, the District lost their primary well source due to an extended drought. Tata & Howard engineers worked with the District to secure a 100% USDA grant for the cost of constructing a new municipal well source and associated emergency generator and related appurtenances.

Tata & Howard provided design, construction administration, and resident observation for the water system improvements project. Construction began in the spring of 2015 with the setup of a temporary water storage system and demolition of the existing water storage tank roof structure. Precast planks and a ballasted membrane roof were then installed, providing safe, quality water. Two new small buildings were constructed to house chemicals and water well piping and controls, along with an emergency generator to provide continuous water in case of interruption to electrical power.

Fosters Pond Dam Reconstruction

CLIENT: City of Meriden, CT

PROJECT: Fosters Pond Dam Reconstruction

THE CHALLENGE: The existing spillway is inadequate to discharge the 100-year spillway design flood, and the existing, aging dam is in very poor condition. The embankments are steep and lack erosion protection, the crest is narrow, and the outlet is in disrepair and inoperable. The reconstruction of Fosters Pond Dam needs to be designed to improve the safety and reliability of the structure, provide an operable outlet, and make the structure easier to maintain.

THE SOLUTION: The reconstruction includes constructing new, higher reinforced concrete spillway training walls, providing upstream riprap erosion protection, constructing a new reinforced concrete gate structure with 24-inch inlet and outlet pipes and sluice gate, widening the embankment crests to 12 feet, flattening the slopes for ease of maintenance, and providing a gravel road to allow access to the left (looking downstream) embankment and gate structure. Riprap erosion protection will be provided on the upstream slopes and in the discharge channel. With these improvements, the dam will be able to safely pass the 100-year spillway design flood with 1.1 feet of freeboard. The level and length of the spillway weir will remain unchanged.

Mountain Street Water Treatment Plant Valve Replacement

CLIENT: Northampton, Massachusetts

PROJECT: Mountain Street Water Treatment Plant Valve Replacement

THE CHALLENGE: The three check valves on the clarifier influent feed lines were failing and, as a result, the disc was consistently hitting the downstream pipe spool piece, eventually causing each section to develop holes and leaks.

THE SOLUTION: Rather than simply replacing the check valves with the same style valve, we decided to dig deeper. We believed the discs were failing due to turbulence generated by an upstream modulating valve, so we researched alternative valves. We found that most alternative valves required a longer lay length than the existing check valves, which would have required replacement of the influent piping as well as reconfiguration of the valves and flow meters on each of the clarifier influents that feed the three units back to the header.

With additional research, we identified a flanged duckbill check valve that could actually be inserted between two flanges within the pipe, with the flange of the check valve sandwiched between the two flanges of the existing pipe configuration. The valve itself was located within the influent piping and allowed for installation without having to significantly alter the clarifier influent piping. As a result, the Owner saved on the cost of the valve replacement as well as avoided an extended shutdown time, as each clarifier would have been out of service for a far longer duration if extensive influent piping modifications were necessary.

PROGRESS: The project was successfully completed in October of 2014.