CLIENT: The Towns of Canaan, VT and Stewartstown, NH

PROJECT: Shared Wastewater Treatment Facility

THE CHALLENGE: The existing wastewater treatment facility was 40 years old, costly to operate, and did not meet state and federal water quality standards. In addition, the Towns had very limited funds with which to upgrade the treatment facility.

THE SOLUTION: Tata & Howard helped the Towns secure a $2.412 million low-interest, long-term loan and $1.69 million in grant funds from the U.S. Department of Agriculture (USDA) Rural Development in order to build the new facility.

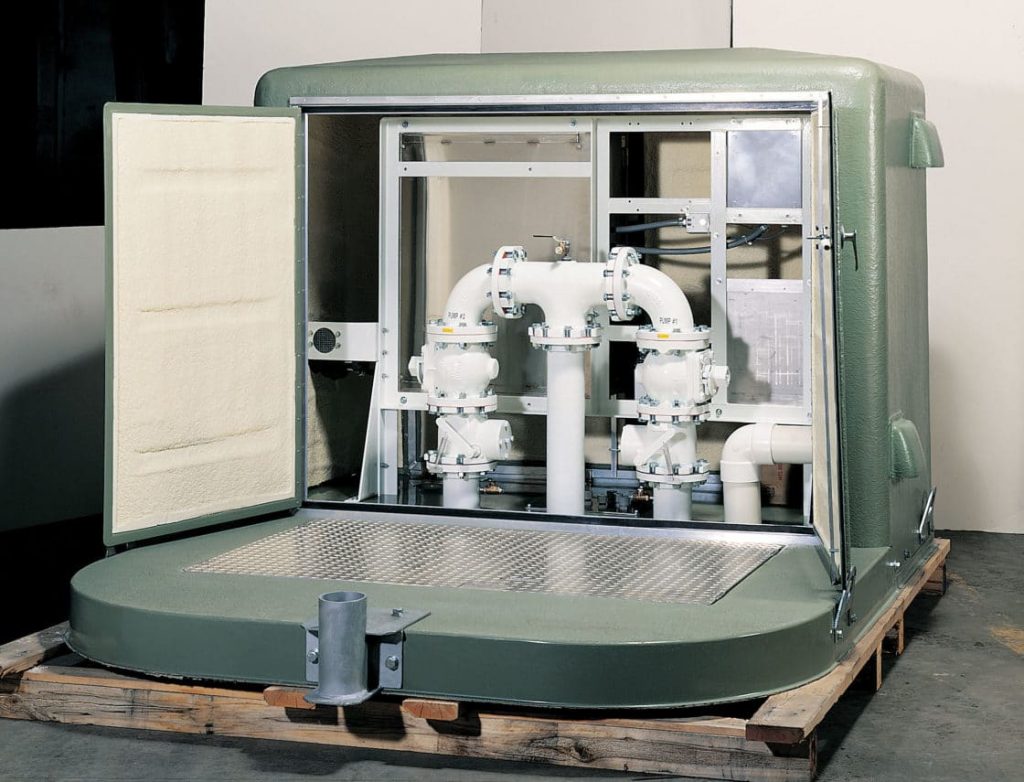

Tata & Howard, Inc. provided complete consulting engineering services for the construction of the wastewater treatment facility project which included the complete upgrade of four pump stations as well as the upgraded 0.185 mgd, 3-cell lagoon wastewater treatment facility. In addition, Tata & Howard’s St. Johnsbury, Vermont office, formerly Leach Engineering Consultants, provided full design services for all of the upgrades.

The Towns now enjoy a state-of-the-art, reliable wastewater treatment facility that meets the Effluent Discharge limits to the Connecticut River and provides for a more efficient treatment process. The new influent screening and grit removal processes extend the life of the treatment facility components. In addition, septage receiving provides for additional income and also provides service to the residents of the Towns that are not on public sewer.

The design included numerous energy-efficient features such as variable-frequency drives (VFDs) on aeration blowers, solar-powered lagoon mixers, a wood pellet boiler for heat, energy-efficient windows, and insulated concrete form (ICF) walls, resulting in a reduction in annual operation and maintenance costs. The pump stations were upgraded to eliminate operators entering below grade structures and to allow for future pump replacement that would be lower cost with it would be with the original centrifugal pumps.

PROGRESS: The project is complete, and the Towns celebrated the completion of their shared $4.12 million wastewater treatment facility with a ribbon-cutting ceremony in Canaan, VT.