As those in the industry well know, water and wastewater treatment plants use an exorbitant amount of energy. In fact, 30-40% of total municipal energy consumption is due to water and wastewater treatment plants. In addition, energy currently accounts for 40% of drinking water systems’ operational costs and is projected to jump to 60% within the next 15 years. This excessive energy consumption places financial burden on already stressed water and wastewater utilities struggling to keep up with ever-increasing regulations and demand.

As those in the industry well know, water and wastewater treatment plants use an exorbitant amount of energy. In fact, 30-40% of total municipal energy consumption is due to water and wastewater treatment plants. In addition, energy currently accounts for 40% of drinking water systems’ operational costs and is projected to jump to 60% within the next 15 years. This excessive energy consumption places financial burden on already stressed water and wastewater utilities struggling to keep up with ever-increasing regulations and demand.

The Electric Power Research Institute (EPRI) conducted studies on wastewater treatment plants and cautions that as treatment requirements increase, energy requirements will also increase. EPRI also projects that as treatment requirements increase, the energy required to treat wastewater utilizing conventional technologies will increase exponentially. For example, new membrane bioreactor (MBR) processes actually consume 30-50% more electricity than plants that utilize more advanced treatment with nitrification. Also, plants that incorporate nanofiltration or reverse osmosis to meet stringent effluent utilize nearly twice the energy. EPRI further projects that strict nitrogen and phosphorus removal will be increasingly required, necessitating the incorporation of these energy-intensive technologies.

And let’s not forget the environment. Drinking water and wastewater systems add over 45 million tons of greenhouse gases annually, contributing to the already problematic issue of climate change. Bringing the issue full circle, climate change directly affects both the availability and the quality of our drinking water supply. The importance of incorporating energy efficiency into water and wastewater operations is paramount to these systems’ future sustainability.

Case Studies

Canaan, VT and Stewartstown, NH Shared Wastewater Treatment Plant Upgrades

The Towns of Canaan, Vermont and Stewartstown, New Hampshire operate a shared wastewater treatment facility, which required significant upgrades. The existing facilities were 40 years old and although a few upgrades were performed in the 90s, the facilities were not performing well, did not meet Life Safety codes, and required significant maintenance.

One of the primary elements of the design was the consideration of the economics of energy reduction. The design incorporated insulated concrete form construction for the building walls with R-49 insulation rating in the ceilings. The design also included a wood pellet boiler with a pellet silo and hot water heating system, which allowed for reduction of explosion proof heaters in the headworks building. All of the windows were low-E and highly insulated, and an outer glassed-in entry way increased the solar gain retention of the building and reduced heat loss. The process headworks and operations buildings were constructed as single story structures, increasing operator safety. The lagoon aeration system is now a fine bubble, highly efficient process with additional mixing provided by solar powered mixers that help reduce aeration requirements, improve treatment, and allows for the addition of septage, all at no cost due to solar power.

The pump station upgrades were designed to eliminate daily confined space entry by the operator by the conversion to submersible pumps. For sludge removal, a unique and simple “Sludge Sled” system was incorporated, which allows the operators to easily remove the sludge at their convenience. Sludge treatment is accomplished with a geo-bag system that allows the sludge to be freeze dried, reducing the volume by almost 50% with no energy consumption. The influent pump station was designed with three pumps instead of the normal two-pump system in order to meet both present and future design flows, allow for lower horsepower pumps, improve flexibility, reduce replacement costs, and reduce energy costs. The other four deep dry pit pump stations were converted to wet wells and submersible pumps, eliminating confined spaces, and are equipped with emergency generators, eliminating the need for operator attention when power is lost.

The incorporation of highly energy efficient building components resulted in reducing annual operation and maintenance costs, which resulted in a more sustainable facility. All of the equipment and processes were thoughtfully selected to reduce both annual and future replacement costs.

The treatment system is a 3-cell aerated lagoon system, and the solar powered mixers were installed to enable reduction of the aeration needs and horsepower during the summer months when septage is added. The aeration blowers, which are housed in insulated enclosures, reduce noise and were sized to allow for the addition of septage to the lagoons, which is not common in Vermont. The aeration blowers are controlled with Variable Frequency Drives (VFDs), which allow for greater operator control of aeration and provide energy cost savings. The operation is simple and safe for operators and others who need to maintain the facility and equipment. The design has provided flexibility to the operators and has resulted in an energy efficient, sustainable solution for this community.

Shrewsbury, MA Home Farm Water Treatment Plant Design

The Home Farm Water Treatment Plant (WTP) in Shrewsbury, Massachusetts was originally constructed in 1989. Although the WTP is still fully functional, its treatment capabilities are limited to chemical addition and air strippers for VOC removal, and the plant is capable of treating 6.0 million gallons per day (mgd). Manganese is present at all Home Farm wells, with widely varying levels from a low 0.03 parts per million (ppm) to a high 0.7 ppm. The existing treatment plant sequesters manganese, but does not have the ability to remove it from finished water.

Three treatment methodologies were piloted. The first two were greensand and pyrolucite, both commonly implemented catalytic media options for removing manganese and iron. The third was Mangazur®, a new technology. Mangazur® filter media contains the microscopic organism leptothrix ochracea, which consumes manganese and is naturally occurring in groundwater. Through consumption, the microbes oxidize the manganese to a state where it can precipitate onto the media. Unlike other media, Mangazur® does not require regeneration due to the continuous growth of microbes within the filter. Mangazur® technology also does not require chemical addition for pre-oxidation, minimizing the amount of chemical required for the plant.

Pilot testing for the biological treatment was performed over five one-week trials. Test parameters included a long shut-down on the filters, adding pre-oxidant, and adjusting pH or dissolved oxygen. The results of the testing indicated that although the Mangazur® does require a correct dissolved oxygen level and pH, it does not require a pre-oxidant, making the only chemical addition necessary for pretreatment potassium hydroxide for pH adjustment. Filter backwash efficiency is also a major benefit of the Mangazur® technology for the Home Farm application. With loading rates twice that of traditional catalytic media and filter runs exceeding 96 hours, the Town would only need to backwash the four filters once every four days rather than eight filters every day, saving a significant amount of water. The backwash flow rate and duration are also significantly lower for Mangazur® filters than for other traditional filter options. The results of the pilot tests indicated that all technologies were viable options to reduce manganese levels below 0.05 ppm; however, the biological treatment was the most efficient option.

Since the existing chemical feed equipment in the plant is aging and the existing building itself was also in need of rehabilitation, the decision was made to construct an entirely new standalone 7.0 mgd facility. The new facility will feature many energy efficient features including translucent panels for lighting efficiency, high efficiency water fixtures, high efficiency lighting, and stormwater bioretention areas for drainage. In addition, while the existing building will be demolished, the concrete slab slab will be kept for future installation of solar panels. The new facility also contains three deep bubble aerators for VOC removal. While Mangazur® technology has been approved in one other municipality in Massachusetts, there are few treatment plants in the northeast using this technology, and of those treatment plants, none have a design capacity above 5.0 mgd. Home Farm has a much higher design capacity and will be the largest Mangazur® water treatment plant in the northeast once completed. The Mangazur® filters at Home Farm will have the second highest design capacity in the country, after a 26.0 mgd treatment plant in Lake Havasu City, Arizona.

Download the complete whitepaper on the Mangazur™ Home Farms Water Treatment Plant here.

Flagstaff, AZ Water Reclamation Facility Upgrades

Tata & Howard provides on-call engineering services for water, wastewater, and energy related projects for the City of Flagstaff, Arizona. Several options for replacement of the blowers were evaluated and presented to the City in a report that recommended the installation of appropriately sized turbo blowers and upgrading the controls logic to automate dissolved oxygen controls.

Tata & Howard provides on-call engineering services for water, wastewater, and energy related projects for the City of Flagstaff, Arizona. Several options for replacement of the blowers were evaluated and presented to the City in a report that recommended the installation of appropriately sized turbo blowers and upgrading the controls logic to automate dissolved oxygen controls.

The City had been experiencing long term maintenance issues with the existing biogas piping at the Wildcat Wastewater Reclamation Facility. The piping to the co-generator was not providing an adequate supply of gas from the digesters which, if operating, could save the City approximately $200,000 in annual power costs. The goals of this project were the restoration of the ability to run the generator on biogas, utilize the heat generated by the sludge digestion process to further reduce energy costs, reduce maintenance time to operate the biogas system, and have a positive impact on the environment, since methane is one of the most potent greenhouse gases.

In addition, Tata & Howard conducted an energy efficiency study on the aeration blowers and pumps at two treatment plants. Pumping systems had efficiencies as low as 20%. Pumps and blowers were oversized to meet peak and future demands but not efficient at low flows or off peak flows. The testing showed that modifications to these systems had the potential to save the City approximately $250,000 in annual electrical costs and $445,000 in APS rebate funds for the modifications.

Download a case study on the energy efficiency project in Flagstaff, AZ here.

In Conclusion

While these three case studies are all extremely different projects, the goals are the same: increased energy efficiency, greener operations, and sustainability, all while meeting project objectives, budgets, and deadlines. Increasing energy efficiency in water and wastewater treatment is no longer optional; rather, it is a necessity to remain operational by meeting both budgetary and sustainability objectives. By incorporating innovative thinking and tailored methodologies into rehabilitation and repair projects, water and wastewater systems can ensure sustainable operations and a greener environment while protecting our world’s most precious resource for generations to come.

Tata & Howard, Inc. is pleased to announce that Jerald A. Postema has joined the firm as Client Service Specialist. Mr. Postema brings over 44 years of water and wastewater operations and management experience to the team and will lead the firm’s business development efforts in the southwest. He is working out of the company’s Goodyear, Arizona office.

Tata & Howard, Inc. is pleased to announce that Jerald A. Postema has joined the firm as Client Service Specialist. Mr. Postema brings over 44 years of water and wastewater operations and management experience to the team and will lead the firm’s business development efforts in the southwest. He is working out of the company’s Goodyear, Arizona office. Each municipality and utility is responsible for making sure that its assets, including water, wastewater, and/or stormwater systems, stay in good working order, regardless of the age of its components or the availability of additional funds. This requirement makes properly maintaining and monitoring assets paramount. With limited resources, an asset management plan can help municipalities and utilities maximize the value of their capital as well as their operations and maintenance dollars. Asset management is a scalable approach that can be utilized by all types of systems, of any size.

Each municipality and utility is responsible for making sure that its assets, including water, wastewater, and/or stormwater systems, stay in good working order, regardless of the age of its components or the availability of additional funds. This requirement makes properly maintaining and monitoring assets paramount. With limited resources, an asset management plan can help municipalities and utilities maximize the value of their capital as well as their operations and maintenance dollars. Asset management is a scalable approach that can be utilized by all types of systems, of any size. The

The  It is apparent that financial planning for municipalities and utilities must be based on sound asset condition projections from an engineering and operations perspective – not just financial assumptions. Customers are often adamantly against rate and tax increases; however, these sometimes-unavoidable increases are easier for customers to understand — and accept — when they are backed up with clear data showing exactly what system improvements are needed and why. There are many costs associated with municipality and utility operations and maintenance. One of these is the cost of asset ownership, a cost element not currently present in the audited financial statements of many municipalities and utilities. An asset management approach can aid municipalities and utilities in understanding the true costs associated with ownership and operation along with complying with government regulations.

It is apparent that financial planning for municipalities and utilities must be based on sound asset condition projections from an engineering and operations perspective – not just financial assumptions. Customers are often adamantly against rate and tax increases; however, these sometimes-unavoidable increases are easier for customers to understand — and accept — when they are backed up with clear data showing exactly what system improvements are needed and why. There are many costs associated with municipality and utility operations and maintenance. One of these is the cost of asset ownership, a cost element not currently present in the audited financial statements of many municipalities and utilities. An asset management approach can aid municipalities and utilities in understanding the true costs associated with ownership and operation along with complying with government regulations. Finding and detecting failures such as leaks in the system

Finding and detecting failures such as leaks in the system

It is widely known how important water is to our lives and the world we live in. Our body and planet is comprised of about 70% water – making it seem like it is easily accessible and plentiful. However, when you rule out our oceans and ice caps, less than 1% of all the water on Earth is drinkable. Of that less than 1%, groundwater only accounts for 0.28% of fresh water around the globe. Safe drinking water is a privilege we often take for granted while we brush our teeth or drink a glass of water in the morning. While we are giving thanks to our family, friends, and food during Thanksgiving, we should also give big thanks for our clean drinking water and the people who make it happen.

It is widely known how important water is to our lives and the world we live in. Our body and planet is comprised of about 70% water – making it seem like it is easily accessible and plentiful. However, when you rule out our oceans and ice caps, less than 1% of all the water on Earth is drinkable. Of that less than 1%, groundwater only accounts for 0.28% of fresh water around the globe. Safe drinking water is a privilege we often take for granted while we brush our teeth or drink a glass of water in the morning. While we are giving thanks to our family, friends, and food during Thanksgiving, we should also give big thanks for our clean drinking water and the people who make it happen.

Imagine a day without water. Nearly every single thing we do is reliant on water. Right at the start of our day, we would not be able to use the bathroom, take a shower, brush our teeth, or make a cup of coffee. There would be no cleaning dishes, mopping floors, or cooking food. Water is something we use constantly throughout the day without even thinking about it, and has therefore become something we take for granted. For that reason, Imagine a Day Without Water was first introduced in 2015 in order to bring awareness to the value of water.

Imagine a day without water. Nearly every single thing we do is reliant on water. Right at the start of our day, we would not be able to use the bathroom, take a shower, brush our teeth, or make a cup of coffee. There would be no cleaning dishes, mopping floors, or cooking food. Water is something we use constantly throughout the day without even thinking about it, and has therefore become something we take for granted. For that reason, Imagine a Day Without Water was first introduced in 2015 in order to bring awareness to the value of water. Think about the way water enters our homes and businesses, and of how our wastewater leaves it. There are literally thousands of pipes underground that we never see, and many of these pipes are approaching the end of their useful life. After all, most of our infrastructure was built around the time of World War II, and is now over 70 years old. In fact, much of the infrastructure in New England is well over 100 years old. These pipes and treatment plants are in desperate need of repair and replacement. In addition, our drinking water is treated to meet increasingly stringent regulations that protect our health. Bacteria, toxins, metals, and other harmful substances are all removed from the water prior to it entering the distribution system, and this treatment is expensive. In the same way, the wastewater that leaves our homes and businesses is highly treated and cleaned before it is returned to the environment, protecting public health from the myriad toxins and diseases found in untreated wastewater.

Think about the way water enters our homes and businesses, and of how our wastewater leaves it. There are literally thousands of pipes underground that we never see, and many of these pipes are approaching the end of their useful life. After all, most of our infrastructure was built around the time of World War II, and is now over 70 years old. In fact, much of the infrastructure in New England is well over 100 years old. These pipes and treatment plants are in desperate need of repair and replacement. In addition, our drinking water is treated to meet increasingly stringent regulations that protect our health. Bacteria, toxins, metals, and other harmful substances are all removed from the water prior to it entering the distribution system, and this treatment is expensive. In the same way, the wastewater that leaves our homes and businesses is highly treated and cleaned before it is returned to the environment, protecting public health from the myriad toxins and diseases found in untreated wastewater. Another challenge faced by utilities today is our growing national population combined with historic drought and climate change. This increased demand in the wake of a dwindling supply is placing extra pressure on our water and wastewater systems, and requires thoughtful, long-term solutions if we are going to be able to meet current and future demands. Add to that the recent focus on our nation’s lead service lines and the fact that they absolutely need to be replaced, and it becomes clear that our water and wastewater systems are in desperate need of attention — and investment.

Another challenge faced by utilities today is our growing national population combined with historic drought and climate change. This increased demand in the wake of a dwindling supply is placing extra pressure on our water and wastewater systems, and requires thoughtful, long-term solutions if we are going to be able to meet current and future demands. Add to that the recent focus on our nation’s lead service lines and the fact that they absolutely need to be replaced, and it becomes clear that our water and wastewater systems are in desperate need of attention — and investment. We have reached the point where we must proactively address and invest in our nation’s water and wastewater infrastructure — before it is too late. Imagine a Day Without Water is a day in which we can all spread the word about the value of water by encouraging friends, family, and colleagues to imagine what their lives would be like without water. With proper planning and smart investment from both consumers and our legislators, living without water is something that will never come to fruition in our nation. Join the movement today by participating in Imagine a Day Without Water. For the many no-cost ways in which you can participate, including signing a petition, joining a Thunderclap, and becoming involved on social media, please visit

We have reached the point where we must proactively address and invest in our nation’s water and wastewater infrastructure — before it is too late. Imagine a Day Without Water is a day in which we can all spread the word about the value of water by encouraging friends, family, and colleagues to imagine what their lives would be like without water. With proper planning and smart investment from both consumers and our legislators, living without water is something that will never come to fruition in our nation. Join the movement today by participating in Imagine a Day Without Water. For the many no-cost ways in which you can participate, including signing a petition, joining a Thunderclap, and becoming involved on social media, please visit  Water and wastewater utilities across the country face common challenges. These include rising costs, aging infrastructure, increasingly stringent regulatory requirements, population changes, and a rapidly changing workforce. While many utilities find themselves turning from one urgent priority to the next, others have implemented effective operational efficiency initiatives that have helped them enhance the stewardship of their infrastructure, improve performance in many critical areas, and respond to current and future demands. Improved efficiency is not just beneficial to a utility’s bottom line – it benefits everyone in a community.

Water and wastewater utilities across the country face common challenges. These include rising costs, aging infrastructure, increasingly stringent regulatory requirements, population changes, and a rapidly changing workforce. While many utilities find themselves turning from one urgent priority to the next, others have implemented effective operational efficiency initiatives that have helped them enhance the stewardship of their infrastructure, improve performance in many critical areas, and respond to current and future demands. Improved efficiency is not just beneficial to a utility’s bottom line – it benefits everyone in a community. A common problem facing many utilities today is a retiring work force. By implementing operational efficiency now, utilities can recruit and retain a workforce that is competent, adaptive, and correctly trained to take on leadership roles of their own. Through communication and effective training, utility owners and operators can create an organization focused on continual learning and improvement. This ensures employee knowledge is retained and improved upon. Over time, senior knowledge and best practices will be passed along to promote a well-coordinated senior leadership team who understands their system and the needs of its customers.

A common problem facing many utilities today is a retiring work force. By implementing operational efficiency now, utilities can recruit and retain a workforce that is competent, adaptive, and correctly trained to take on leadership roles of their own. Through communication and effective training, utility owners and operators can create an organization focused on continual learning and improvement. This ensures employee knowledge is retained and improved upon. Over time, senior knowledge and best practices will be passed along to promote a well-coordinated senior leadership team who understands their system and the needs of its customers. Some practices that utilities are implementing greatly help to improve resiliency and reduce vulnerability to an ever changing climate. Internal practices and initiatives such as energy conservation, solar energy, and utilizing heat transformed into energy from sewage and digestion have helped utilities rely less on the grid and more on their own operations. This is especially beneficial considering the ever-increasing price of energy. Reducing energy use significantly lowers operational costs for utilities – freeing up dollars for future initiatives or infrastructure improvements. Utilities who practice operational efficiency understand that making internal practices more efficient results in the entire distribution system becoming more efficient.

Some practices that utilities are implementing greatly help to improve resiliency and reduce vulnerability to an ever changing climate. Internal practices and initiatives such as energy conservation, solar energy, and utilizing heat transformed into energy from sewage and digestion have helped utilities rely less on the grid and more on their own operations. This is especially beneficial considering the ever-increasing price of energy. Reducing energy use significantly lowers operational costs for utilities – freeing up dollars for future initiatives or infrastructure improvements. Utilities who practice operational efficiency understand that making internal practices more efficient results in the entire distribution system becoming more efficient.

The truth is, there is too much at stake to keep ignoring our weakening infrastructure. If we do not do something soon, Americans may be in for some serious surprises. Imagine not being able to drink the water that comes out of our faucets or even take a shower without worrying about water borne diseases and bacteria. If we wish to seriously improve our water infrastructure, we need collaboration from all parties, both public and private. Politicians and lawmakers need to take definitive action and commit to a sustainable and reliable plan to make our water systems safe and adequate for the future. We need to make the condition of our country’s water systems a top priority.

The truth is, there is too much at stake to keep ignoring our weakening infrastructure. If we do not do something soon, Americans may be in for some serious surprises. Imagine not being able to drink the water that comes out of our faucets or even take a shower without worrying about water borne diseases and bacteria. If we wish to seriously improve our water infrastructure, we need collaboration from all parties, both public and private. Politicians and lawmakers need to take definitive action and commit to a sustainable and reliable plan to make our water systems safe and adequate for the future. We need to make the condition of our country’s water systems a top priority. Wastewater. It’s something that will always exist, and will always require collection and treatment. Just like improved water, improved sanitation is one of the key contributing factors to a developed nation, significantly improving public health, educational opportunity, and workforce viability. And while the United States boasts nearly 100% improved water and sanitation, there is still cause for concern.

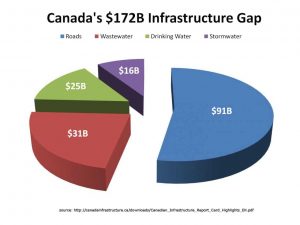

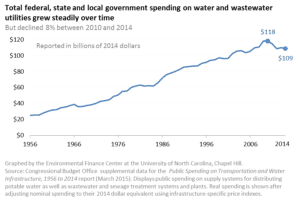

Wastewater. It’s something that will always exist, and will always require collection and treatment. Just like improved water, improved sanitation is one of the key contributing factors to a developed nation, significantly improving public health, educational opportunity, and workforce viability. And while the United States boasts nearly 100% improved water and sanitation, there is still cause for concern. In March of 2015, the Congressional Budget Office (CBO) published a report on annual government expenditures on infrastructure, titled

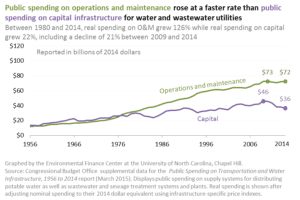

In March of 2015, the Congressional Budget Office (CBO) published a report on annual government expenditures on infrastructure, titled  To further complicate matters, capital expenditure has decreased at a faster rate than O&M expenditure. From 1956 to 1980, public spending was basically split between capital expenditures — to build or replace water and wastewater systems — and O&M of the systems. However, since 1980, O&M spending continued to grow at an annual rate of 4%-6% to the 1990s, and then at an annual rate of 1%-3% through 2009, since when it has remained flat. In contrast, capital spending grew at an annual rate of only about 1%-2% since 1980, and has declined at an average annual rate of 4% since 2009. Governments now spend twice as much on O&M of their existing systems than on capital expenditures to repair, rehabilitate, or replace existing assets or for the installation of new infrastructure. In addition, state and local government is now saddled with nearly the full burden of capital expenditure, as federal spending has been steadily on the decline since 1976.

To further complicate matters, capital expenditure has decreased at a faster rate than O&M expenditure. From 1956 to 1980, public spending was basically split between capital expenditures — to build or replace water and wastewater systems — and O&M of the systems. However, since 1980, O&M spending continued to grow at an annual rate of 4%-6% to the 1990s, and then at an annual rate of 1%-3% through 2009, since when it has remained flat. In contrast, capital spending grew at an annual rate of only about 1%-2% since 1980, and has declined at an average annual rate of 4% since 2009. Governments now spend twice as much on O&M of their existing systems than on capital expenditures to repair, rehabilitate, or replace existing assets or for the installation of new infrastructure. In addition, state and local government is now saddled with nearly the full burden of capital expenditure, as federal spending has been steadily on the decline since 1976.

Hydraulic modeling

Hydraulic modeling To continue as a leading industrialized nation, our wastewater utilities must not only remain safe and functional, but also progressive and up to date with current and future regulations. Because funding is declining while costs and population are increasing, it is more important than ever for wastewater utilities to methodically prioritize and plan all repairs and improvements. Only through the implementation of a well-researched and systematic course of action will utilities be prepared to provide safe and dependable wastewater services both now and in the future.

To continue as a leading industrialized nation, our wastewater utilities must not only remain safe and functional, but also progressive and up to date with current and future regulations. Because funding is declining while costs and population are increasing, it is more important than ever for wastewater utilities to methodically prioritize and plan all repairs and improvements. Only through the implementation of a well-researched and systematic course of action will utilities be prepared to provide safe and dependable wastewater services both now and in the future.