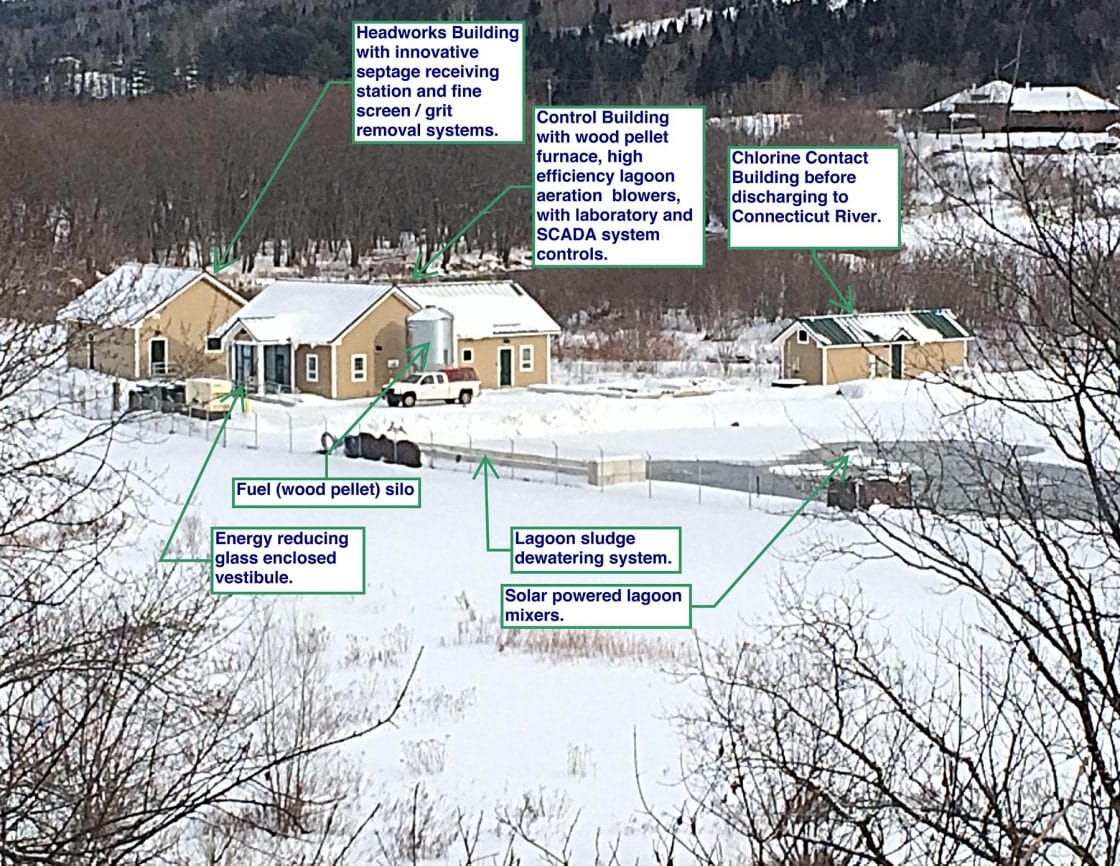

The Towns of Canaan, Vermont and Stewartstown, New Hampshire operate a shared wastewater treatment facility, which required significant upgrades. The existing facilities were 40 years old and although a few upgrades were performed in the 90s, the facilities were not performing well, did not meet Life Safety codes, and required significant maintenance. The upgrade met all of the goals of the Client by providing for simple operation and maintenance requirements, meeting the Life Safety codes, eliminating confined spaces, lowering of electrical power costs, and meeting discharge parameters through production of high quality effluent. The solutions developed for the upgrade to this facility were also economical.

One of the primary elements of the design was the consideration of the economics of energy reduction. The design incorporated insulated concrete form construction for the building walls with R-49 insulation rating in the ceilings. The design also included a wood pellet boiler with a pellet silo and hot water heating system, which allowed for reduction of explosion proof heaters in the headworks building. All of the windows were low-E and highly insulated, and an outer glassed-in entry way increased the solar gain retention of the building and reduced heat loss. he process headworks and operations buildings were constructed as single story structures, increasing operator safety.

The lagoon aeration system is now a fine bubble, highly efficient process with additional mixing provided by solar powered mixers that help reduce aeration requirements, improve treatment, and allows for the addition of septage, all at no cost due to solar power. The pump station upgrades were designed to eliminate daily confined space entry by the operator by the conversion to submersible pumps. For sludge removal, a unique and simple “Sludge Sled” system was incorporated, which allows the operators to easily remove the sludge at their convenience. Sludge treatment is accomplished with a geo-bag system that allows the sludge to be freeze dried, reducing the volume by almost 50% with no energy consumption.

The influent pump station was designed with three pumps instead of the normal two-pump system in order to meet both present and future design flows, allow for lower horsepower pumps, improve flexibility, reduce replacement costs, and reduce energy costs. The other four deep dry pit pump stations were converted to wet wells and submersible pumps, eliminating confined spaces, and are equipped with emergency generators, eliminating the need for operator attention when power is lost.

The incorporation of highly energy efficient building components resulted in reducing annual operation and maintenance costs, which resulted in lower user rates and a more sustainable facility. All building components are virtually maintenance free. All of the equipment and processes were selected to reduce both annual and future replacement costs.

The treatment system is a 3-cell aerated lagoon system, and the solar powered mixers were installed to enable reduction of the aeration needs and horsepower during the summer months when septage is added. The aeration blowers, which are housed in insulated enclosures, reduce noise and were sized to allow for the addition of septage to the lagoons, which is not common in Vermont. The aeration blowers are controlled with Variable Frequency Drives (VFDs), which allow for greater operator control of aeration and provide energy cost savings. The operation is simple and safe for operators and others who need to maintain the facility and equipment. The design has provided flexibility to the operators and has resulted in an energy efficient, sustainable solution for this community.